FRENIC-VG

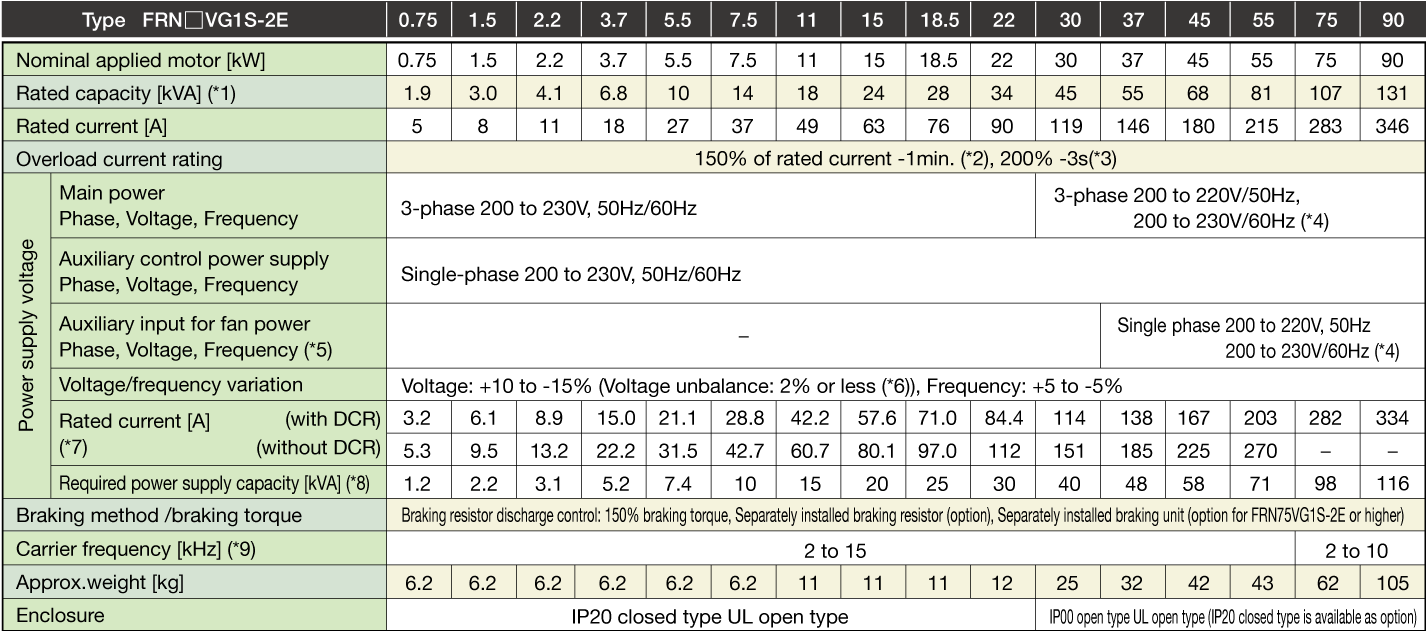

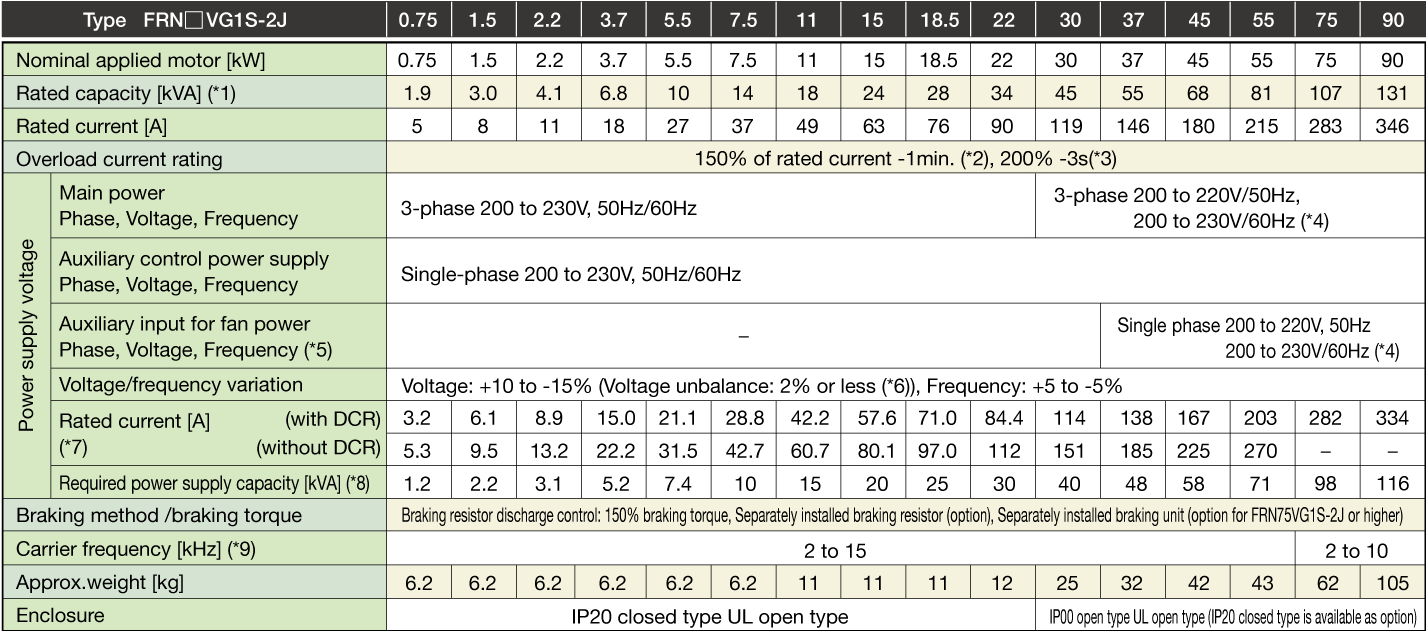

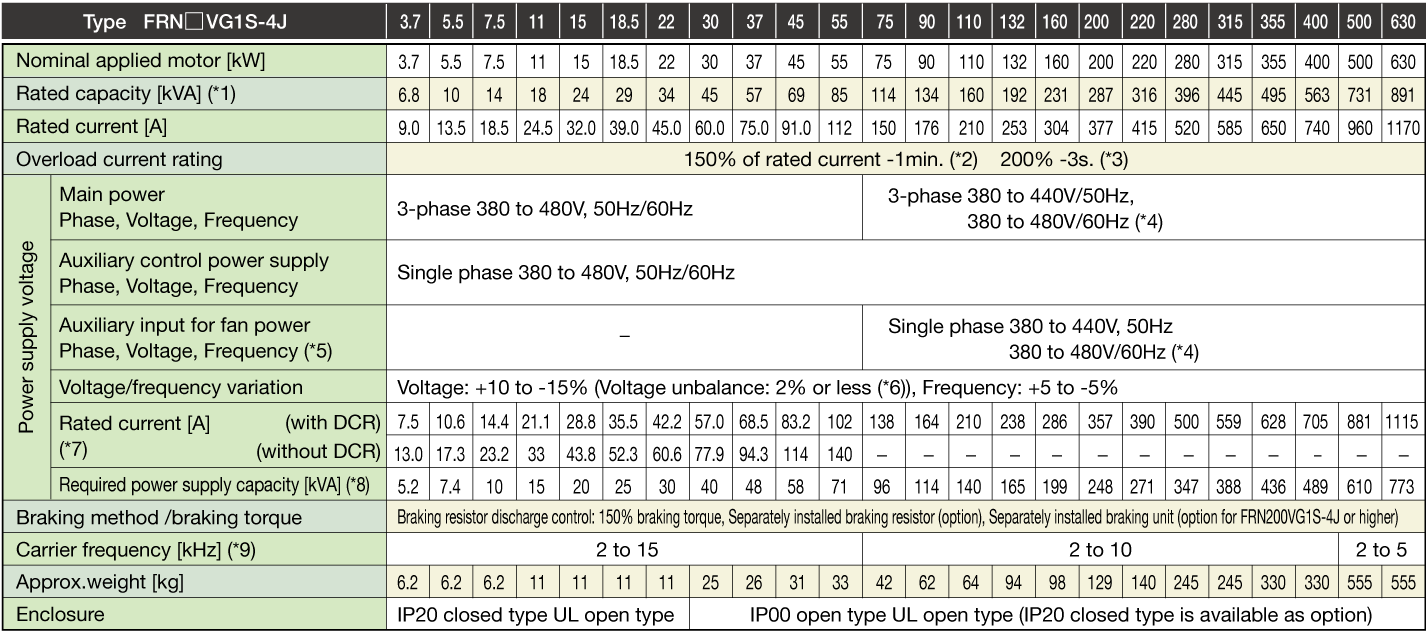

Specifications | Unit Type HD Specifications for Heavy Overload

-

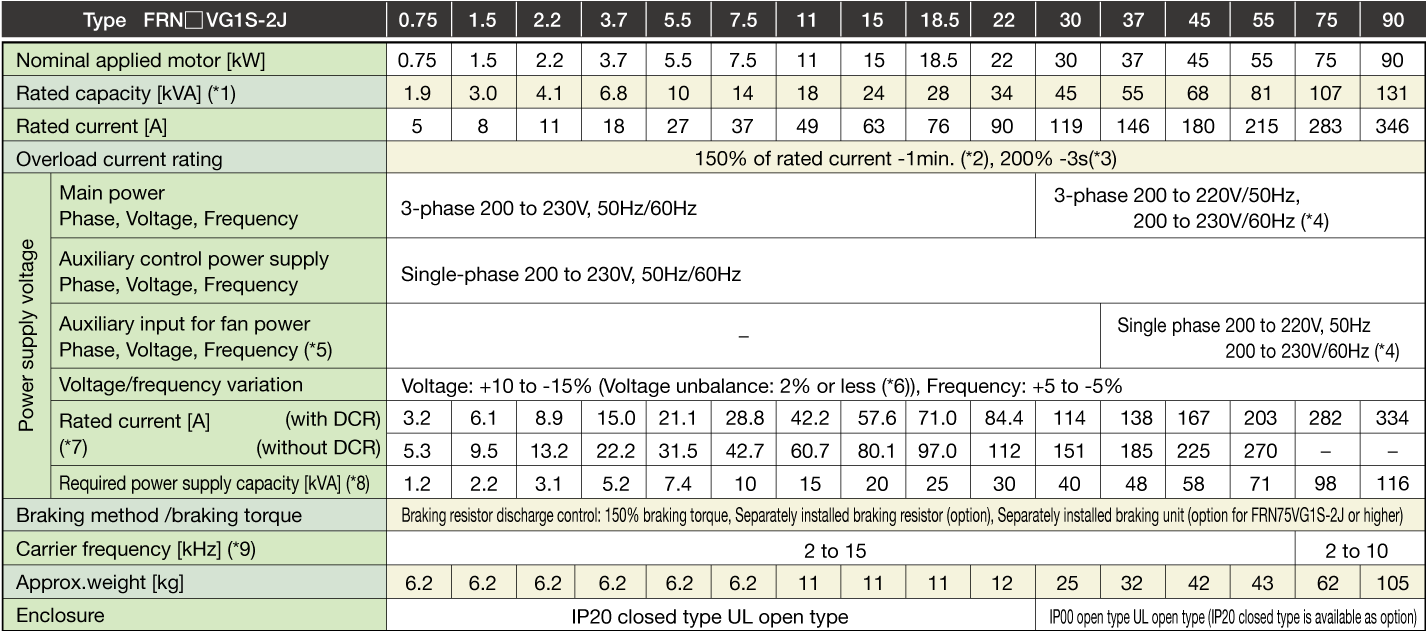

Unit Type HD Specifications for Heavy Overload

Three-phase 200V series

Three-phase 400V series

-

Note 1

-

The specification above are established when the function code F80 = 0 (HD specification) is applied.

The rated output voltage is 220V for 200V series and 440V for 400V series.

-

Note 2

-

When using a DC reactor, refer to the following.

When the inverter output frequency converter value is 10Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient

temperature.

-

・ Type FRN□VG1S-□J

-

55kW or below: provided as option, 75kW or above: provided as standard.

-

Note3

-

When the inverter output frequency converter value is 5Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient temperature.

-

Note4

-

200V series: Make an individual order for 220 to 230V/50Hz.

400V series: The inverters with the power supply of 380 to 398V/50Hz and 380 to 430V/60Hz must be switched using a connector inside the inverter.

The output of the inverter with 380V may drop depending on situations. For details, refer to Chapter 10 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.

-

Note5

-

The auxiliary power input is used as an AC fan power input when combining the unit such as high power factor PWM converter with power regenerative function.(Generally not used.)

-

Note6

-

Voltage unbalance [%] = (Max. voltage [V] - Min. voltage [V]) / (Three-phase average voltage [V]) × 67

Use an AC reactor if the voltage unbalance exceeds 2%.

-

Note7

-

The value is calculated on assumption that the inverter is connected with a power supply capacity of 500kVA (or 10 times the inverter capacity if the inverter capacity exceeds 50kVA) and %X is 5%.

-

Note8

-

The values shown apply when a DC reactor is used.

If using a generator for the power source, it may burn out with high-frequency current from the inverter. Use a generator with 3 to 4 times the specified power supply capacity.

(When DC reactor not connected: approx. 4 times specified power supply capacity, when DC reactor connected: approx. 3 times specified power supply capacity)

-

Note9

-

The inverter may automatically reduce carrier frequency in accordance with ambient temperature or output current in order to protect itself.

If the carrier frequency auto reduction selection (H104: digit 100) is cancelled, the unit continuous rated current will drop depending on the carrier frequency setting, and therefore caution is advised.

(For details, refer to Chapter 2 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.)

-

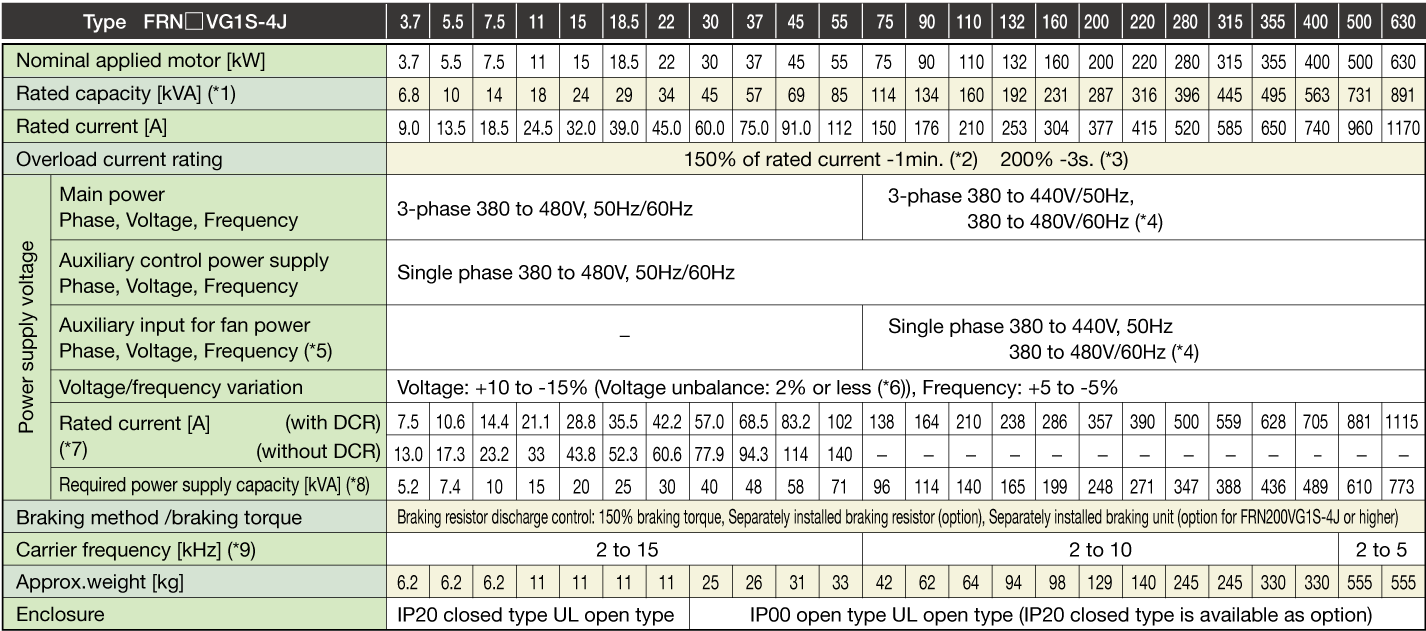

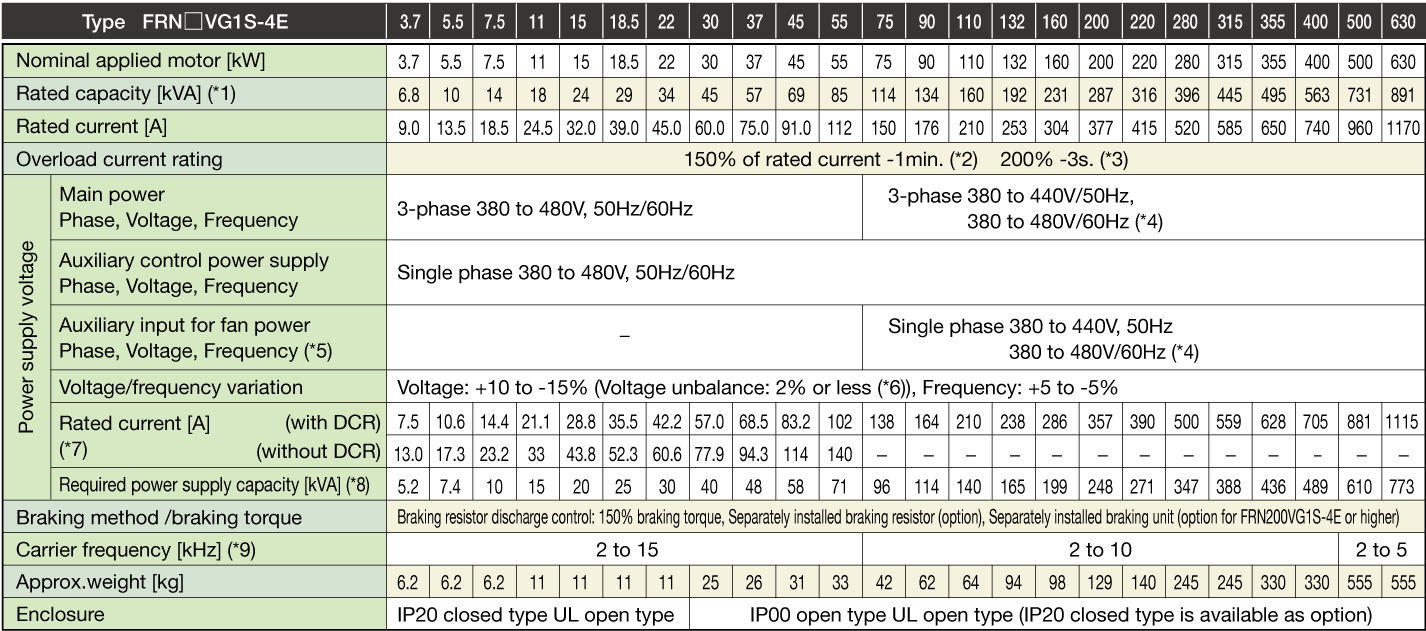

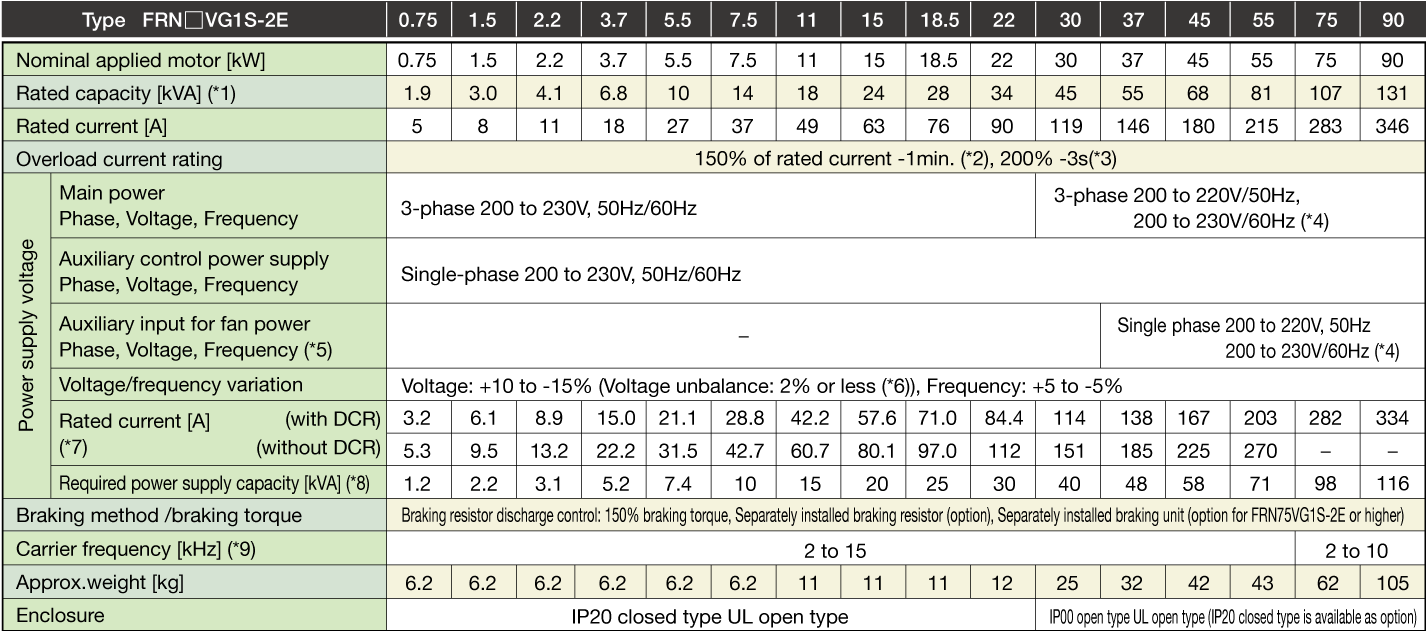

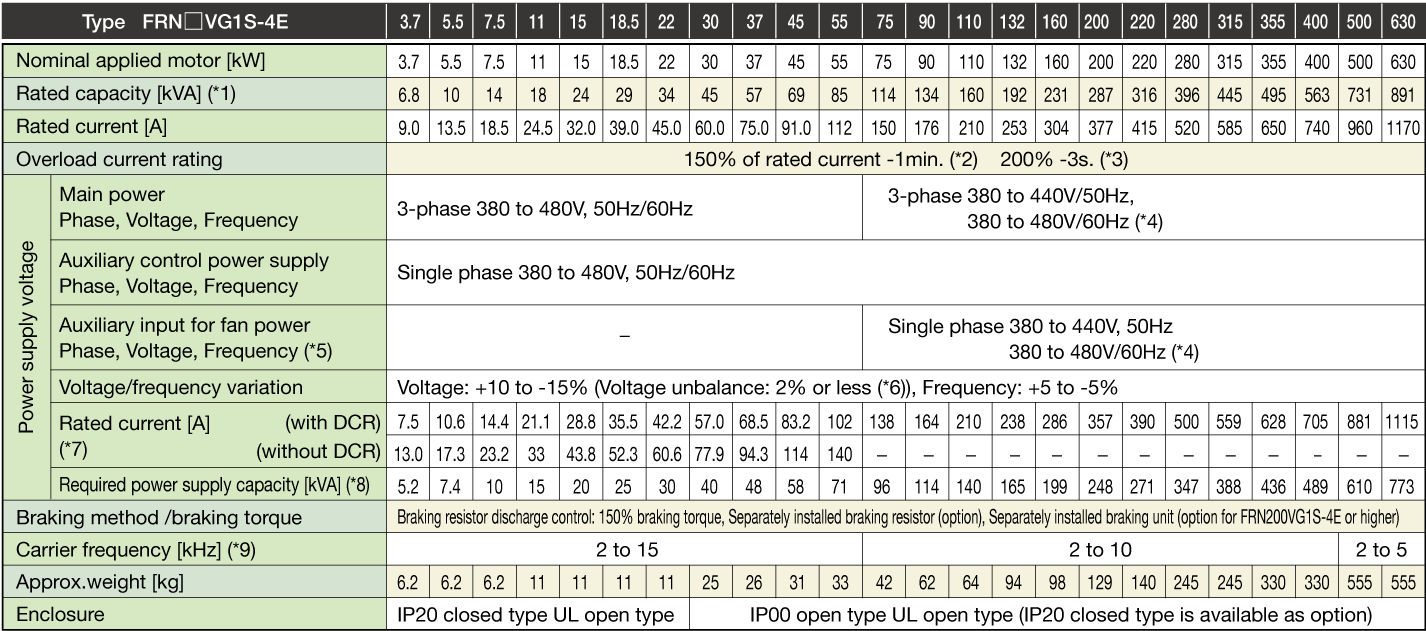

Unit Type HD Specifications for Heavy Overload

Three-phase 200V series

Three-phase 400V series

-

Note 1

-

The specification above are established when the function code F80 = 0 (HD specification) is applied.

The rated output voltage is 220V for 200V series and 440V for 400V series.

-

Note 2

-

When using a DC reactor, refer to the following.

When the inverter output frequency converter value is 10Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient

temperature.

-

・ Type FRN□VG1S-□E

-

All capacities are provided as option.

-

Note3

-

When the inverter output frequency converter value is 5Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient temperature.

-

Note4

-

200V series: Make an individual order for 220 to 230V/50Hz.

400V series: The inverters with the power supply of 380 to 398V/50Hz and 380 to 430V/60Hz must be switched using a connector inside the inverter.

The output of the inverter with 380V may drop depending on situations. For details, refer to Chapter 10 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.

-

Note5

-

The auxiliary power input is used as an AC fan power input when combining the unit such as high power factor PWM converter with power regenerative function.(Generally not used.)

-

Note6

-

Voltage unbalance [%] = (Max. voltage [V] - Min. voltage [V]) / (Three-phase average voltage [V]) × 67

Use an AC reactor if the voltage unbalance exceeds 2%.

-

Note7

-

The value is calculated on assumption that the inverter is connected with a power supply capacity of 500kVA (or 10 times the inverter capacity if the inverter capacity exceeds 50kVA) and %X is 5%.

-

Note8

-

The values shown apply when a DC reactor is used.

If using a generator for the power source, it may burn out with high-frequency current from the inverter. Use a generator with 3 to 4 times the specified power supply capacity.

(When DC reactor not connected: approx. 4 times specified power supply capacity, when DC reactor connected: approx. 3 times specified power supply capacity)

-

Note9

-

The inverter may automatically reduce carrier frequency in accordance with ambient temperature or output current in order to protect itself.

If the carrier frequency auto reduction selection (H104: digit 100) is cancelled, the unit continuous rated current will drop depending on the carrier frequency setting, and therefore caution is advised.

(For details, refer to Chapter 2 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.)

-

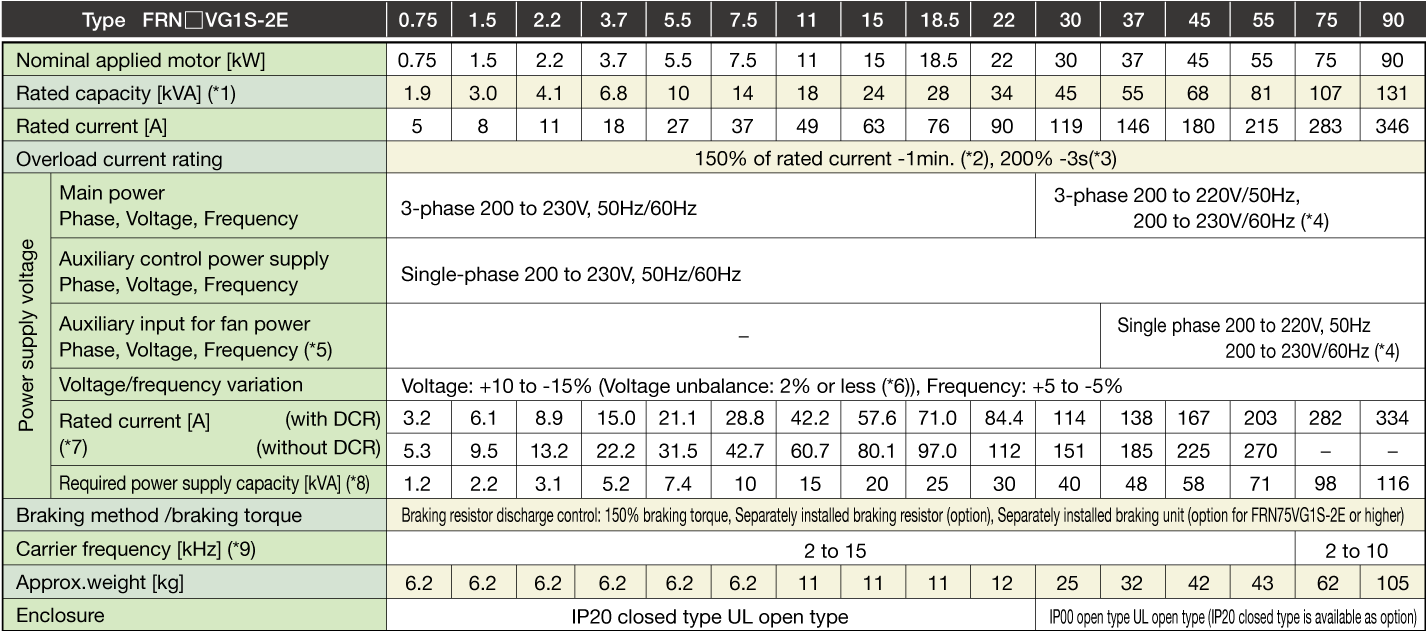

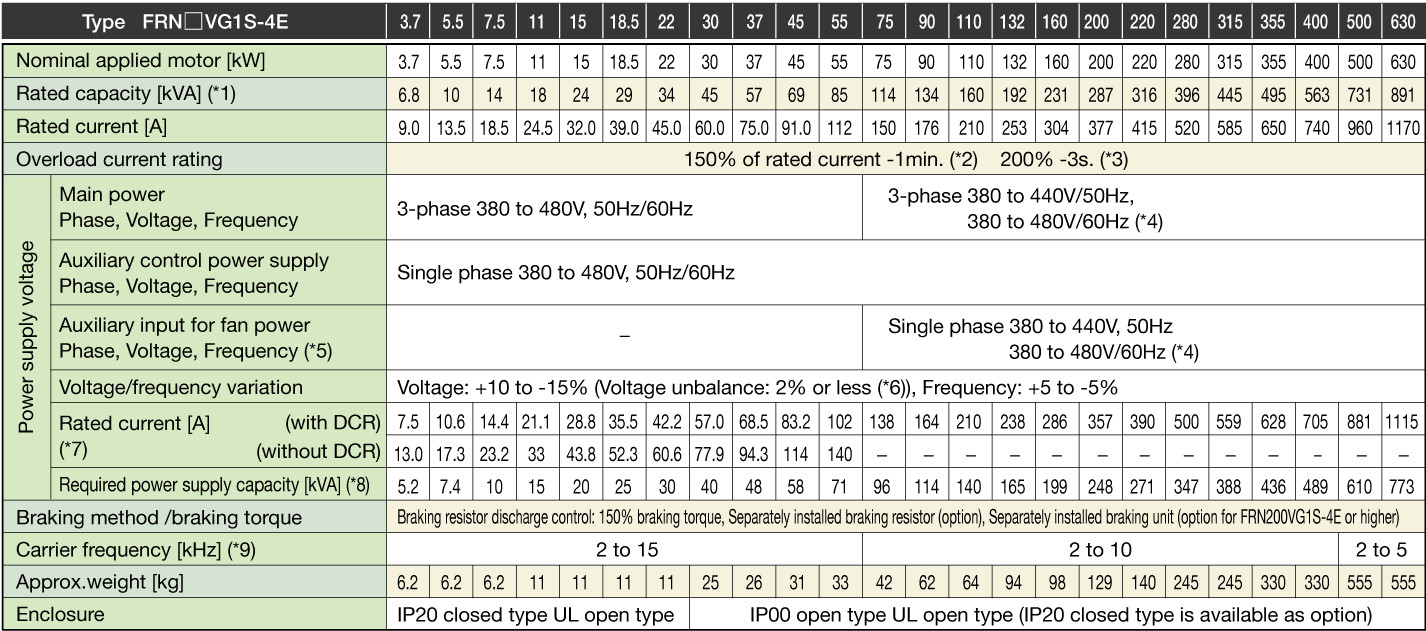

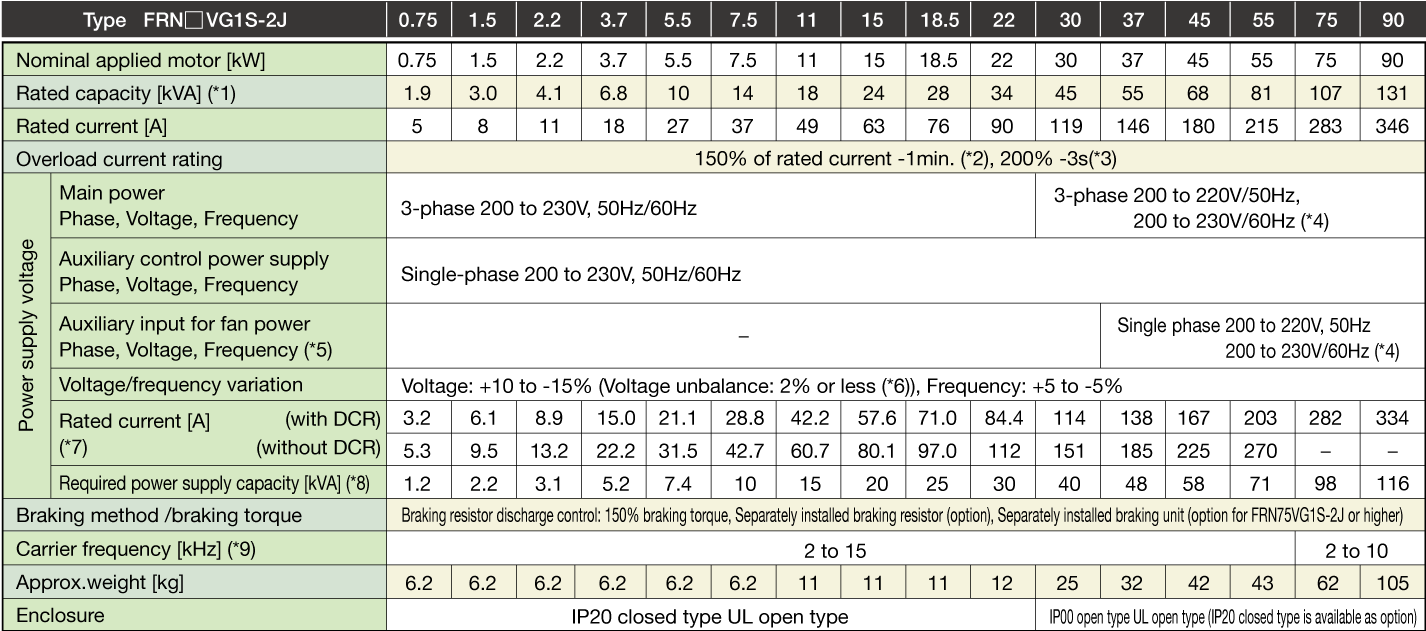

Unit Type HD Specifications for Heavy Overload

Three-phase 200V series

Three-phase 400V series

-

Note 1

-

The specification above are established when the function code F80 = 0 (HD specification) is applied.

The rated output voltage is 220V for 200V series and 440V for 400V series.

-

Note 2

-

When using a DC reactor, refer to the following.

When the inverter output frequency converter value is 10Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient

temperature.

-

・ Type FRN□VG1S-□E

-

All capacities are provided as option.

-

Note3

-

When the inverter output frequency converter value is 5Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient temperature.

-

Note4

-

200V series: Make an individual order for 220 to 230V/50Hz.

400V series: The inverters with the power supply of 380 to 398V/50Hz and 380 to 430V/60Hz must be switched using a connector inside the inverter.

The output of the inverter with 380V may drop depending on situations. For details, refer to Chapter 10 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.

-

Note5

-

The auxiliary power input is used as an AC fan power input when combining the unit such as high power factor PWM converter with power regenerative function.(Generally not used.)

-

Note6

-

Voltage unbalance [%] = (Max. voltage [V] - Min. voltage [V]) / (Three-phase average voltage [V]) × 67

Use an AC reactor if the voltage unbalance exceeds 2%.

-

Note7

-

The value is calculated on assumption that the inverter is connected with a power supply capacity of 500kVA (or 10 times the inverter capacity if the inverter capacity exceeds 50kVA) and %X is 5%.

-

Note8

-

The values shown apply when a DC reactor is used.

If using a generator for the power source, it may burn out with high-frequency current from the inverter. Use a generator with 3 to 4 times the specified power supply capacity.

(When DC reactor not connected: approx. 4 times specified power supply capacity, when DC reactor connected: approx. 3 times specified power supply capacity)

-

Note9

-

The inverter may automatically reduce carrier frequency in accordance with ambient temperature or output current in order to protect itself.

If the carrier frequency auto reduction selection (H104: digit 100) is cancelled, the unit continuous rated current will drop depending on the carrier frequency setting, and therefore caution is advised.

(For details, refer to Chapter 2 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.)

-

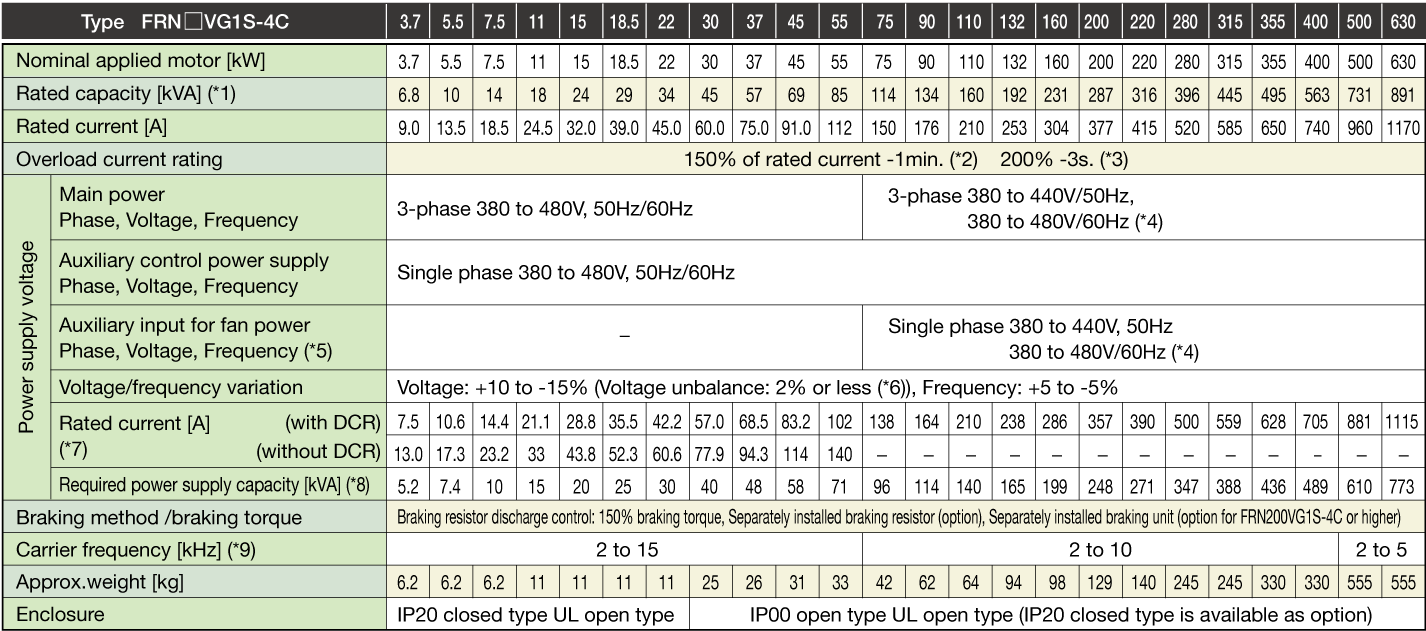

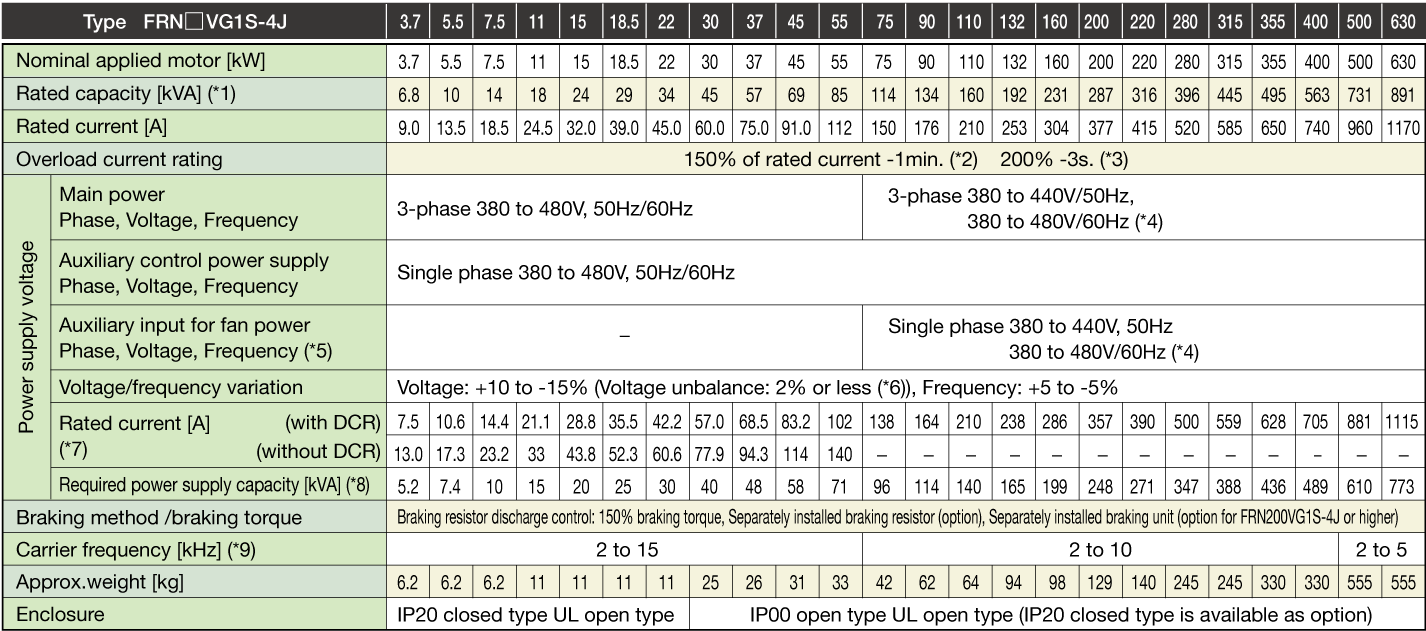

Unit Type HD Specifications for Heavy Overload

Three-phase 200V series

Three-phase 400V series

-

Note 1

-

The specification above are established when the function code F80 = 0 (HD specification) is applied.

The rated output voltage is 220V for 200V series and 440V for 400V series.

-

Note 2

-

When using a DC reactor, refer to the following.

When the inverter output frequency converter value is 10Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient

temperature.

-

・ Type FRN□VG1S-□C

-

All capacities are provided as option.

-

Note3

-

When the inverter output frequency converter value is 5Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient temperature.

-

Note4

-

200V series: Make an individual order for 220 to 230V/50Hz.

400V series: The inverters with the power supply of 380 to 398V/50Hz and 380 to 430V/60Hz must be switched using a connector inside the inverter.

The output of the inverter with 380V may drop depending on situations. For details, refer to Chapter 10 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.

-

Note5

-

The auxiliary power input is used as an AC fan power input when combining the unit such as high power factor PWM converter with power regenerative function.(Generally not used.)

-

Note6

-

Voltage unbalance [%] = (Max. voltage [V] - Min. voltage [V]) / (Three-phase average voltage [V]) × 67

Use an AC reactor if the voltage unbalance exceeds 2%.

-

Note7

-

The value is calculated on assumption that the inverter is connected with a power supply capacity of 500kVA (or 10 times the inverter capacity if the inverter capacity exceeds 50kVA) and %X is 5%.

-

Note8

-

The values shown apply when a DC reactor is used.

If using a generator for the power source, it may burn out with high-frequency current from the inverter. Use a generator with 3 to 4 times the specified power supply capacity.

(When DC reactor not connected: approx. 4 times specified power supply capacity, when DC reactor connected: approx. 3 times specified power supply capacity)

-

Note9

-

The inverter may automatically reduce carrier frequency in accordance with ambient temperature or output current in order to protect itself.

If the carrier frequency auto reduction selection (H104: digit 100) is cancelled, the unit continuous rated current will drop depending on the carrier frequency setting, and therefore caution is advised.

(For details, refer to Chapter 2 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.)

-

Unit Type HD Specifications for Heavy Overload

Three-phase 200V series

Three-phase 400V series

-

Note 1

-

The specification above are established when the function code F80 = 0 (HD specification) is applied.

The rated output voltage is 220V for 200V series and 440V for 400V series.

-

Note 2

-

When using a DC reactor, refer to the following.

When the inverter output frequency converter value is 10Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient

temperature.

-

・ Type FRN□VG1S-□E

-

All capacities are provided as option.

-

Note3

-

When the inverter output frequency converter value is 5Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient temperature.

-

Note4

-

200V series: Make an individual order for 220 to 230V/50Hz.

400V series: The inverters with the power supply of 380 to 398V/50Hz and 380 to 430V/60Hz must be switched using a connector inside the inverter.

The output of the inverter with 380V may drop depending on situations. For details, refer to Chapter 10 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.

-

Note5

-

The auxiliary power input is used as an AC fan power input when combining the unit such as high power factor PWM converter with power regenerative function.(Generally not used.)

-

Note6

-

Voltage unbalance [%] = (Max. voltage [V] - Min. voltage [V]) / (Three-phase average voltage [V]) × 67

Use an AC reactor if the voltage unbalance exceeds 2%.

-

Note7

-

The value is calculated on assumption that the inverter is connected with a power supply capacity of 500kVA (or 10 times the inverter capacity if the inverter capacity exceeds 50kVA) and %X is 5%.

-

Note8

-

The values shown apply when a DC reactor is used.

If using a generator for the power source, it may burn out with high-frequency current from the inverter. Use a generator with 3 to 4 times the specified power supply capacity.

(When DC reactor not connected: approx. 4 times specified power supply capacity, when DC reactor connected: approx. 3 times specified power supply capacity)

-

Note9

-

The inverter may automatically reduce carrier frequency in accordance with ambient temperature or output current in order to protect itself.

If the carrier frequency auto reduction selection (H104: digit 100) is cancelled, the unit continuous rated current will drop depending on the carrier frequency setting, and therefore caution is advised.

(For details, refer to Chapter 2 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.)

-

Unit Type HD Specifications for Heavy Overload

Three-phase 200V series

Three-phase 400V series

-

Note 1

-

The specification above are established when the function code F80 = 0 (HD specification) is applied.

The rated output voltage is 220V for 200V series and 440V for 400V series.

-

Note 2

-

When using a DC reactor, refer to the following.

When the inverter output frequency converter value is 10Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient

temperature.

-

・ Type FRN□VG1S-□J

-

55kW or below: provided as option, 75kW or above: provided as standard.

-

Note3

-

When the inverter output frequency converter value is 5Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient temperature.

-

Note4

-

200V series: Make an individual order for 220 to 230V/50Hz.

400V series: The inverters with the power supply of 380 to 398V/50Hz and 380 to 430V/60Hz must be switched using a connector inside the inverter.

The output of the inverter with 380V may drop depending on situations. For details, refer to Chapter 10 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.

-

Note5

-

The auxiliary power input is used as an AC fan power input when combining the unit such as high power factor PWM converter with power regenerative function.(Generally not used.)

-

Note6

-

Voltage unbalance [%] = (Max. voltage [V] - Min. voltage [V]) / (Three-phase average voltage [V]) × 67

Use an AC reactor if the voltage unbalance exceeds 2%.

-

Note7

-

The value is calculated on assumption that the inverter is connected with a power supply capacity of 500kVA (or 10 times the inverter capacity if the inverter capacity exceeds 50kVA) and %X is 5%.

-

Note8

-

The values shown apply when a DC reactor is used.

If using a generator for the power source, it may burn out with high-frequency current from the inverter. Use a generator with 3 to 4 times the specified power supply capacity.

(When DC reactor not connected: approx. 4 times specified power supply capacity, when DC reactor connected: approx. 3 times specified power supply capacity)

-

Note9

-

The inverter may automatically reduce carrier frequency in accordance with ambient temperature or output current in order to protect itself.

If the carrier frequency auto reduction selection (H104: digit 100) is cancelled, the unit continuous rated current will drop depending on the carrier frequency setting, and therefore caution is advised.

(For details, refer to Chapter 2 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.)

-

Unit Type HD Specifications for Heavy Overload

Three-phase 200V series

Three-phase 400V series

-

Note 1

-

The specification above are established when the function code F80 = 0 (HD specification) is applied.

The rated output voltage is 220V for 200V series and 440V for 400V series.

-

Note 2

-

When using a DC reactor, refer to the following.

When the inverter output frequency converter value is 10Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient

temperature.

-

・ Type FRN□VG1S-□J

-

55kW or below: provided as option, 75kW or above: provided as standard.

-

Note3

-

When the inverter output frequency converter value is 5Hz or less, the inverter may trip early due to overload depending on the conditions such as ambient temperature.

-

Note4

-

200V series: Make an individual order for 220 to 230V/50Hz.

400V series: The inverters with the power supply of 380 to 398V/50Hz and 380 to 430V/60Hz must be switched using a connector inside the inverter.

The output of the inverter with 380V may drop depending on situations. For details, refer to Chapter 10 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.

-

Note5

-

The auxiliary power input is used as an AC fan power input when combining the unit such as high power factor PWM converter with power regenerative function.(Generally not used.)

-

Note6

-

Voltage unbalance [%] = (Max. voltage [V] - Min. voltage [V]) / (Three-phase average voltage [V]) × 67

Use an AC reactor if the voltage unbalance exceeds 2%.

-

Note7

-

The value is calculated on assumption that the inverter is connected with a power supply capacity of 500kVA (or 10 times the inverter capacity if the inverter capacity exceeds 50kVA) and %X is 5%.

-

Note8

-

The values shown apply when a DC reactor is used.

If using a generator for the power source, it may burn out with high-frequency current from the inverter. Use a generator with 3 to 4 times the specified power supply capacity.

(When DC reactor not connected: approx. 4 times specified power supply capacity, when DC reactor connected: approx. 3 times specified power supply capacity)

-

Note9

-

The inverter may automatically reduce carrier frequency in accordance with ambient temperature or output current in order to protect itself.

If the carrier frequency auto reduction selection (H104: digit 100) is cancelled, the unit continuous rated current will drop depending on the carrier frequency setting, and therefore caution is advised.

(For details, refer to Chapter 2 in the FRENIC-VG User Manual "Unit Type, Function Code Edition" 24A7-□-0019.)

AC Drives (Low Voltage) Support

Download documents

Column

Understanding application, benefits, basic structure, case study, types, and Fuji Electric's inverters with this video.

December 27,2021

Understanding the basics: Differences between inverters and converters

January 20,2021

How and what does an inverter take control of? A brief explanation to grasp the basic structure.

January 20,2021

The fundamentals of inverters and their uses.

January 20,2021