FRENIC-eRHR

Product Information

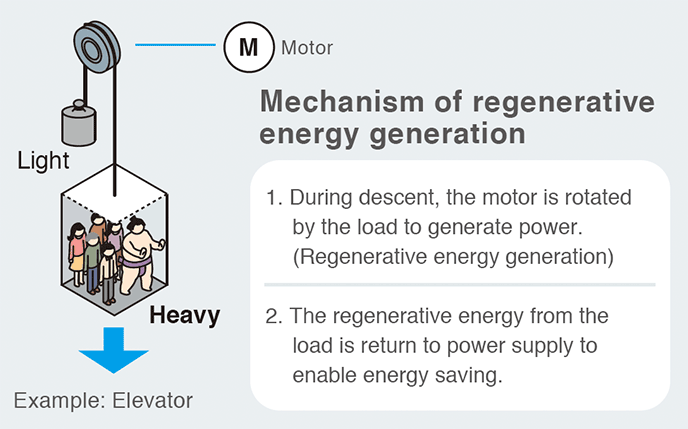

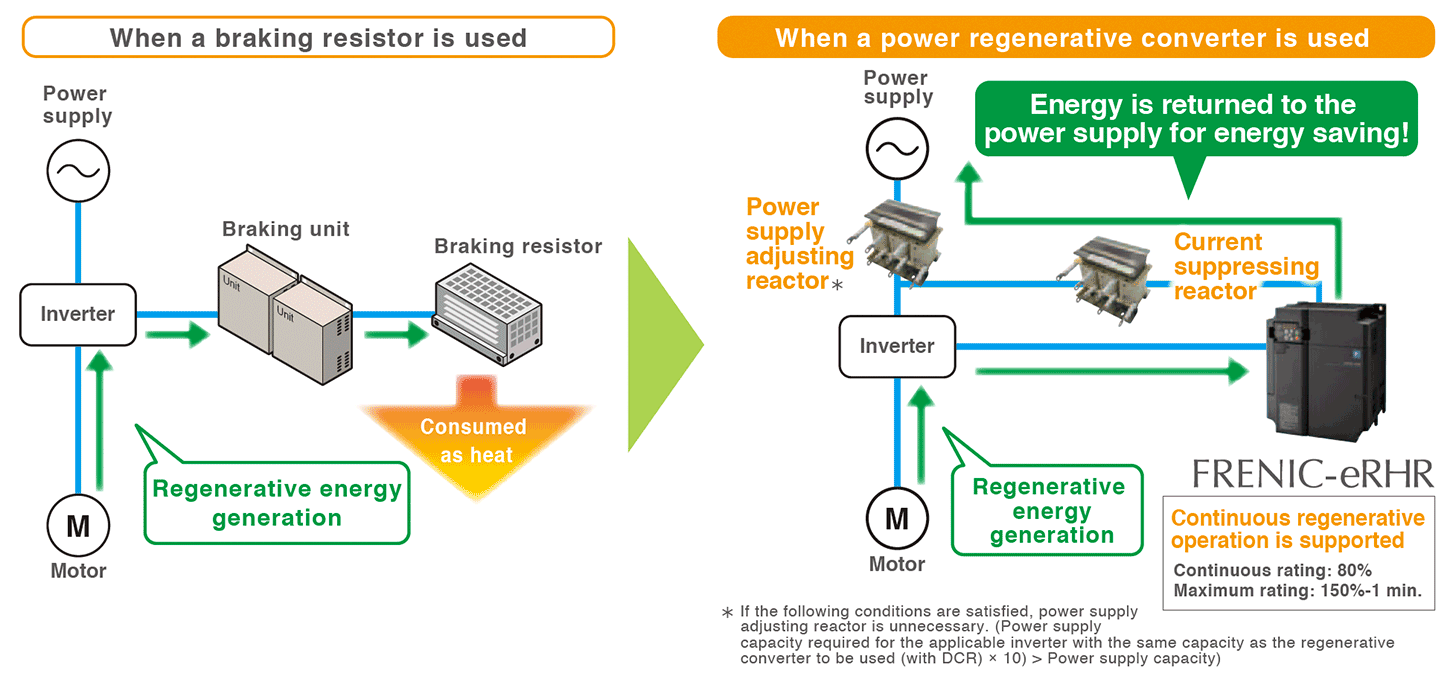

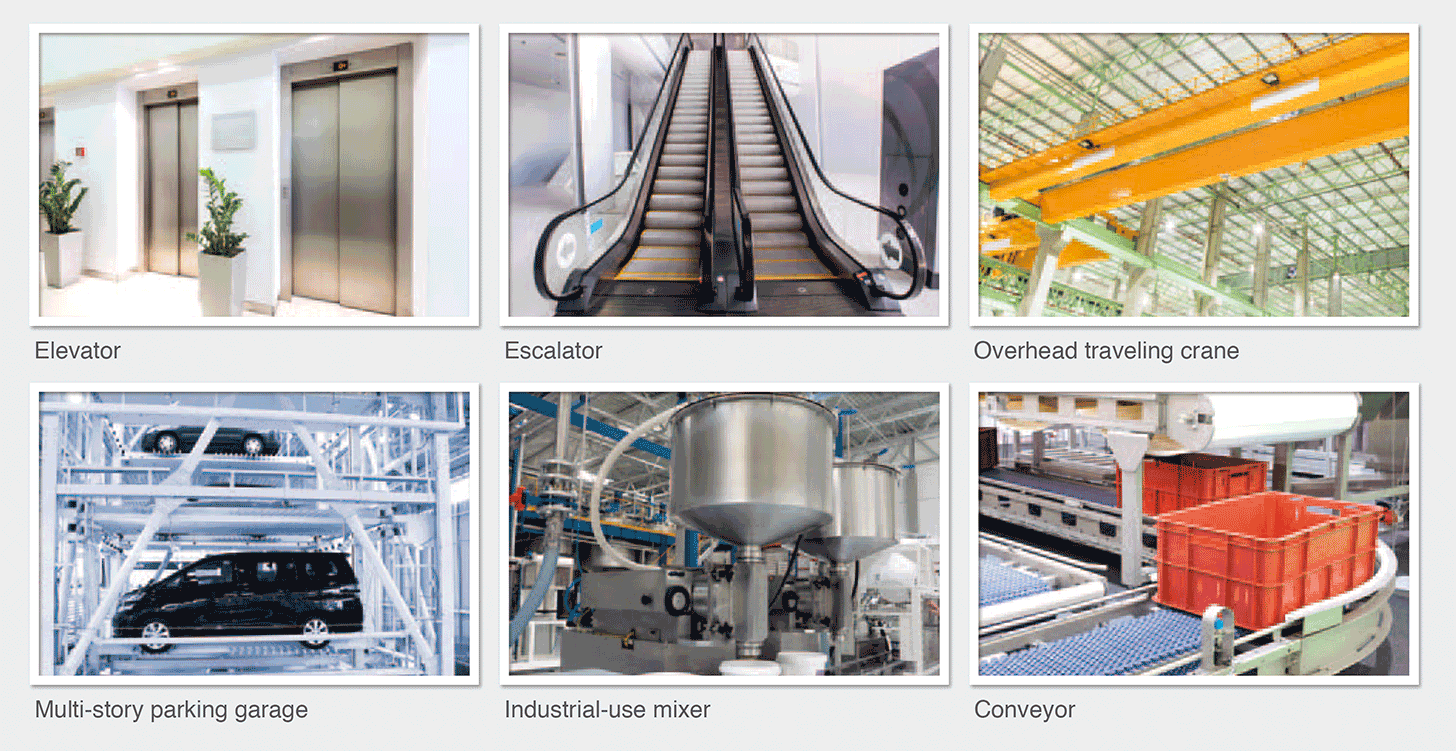

In a vertical transport system, conveyor, or equipment that is driven by an inverter, it is essential that regenerative energy produced by braking be processed. As a method to process this regenerative energy, it is common to use thermal conversion through the combination of a braking resistor and a braking unit, which has the following problems, however.

-

Energy is wasted because it is consumed as heat.

-

The size of the braking resistor becomes large depending on the load conditions, if continuous regenerative braking is required or if the instantaneous regenerative capacity is large.

To solve the above problems, we added this power regenerative converter series to the Fuji drive product lineup.

-

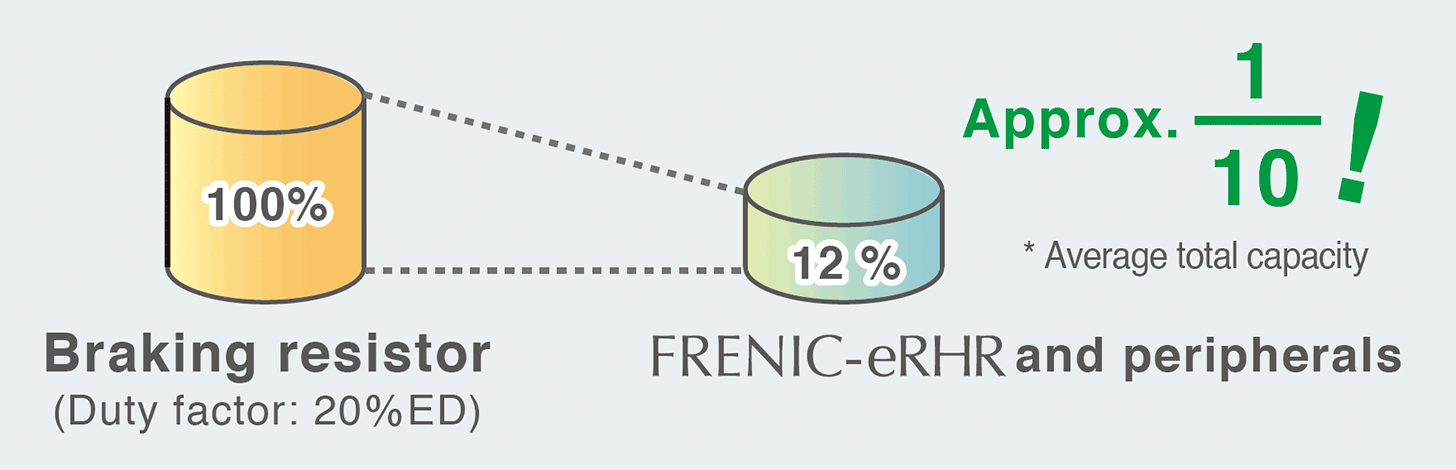

For peripherals, the FRENIC-eRHR requires only a current suppressing reactor and a power supply adjusting reactor.

The simple configuration not only reduces the introduction cost, but also enables energy saving through the power regeneration capability. -

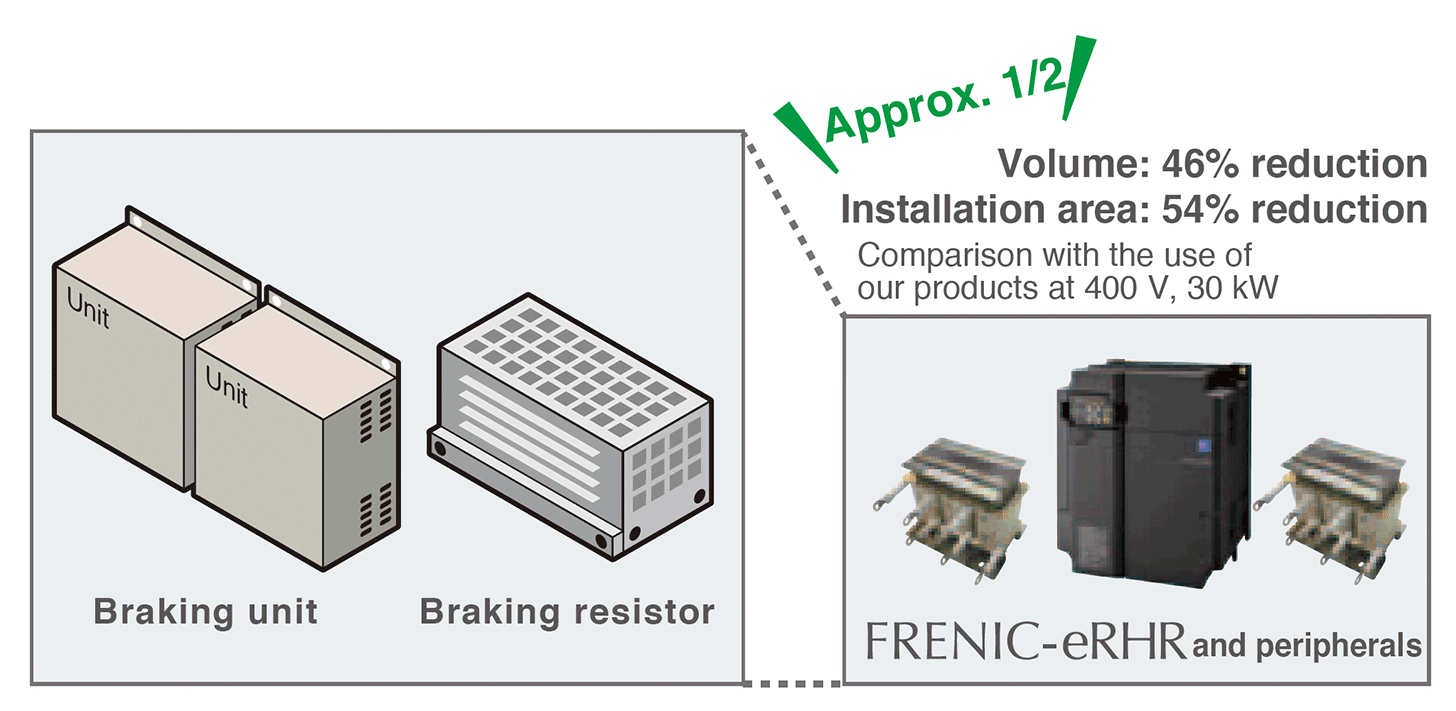

The FRENIC-eRHR saves the control panel space.

-

It enables the downsizing of the control panel compared with the combination of a braking resistor and a braking unit.

-

-

The FRENIC-eRHR no longer requires a braking resistor, which enables a compact control panel design due to significantly reduced heat generation. This also improves the freedom of the installation space because there is no need to worry about the clearance with the resistor.

-

The FRENIC-eRHR contributes to energy saving.

-

It returns the regenerative energy to the power supply, which contributes to energy saving compared with the combinationof a braking resistor and a braking unit.

-

-

The FRENIC-eRHR inherits the concept of our high-performance standard inverter FRENIC-Ace and, in addition to a similar appearance design, provides a variety of standard functions and a rich set of protective and maintenance functions.

-

The FRENIC-eRHR supports RS-485 communications as standard. It also has a touch panel that you can operate in the same way as that of the FRENIC-Ace.

For various components with a limited life, we offer 10 years of design life, which is the same as that of the Fuji inverter.

Note 1: This design life data represents calculated values, not guaranteed values.

This product is expected to comply with the EC Directive (CE Marking).

AC Drives (Low Voltage) Support

Download documents

Column

Understanding application, benefits, basic structure, case study, types, and Fuji Electric's inverters with this video.

December 27,2021

Understanding the basics: Differences between inverters and converters

January 20,2021

How and what does an inverter take control of? A brief explanation to grasp the basic structure.

January 20,2021

The fundamentals of inverters and their uses.

January 20,2021