FRENIC-Lift (LM1S)

Product information

-

A braking circuit is built in the AC Drives of all the capacities.

-

Built-in PG feedback circuit is standard equipment.

-

An optional keypad is available.

-

Overload capacity: 200% for 10s (Note1)

-

Current response (ACR):500Hz

-

Reduction of torque ripple realizes low vibration.

-

Reduced roll-back during starting up.

-

Note1

-

Except for 200 V / 22 kW and 400 V / 30 kW

-

Current response (ACR): 500Hz

-

Speed control accuracy: ±0.01%

200% of rated current for 10s (Note2)

(Overload begins from 80% continuous operation with a carrier frequency of 10kHz.)

-

Note2

-

Except for 200 V / 22 kW and 400 V / 30 kW

A single AC Drive can control an induction motor (open/closed loop control) and a synchronous motor (the optional PG interface card is required).

FRENIC-Lift AC Drives are available in a series with capacities ranging from 4.0 to 45kW for three-phase 400V model.

5.5 to 22kW for three-phase 200V model.

2.2kW for single-phase 200V model.

-

Applicable to the inputs by open collector/complementary output as a standard specification (Encoder power supply is switchable between +12V and +15V.)

-

Applicable to the inputs from the 5V line driver as an option

-

Applicable to Sin/Cos, Serial interface (EnDat2.1) and Parallel interface (4-bit gray code, UVM 3-bit code)

-

DC bus capacitor life: 7 years

-

Electrolytic capacitor life on the printed circuit boards: 7 years

-

Cooling fan life: 5 years

-

Life warning signal

-

Recording and display of cumulative operating time

-

Recording and display of cumulative operations

-

Safety standards

EN61800-5-1:2003,

EN954-1 Category3 -

Sink/source switchable

-

RS-485 communications (Modbus RTU) is adopted as standard equipment.

-

CAN Bus is adopted as standard equipment.

-

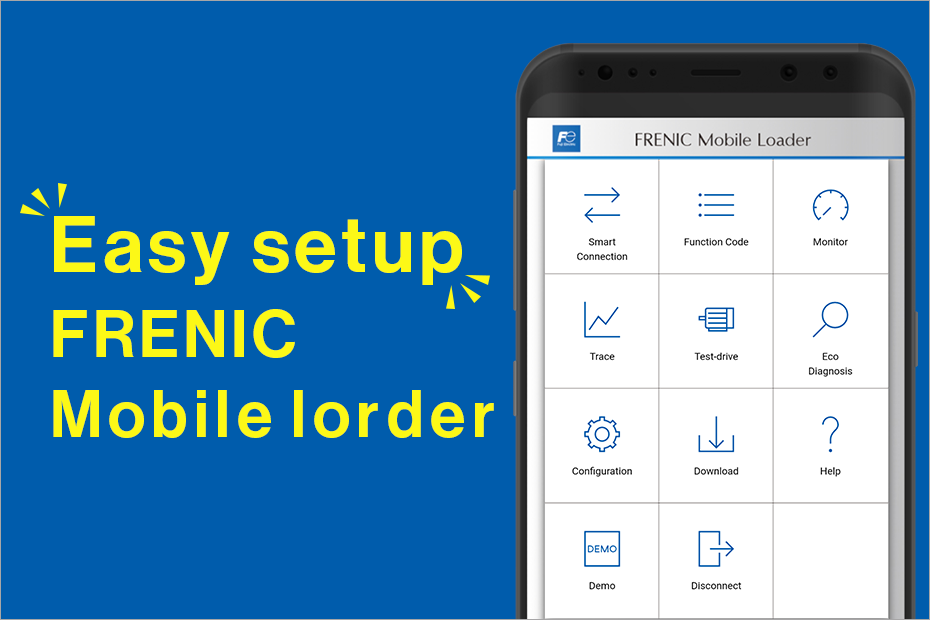

AC Drive support loader software is provided.

-

A multi-function keypad (with backlit LCD) makes it possible to copy or edit the function code data.

AC Drives (Low Voltage) Support

Download documents

Column

Understanding application, benefits, basic structure, case study, types, and Fuji Electric's inverters with this video.

December 27,2021

Understanding the basics: Differences between inverters and converters

January 20,2021

How and what does an inverter take control of? A brief explanation to grasp the basic structure.

January 20,2021

The fundamentals of inverters and their uses.

January 20,2021