FRENIC-VG

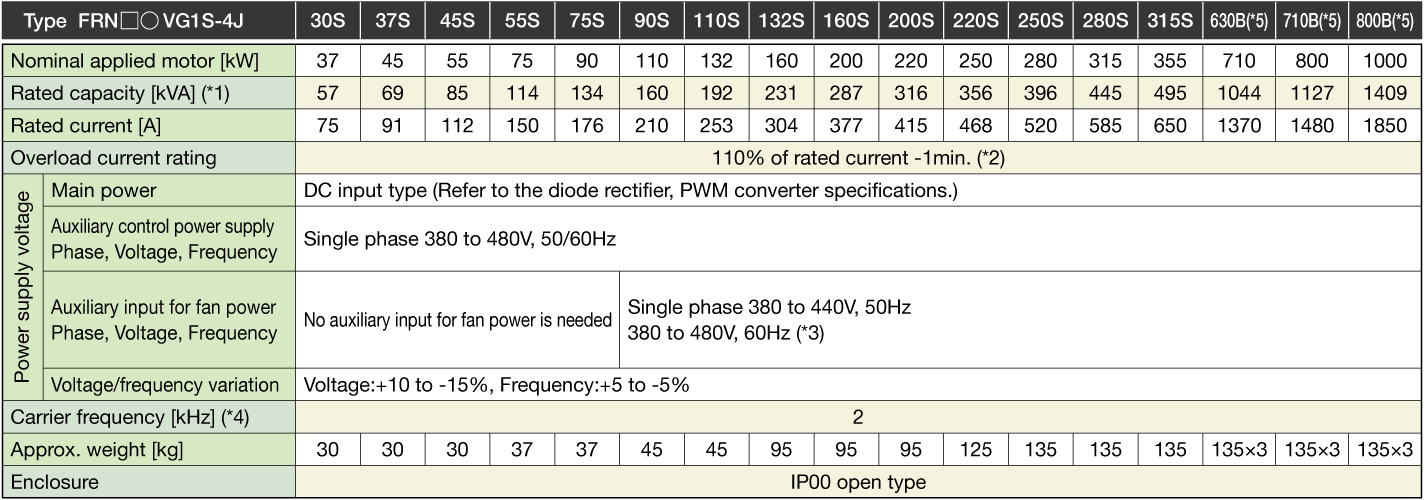

Specifications | Stack Type LD specifications for light overload

-

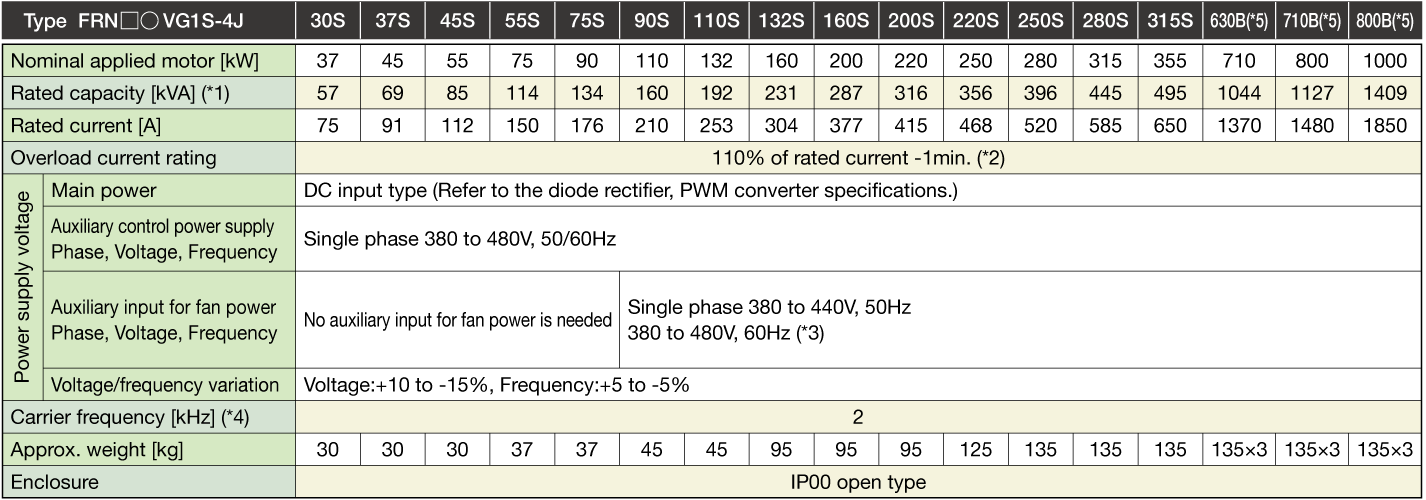

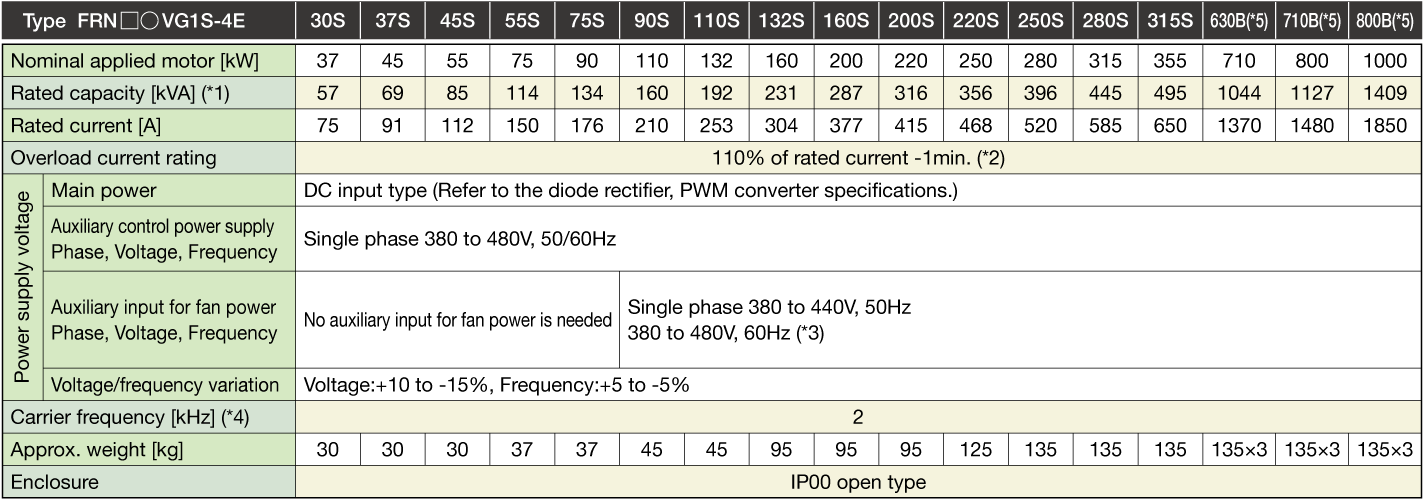

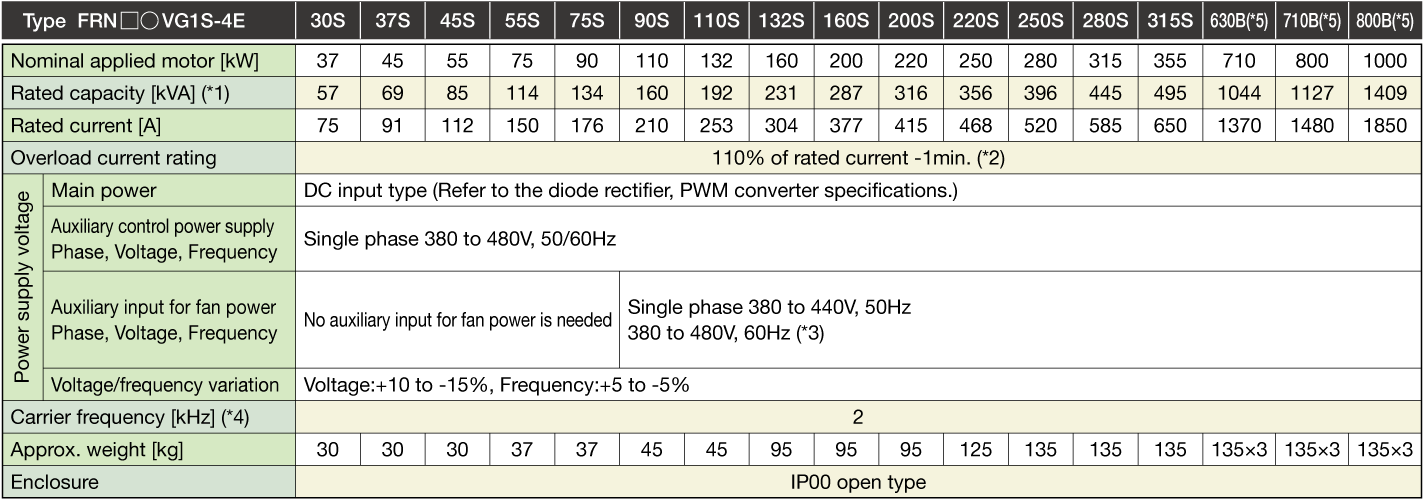

Stack Type LD specifications for light overload

Three-phase 400V

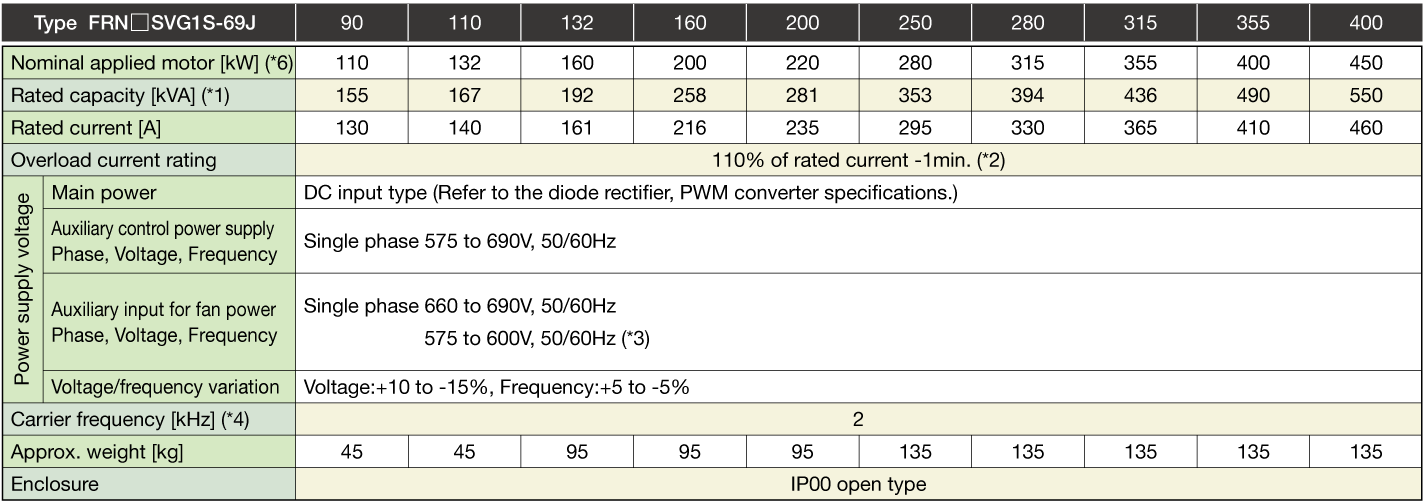

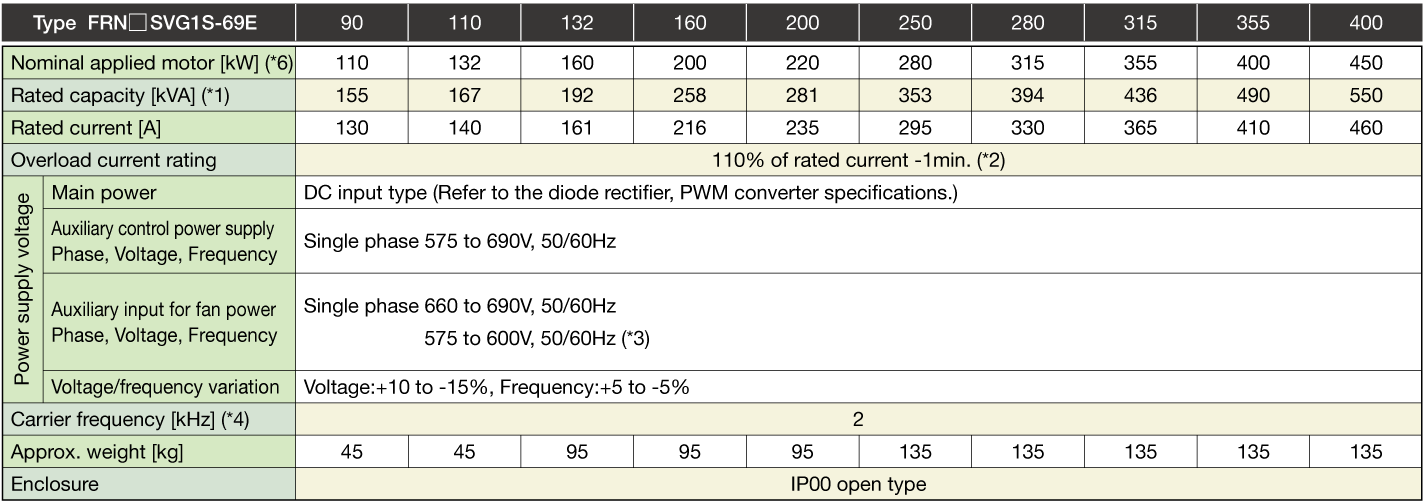

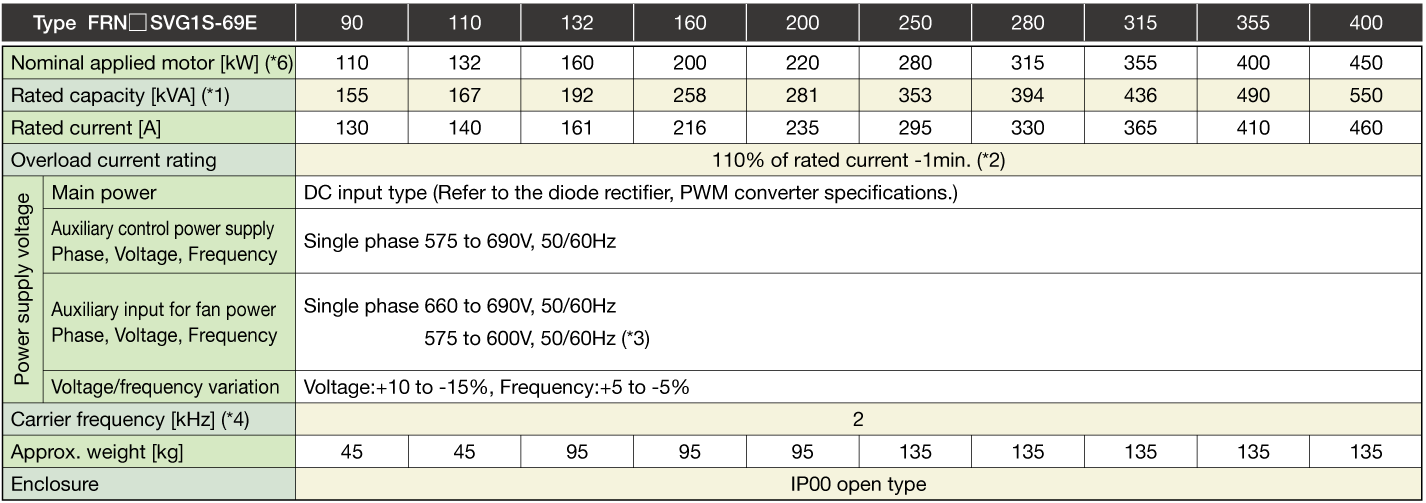

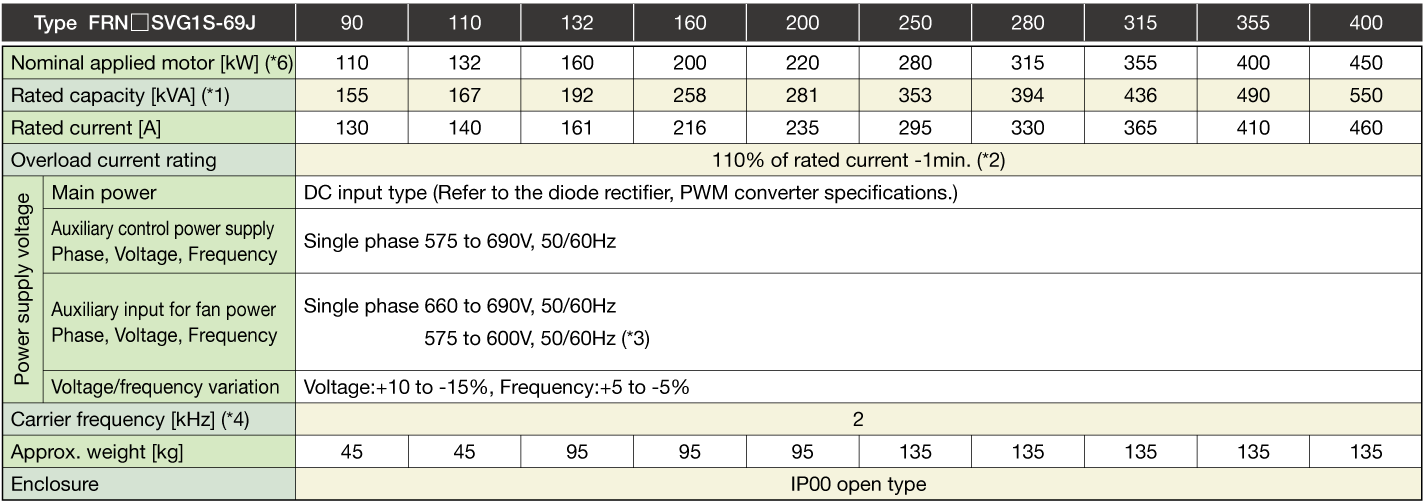

Three-phase 690V

-

Note1

-

The above specifications are for Function Code F80=1 (LD specification).

When the rated output voltage is 440 V (400V series) or 690 V (690V series).

-

Note2

-

When the converted inverter output frequency is less than 1Hz, the inverter may trip earlier in some ambient temperature conditions if the motor is overloaded.

-

Note3

-

400V series: When the power supply is 380 to 398 V at 50Hz, or 380 to 430 V at 60Hz, a connector inside the inverter must be reconnected accordingly.

690V series: When the power supply is 575 to 600 V at 50Hz/60Hz, a connector inside the inverter must be reconnected accordingly.

-

Note4

-

If running a synchronous motor at low carrier frequency, there is a risk of demagnetization due to permanent magnet overheating as a result of output current harmonics.

The carrier frequency is low (2kHz), and therefore the motor allowable carrier frequency must always be checked.

-

Note5

-

One set of the inverter consists of three stacks.

-

Note6

-

The nominal applied motor capacity is for a 690 V motor.

For motors of differing voltage specifications and detailed selections, select a capacity that will ensure that the inverter rated current is equal to or greater than the motor rated current.

-

Stack Type LD specifications for light overload

Three-phase 400V

Three-phase 690V

-

Note1

-

The above specifications are for Function Code F80=1 (LD specification).

When the rated output voltage is 440 V (400V series) or 690 V (690V series).

-

Note2

-

When the converted inverter output frequency is less than 1Hz, the inverter may trip earlier in some ambient temperature conditions if the motor is overloaded.

-

Note3

-

400V series: When the power supply is 380 to 398 V at 50Hz, or 380 to 430 V at 60Hz, a connector inside the inverter must be reconnected accordingly.

690V series: When the power supply is 575 to 600 V at 50Hz/60Hz, a connector inside the inverter must be reconnected accordingly.

-

Note4

-

If running a synchronous motor at low carrier frequency, there is a risk of demagnetization due to permanent magnet overheating as a result of output current harmonics.

The carrier frequency is low (2kHz), and therefore the motor allowable carrier frequency must always be checked.

-

Note5

-

One set of the inverter consists of three stacks.

-

Note6

-

The nominal applied motor capacity is for a 690 V motor.

For motors of differing voltage specifications and detailed selections, select a capacity that will ensure that the inverter rated current is equal to or greater than the motor rated current.

-

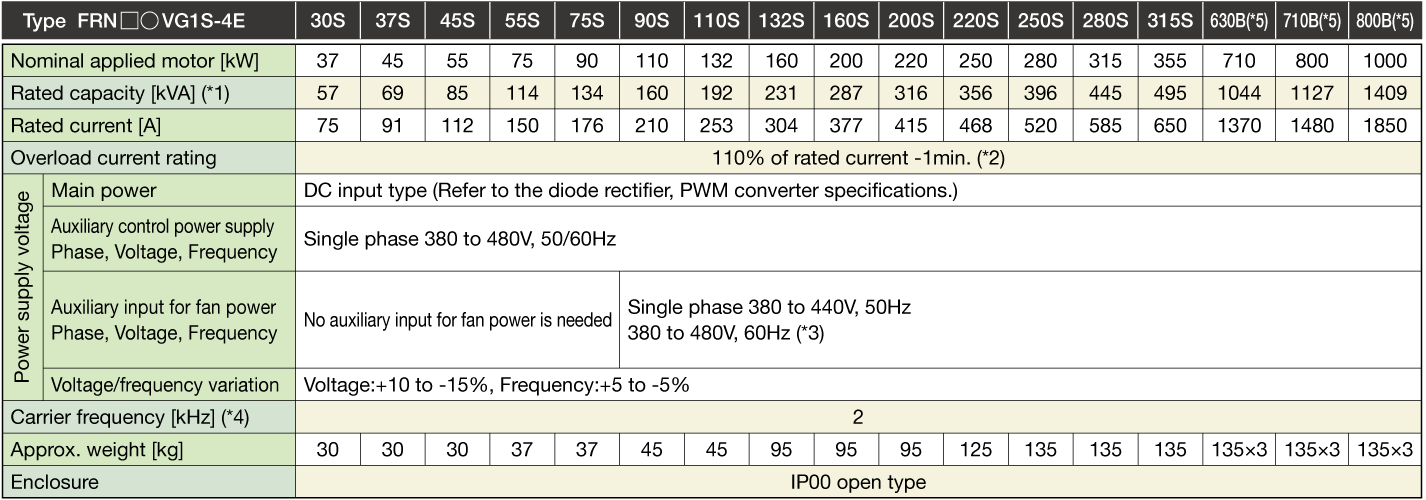

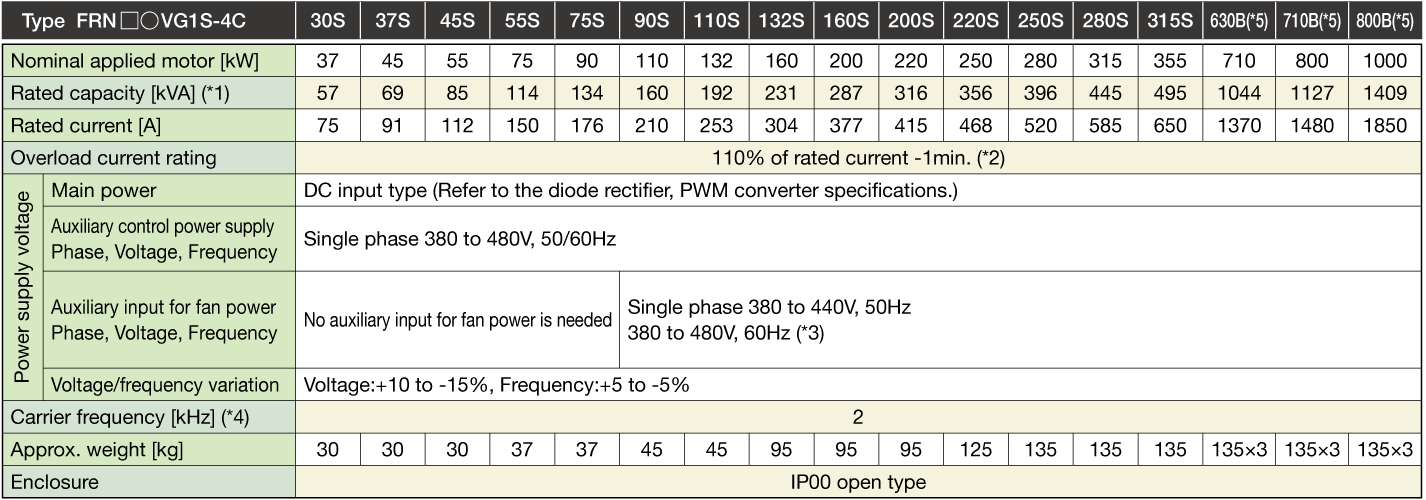

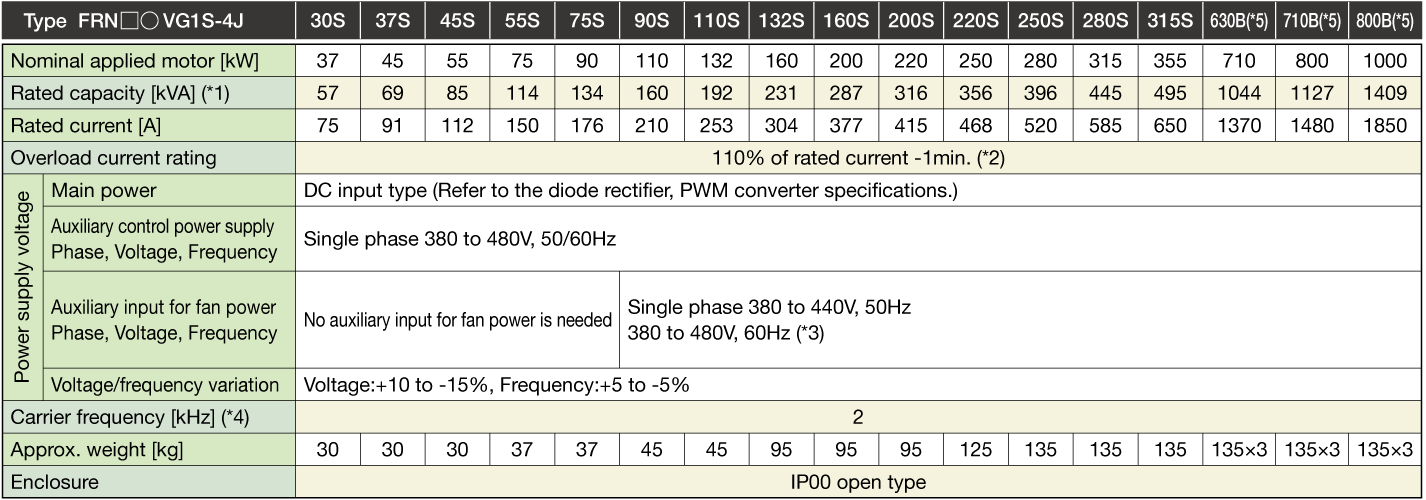

Stack Type LD specifications for light overload

Three-phase 400V

Three-phase 690V

-

Note1

-

The above specifications are for Function Code F80=1 (LD specification).

When the rated output voltage is 440 V (400V series) or 690 V (690V series).

-

Note2

-

When the converted inverter output frequency is less than 1Hz, the inverter may trip earlier in some ambient temperature conditions if the motor is overloaded.

-

Note3

-

400V series: When the power supply is 380 to 398 V at 50Hz, or 380 to 430 V at 60Hz, a connector inside the inverter must be reconnected accordingly.

690V series: When the power supply is 575 to 600 V at 50Hz/60Hz, a connector inside the inverter must be reconnected accordingly.

-

Note4

-

If running a synchronous motor at low carrier frequency, there is a risk of demagnetization due to permanent magnet overheating as a result of output current harmonics.

The carrier frequency is low (2kHz), and therefore the motor allowable carrier frequency must always be checked.

-

Note5

-

One set of the inverter consists of three stacks.

-

Note6

-

The nominal applied motor capacity is for a 690 V motor.

For motors of differing voltage specifications and detailed selections, select a capacity that will ensure that the inverter rated current is equal to or greater than the motor rated current.

-

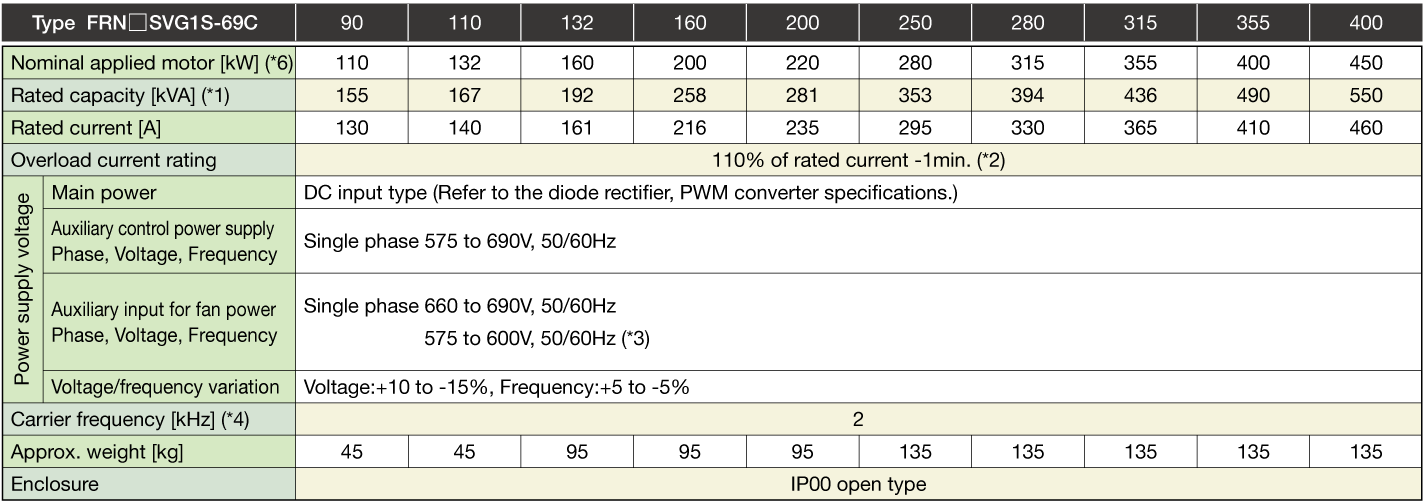

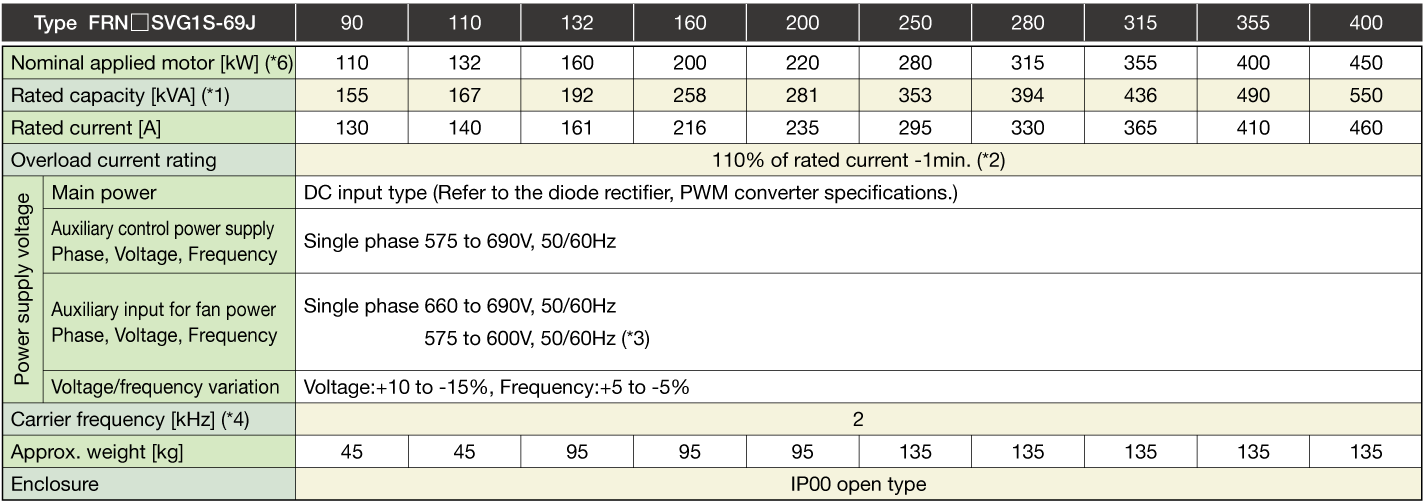

Stack Type LD specifications for light overload

Three-phase 400V

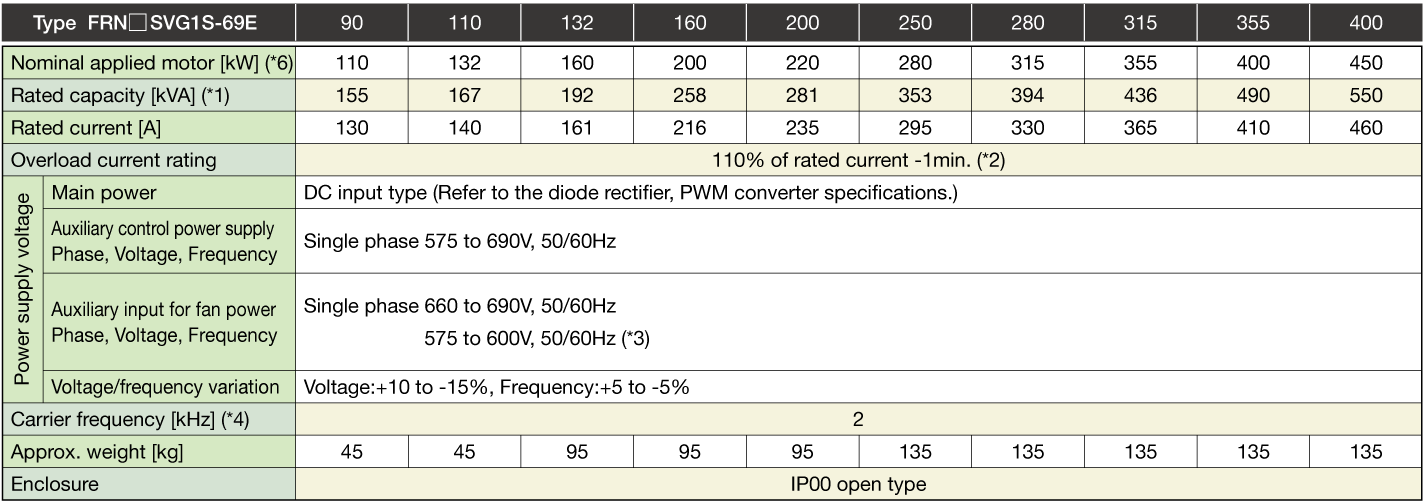

Three-phase 690V

-

Note1

-

The above specifications are for Function Code F80=1 (LD specification).

When the rated output voltage is 440 V (400V series) or 690 V (690V series).

-

Note2

-

When the converted inverter output frequency is less than 1Hz, the inverter may trip earlier in some ambient temperature conditions if the motor is overloaded.

-

Note3

-

400V series: When the power supply is 380 to 398 V at 50Hz, or 380 to 430 V at 60Hz, a connector inside the inverter must be reconnected accordingly.

690V series: When the power supply is 575 to 600 V at 50Hz/60Hz, a connector inside the inverter must be reconnected accordingly.

-

Note4

-

If running a synchronous motor at low carrier frequency, there is a risk of demagnetization due to permanent magnet overheating as a result of output current harmonics.

The carrier frequency is low (2kHz), and therefore the motor allowable carrier frequency must always be checked.

-

Note5

-

One set of the inverter consists of three stacks.

-

Note6

-

The nominal applied motor capacity is for a 690 V motor.

For motors of differing voltage specifications and detailed selections, select a capacity that will ensure that the inverter rated current is equal to or greater than the motor rated current.

-

Stack Type LD specifications for light overload

Three-phase 400V

Three-phase 690V

-

Note1

-

The above specifications are for Function Code F80=1 (LD specification).

When the rated output voltage is 440 V (400V series) or 690 V (690V series).

-

Note2

-

When the converted inverter output frequency is less than 1Hz, the inverter may trip earlier in some ambient temperature conditions if the motor is overloaded.

-

Note3

-

400V series: When the power supply is 380 to 398 V at 50Hz, or 380 to 430 V at 60Hz, a connector inside the inverter must be reconnected accordingly.

690V series: When the power supply is 575 to 600 V at 50Hz/60Hz, a connector inside the inverter must be reconnected accordingly.

-

Note4

-

If running a synchronous motor at low carrier frequency, there is a risk of demagnetization due to permanent magnet overheating as a result of output current harmonics.

The carrier frequency is low (2kHz), and therefore the motor allowable carrier frequency must always be checked.

-

Note5

-

One set of the inverter consists of three stacks.

-

Note6

-

The nominal applied motor capacity is for a 690 V motor.

For motors of differing voltage specifications and detailed selections, select a capacity that will ensure that the inverter rated current is equal to or greater than the motor rated current.

-

Stack Type LD specifications for light overload

Three-phase 400V

Three-phase 690V

-

Note1

-

The above specifications are for Function Code F80=1 (LD specification).

When the rated output voltage is 440 V (400V series) or 690 V (690V series).

-

Note2

-

When the converted inverter output frequency is less than 1Hz, the inverter may trip earlier in some ambient temperature conditions if the motor is overloaded.

-

Note3

-

400V series: When the power supply is 380 to 398 V at 50Hz, or 380 to 430 V at 60Hz, a connector inside the inverter must be reconnected accordingly.

690V series: When the power supply is 575 to 600 V at 50Hz/60Hz, a connector inside the inverter must be reconnected accordingly.

-

Note4

-

If running a synchronous motor at low carrier frequency, there is a risk of demagnetization due to permanent magnet overheating as a result of output current harmonics.

The carrier frequency is low (2kHz), and therefore the motor allowable carrier frequency must always be checked.

-

Note5

-

One set of the inverter consists of three stacks.

-

Note6

-

The nominal applied motor capacity is for a 690 V motor.

For motors of differing voltage specifications and detailed selections, select a capacity that will ensure that the inverter rated current is equal to or greater than the motor rated current.

-

Stack Type LD specifications for light overload

Three-phase 400V

Three-phase 690V

-

Note1

-

The above specifications are for Function Code F80=1 (LD specification).

When the rated output voltage is 440 V (400V series) or 690 V (690V series).

-

Note2

-

When the converted inverter output frequency is less than 1Hz, the inverter may trip earlier in some ambient temperature conditions if the motor is overloaded.

-

Note3

-

400V series: When the power supply is 380 to 398 V at 50Hz, or 380 to 430 V at 60Hz, a connector inside the inverter must be reconnected accordingly.

690V series: When the power supply is 575 to 600 V at 50Hz/60Hz, a connector inside the inverter must be reconnected accordingly.

-

Note4

-

If running a synchronous motor at low carrier frequency, there is a risk of demagnetization due to permanent magnet overheating as a result of output current harmonics.

The carrier frequency is low (2kHz), and therefore the motor allowable carrier frequency must always be checked.

-

Note5

-

One set of the inverter consists of three stacks.

-

Note6

-

The nominal applied motor capacity is for a 690 V motor.

For motors of differing voltage specifications and detailed selections, select a capacity that will ensure that the inverter rated current is equal to or greater than the motor rated current.