FRENIC-Mini (C2)

Product Information

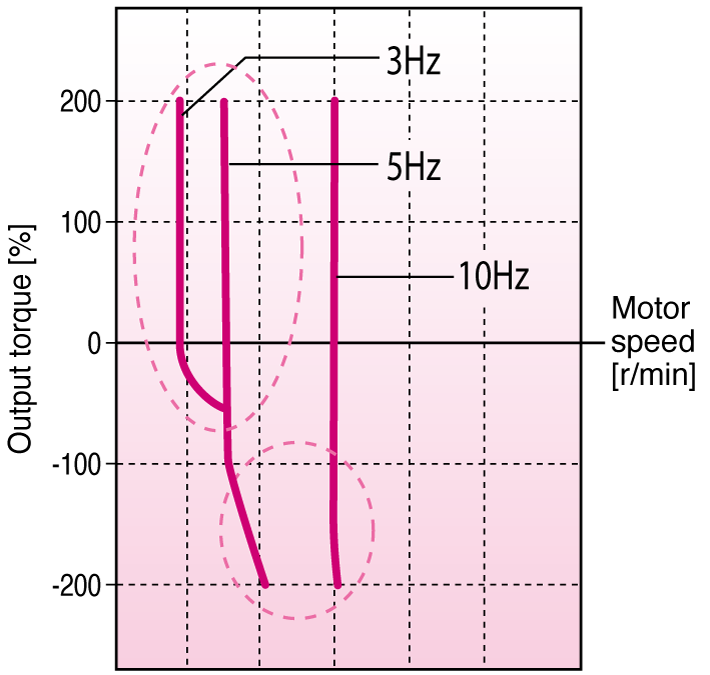

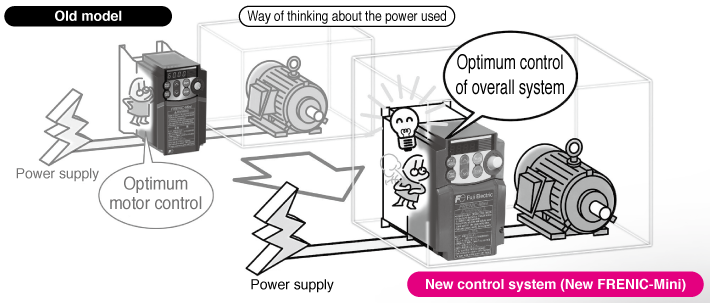

Fuji Electric original dynamic torque vector control system is known for its top-of-the line performance, delivering stabile torque output even at low speeds.

This feature has a wide range of applications, including conveyors and high-inertia loads that demand high starting torque.

The slip compensation controller works with voltage tuning for even more accurate speed control at low velocity. This reduces speed control variability and stabilizing creep speed for more accurate stopping in conveyors and similar equipment.

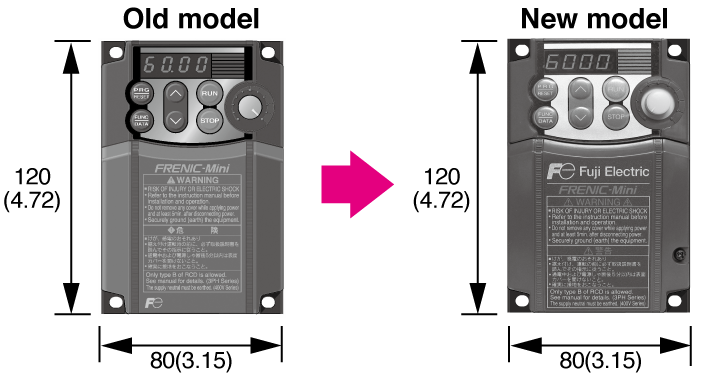

Advanced CPU processes data at twice the speed of our current model

Delivers all the usability of the C1. Provides volume of frequency and the same ease of operation as the curreßnt model.

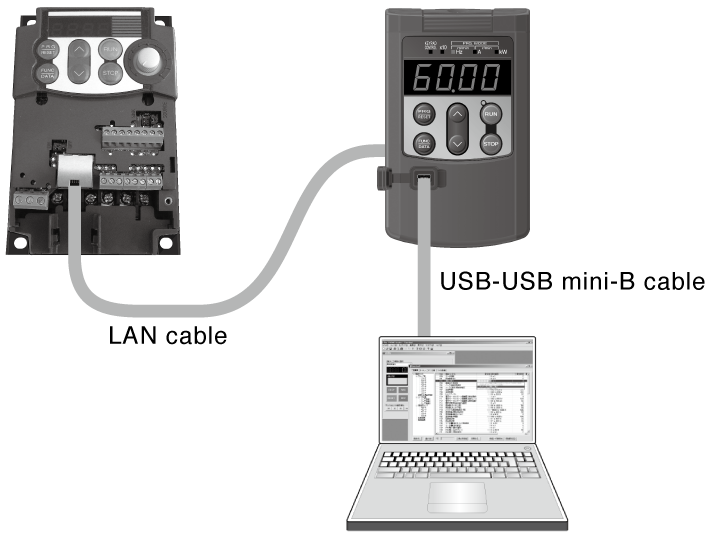

●USB Keypad(TP-E1U)

Optional USB keypad available. Enhanced PC loader software(FRENIC Loader) connectivity.

Motor tuning minimizes power loss

Permits motor operation while controlling temperature, pressure, and flow rate without the use of a temperature controller or other external device

The cooling fan can be switched off when the fan or pump is not running to reduce both noise and energy consumption

Use of sensorless synchronous motor control together with the motor can reduce energy consumption

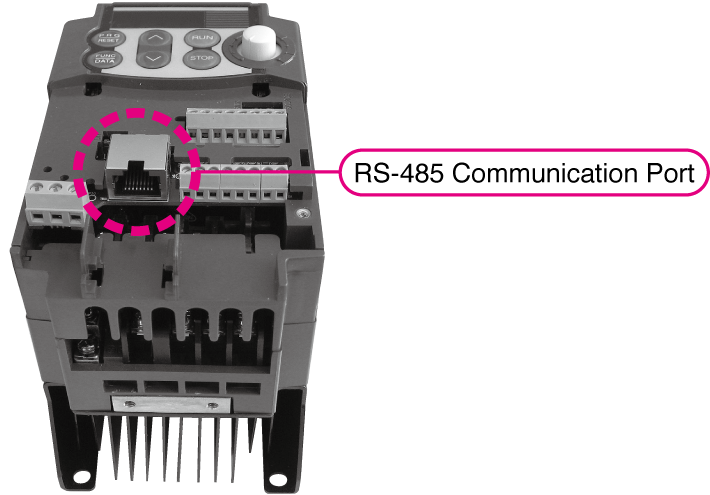

Communications can be controlled through the standard RS-485 communications port using the Modbus-RTU or Fuji Electric inverter protocol

V/F (non-linear 3 step)

Two motor parameter sets

Brake signal (brake release signal)

Rotational direction control (prevent forward/reverse movement)

EC Directives (CE making)

UL standard (cUL certification)

AC Drives (Low Voltage) Support

Download documents

Column

Understanding application, benefits, basic structure, case study, types, and Fuji Electric's inverters with this video.

December 27,2021

Understanding the basics: Differences between inverters and converters

January 20,2021

How and what does an inverter take control of? A brief explanation to grasp the basic structure.

January 20,2021

The fundamentals of inverters and their uses.

January 20,2021