Product information

-

Lineup in Japan

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

-

FRENIC-HVAC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-Eco

-

Product information

- Product appearance

- Exploded view of main body

- Keypad switches and functions

- Monitor display & key operation

- New energy-saving

- Long life design of inverters

- Simplified maintenance

- Optimum functions for HVAC

- Environment and panel design

- Operator-friendly features

- Network compatibility

- Global compatibility

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Lift(LM1S)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in Europe

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

- FVR-Micro

-

FRENIC-HVAC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-Eco

-

Product information

- Product appearance

- Exploded view of main body

- Keypad switches and functions

- Monitor display & key operation

- New energy-saving

- Long life design of inverters

- Simplified maintenance

- Optimum functions for HVAC

- Environment and panel design

- Operator-friendly features

- Network compatibility

- Global compatibility

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-AQUA

-

FRENIC-Lift(LM1S)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-Lift(LM2A)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in North America

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

-

FRENIC-HVAC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-Eco

-

Product information

- Product appearance

- Exploded view of main body

- Keypad switches and functions

- Monitor display & key operation

- New energy-saving

- Long life design of inverters

- Simplified maintenance

- Optimum functions for HVAC

- Environment and panel design

- Operator-friendly features

- Network compatibility

- Global compatibility

- Variation

- Specifications

- External Dimensions

-

Catalog Download

-

Product information

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in China

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

- FVR-Micro

-

FRENIC VP

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

-

For Europe

- For China

-

- Document Download

- FRENIC-Lift(LM1S)

- FRENIC-eRHR

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in Asia

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

- FVR-Micro

-

FRENIC-HVAC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-Eco

-

Product information

- Product appearance

- Exploded view of main body

- Keypad switches and functions

- Monitor display & key operation

- New energy-saving

- Long life design of inverters

- Simplified maintenance

- Optimum functions for HVAC

- Environment and panel design

- Operator-friendly features

- Network compatibility

- Global compatibility

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-AQUA

- FRENIC eHVAC

-

FRENIC-Lift(LM1S)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in Taiwan

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

-

FRENIC-Eco

-

Product information

- Product appearance

- Exploded view of main body

- Keypad switches and functions

- Monitor display & key operation

- New energy-saving

- Long life design of inverters

- Simplified maintenance

- Optimum functions for HVAC

- Environment and panel design

- Operator-friendly features

- Network compatibility

- Global compatibility

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Lift(LM1S)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in Korea

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

- FRENIC-Eco

-

FRENIC-Lift(LM1S)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

For the various consumable parts inside the inverter, their designed lives have been extended to 10 years, which also extended the equipment maintenance cycles.

-

1.

Enhanced durability of the cooling fan operated under the environmental impact

-

2.

Adoption of copper bars plated with nickel or tin

In MEGA, resistance to the environmental impact has been increased compared with the conventional model (FRENIC5000 G11S/P11S). However, examine the use of the inverter carefully according to the environment in the following cases:

a. Environment is subject to sulfide gas (at tire manufacturer, paper manufacturer, sewage disposer, or part of the process in textile industry).

b. Environment is subject to conductive dust or foreign materials (in metalworking, operation using extruding machine or printing machine, waste disposal).

c. Others: The inverter is used in the environment of which specification exceeds the specified range.

If you are examining use of the inverter under the above conditions, consult the Fuji's Sales Division regarding the models with enhanced durability.

MEGA complies with European regulations that limit the use of specific hazardous substances (RoHS) as a standard. This inverter is environment-friendly as the use of the following six hazardous substances is restricted.

<Six hazardous substances>

Lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyl (PBB), and polybrominated biphenyl ether (PBDE)

-

*

-

Except the parts of some inverter models

<About RoHS>

The Directive 2011/65/EU, promulgated by the European Parliament and European Council, limits the use of specific hazardous substances included in electrical and electronic devices.

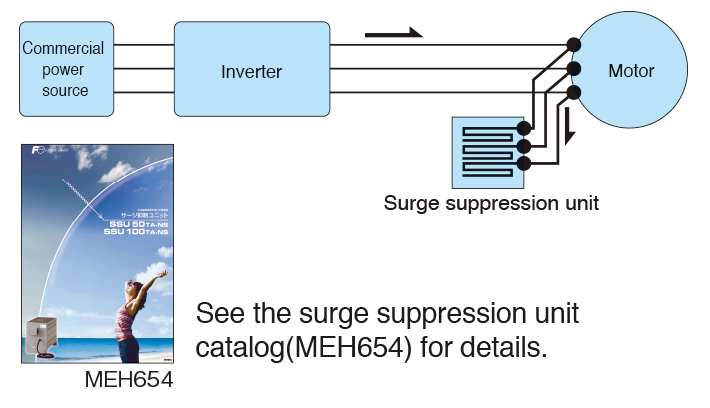

If the motor drive cable between the inverter and the motor is long, a very short surge voltage (micro surge) is generated at the motor connection ends. This surge voltage causes deterioration of the motor, dielectric breakdown, or increase in noise. The surge suppression unit suppresses this surge voltage.

-

1.

The surge voltage can be significantly suppressed simply by connecting the surge suppression unit to the motor.

-

2.

Since no additional work is required, it can be easily mounted on the existing equipment.

-

3.

The unit is applicable to the motors regardless of their capacity.

-

4.

The unit requires no power source and no maintenance.

-

5.

There are two models available depending on the cable length between the inverter and the motor: 50m and 100m.

-

6.

Compliant with environmental standard and safety standard (Compliant with RoHS Directives, and application to UL standard pending).