FRENIC-VP (F2)

Product Information

Three pump control methods are available

-

Note1

-

Up to 2 units in the standard specification.

It is necessary to install an optional relay output card for circulating operation of 3 units.

Each inverter is connected by a communication link, and the system can be constructed without the need for a controller.

Also, no additional options are required and wiring can be reduced by using communication.

-

Temperature difference constant control and estimated terminal pressure control can be used by creating customized logic.

-

Users can create their own sequences.

-

Combinations of up to 200 steps are possible. A special software development environment is not required.

-

Digital logic circuits and analog arithmetic circuits can be configured using digital and analog input-output signals.

-

Logic settings can be protected by passwords.

-

Standard equipped with RS-485 port (terminal block) independent of the keypad

-

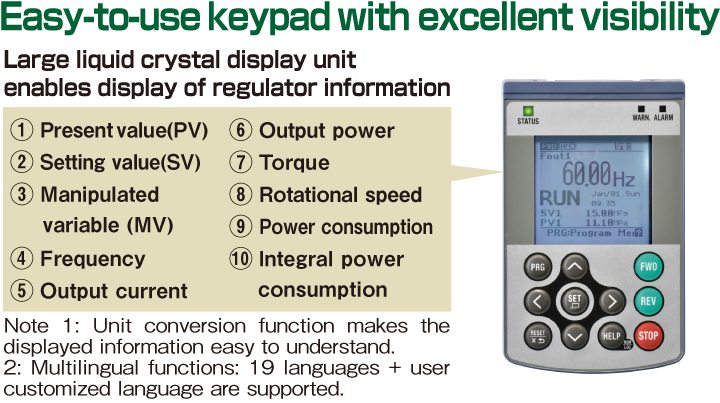

Optional keypad with USB port for communication with PC

-

Various communication interfaces can be supported with installation of an optional card

Input/output system: relay output, analog input/output, platinum resistance temperature detector (RTD) input (PT100)

Communication system: DeviceNet, PROFIBUS-DP, LonWorks -

Detachable interface panel is used

-

Sensorless synchronous motor control to meet further energy-saving requirements

-

Pick-up and regeneration avoidance operating functions

-

PID scaling functions (quantity setting)

The design life of the various parts with limited service life inside the inverter is 10 years. Lengthening of the maintenance cycle helps to reduce expenses.

-

Note

-

As the design life is a calculated value, it is not a guaranteed value.

This product conforms to the UL standards and CE directives.

AC Drives (Low Voltage) Support

Download documents

Column

Understanding application, benefits, basic structure, case study, types, and Fuji Electric's inverters with this video.

December 27,2021

Understanding the basics: Differences between inverters and converters

January 20,2021

How and what does an inverter take control of? A brief explanation to grasp the basic structure.

January 20,2021

The fundamentals of inverters and their uses.

January 20,2021