IR Information

Environment Cross-Functional Strategy Supporting Business Growth Fuji Electric Report 2025

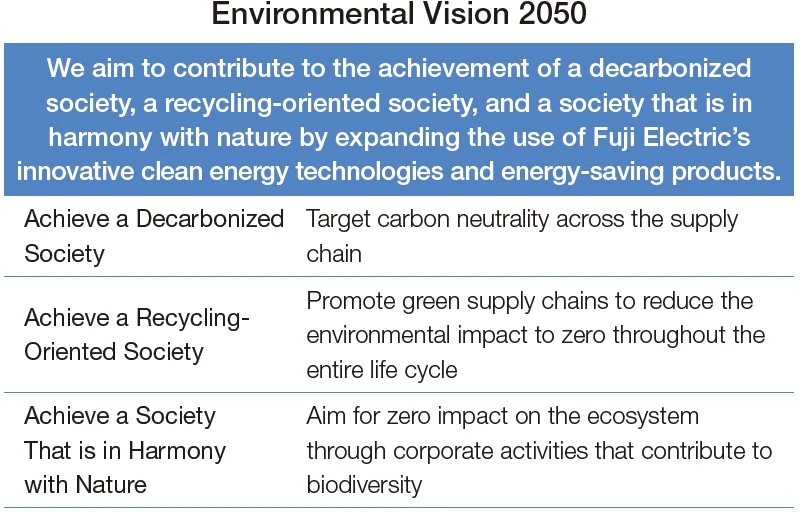

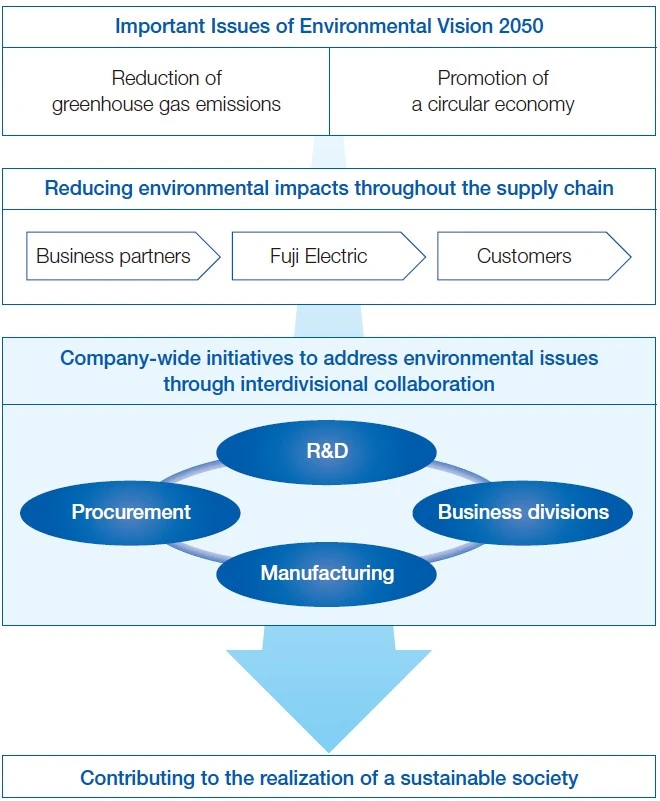

Through our initiatives toward Environmental Vision 2050, we will promote decarbonization and the transition to a circular economy, and contribute to the creation of a sustainable society.

Managing Executive Officer

Corporate General Manager, Production & Procurement Group

Takashi Obinata

In recent years, climate change has had a variety of impacts at global scale. The frequent occurrence of natural disasters such as torrential rains and heat waves as well as their impacts on ecosystems have become a threat that cannot be overlooked in nature and the social economy surrounding us. Furthermore, as a result of past mass consumption and mass disposal activities, a global environmental crisis is progressing, including the loss of biodiversity, pollution, and resource depletion. To address these problems, it is necessary to accelerate initiatives for decarbonization and for the transition to a circular economy, and the role that we as a company must play is becoming increasingly important.

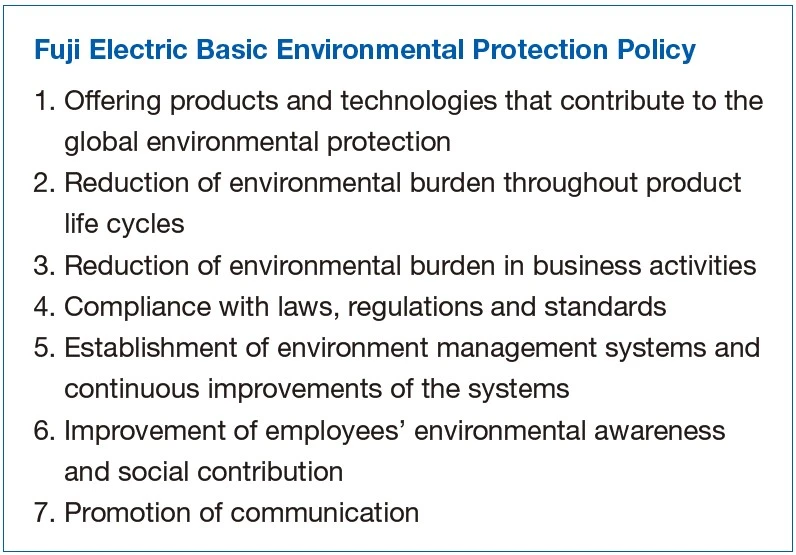

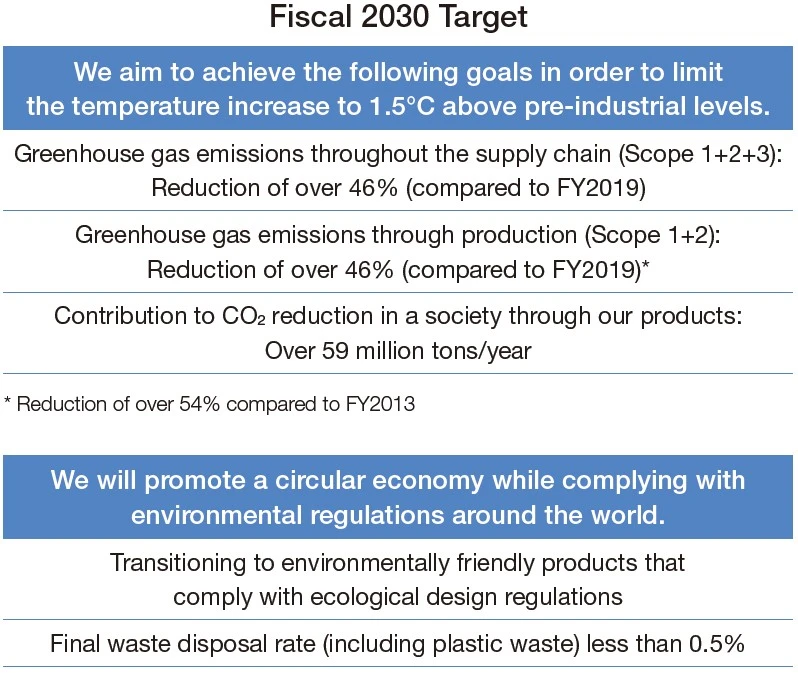

Under the Fuji Electric Basic Environmental Protection Policy, we have positioned global environmental protection as an important issue for management, and we formulated Environmental Vision 2050 in fiscal 2019. In fiscal 2022, we revised our fiscal 2030 greenhouse gas emissions reduction target to align with the 1.5°C level for temperature rise set by the Paris Agreement, and in fiscal 2024, we established promotion of a circular economy as a Fiscal 2030 Target. The results of our fiscal 2024 periodic review of our Fiscal 2030 Targets (environmental KPIs), which was based on our current medium-term management plan, confirmed that we are expected to be able to achieve each target and that major initiatives are progressing as planned.

Future issues include the promotion of specific initiatives to transition to a circular economy. We will continue to shift to environmentally friendly products that comply with the EU Ecodesign Regulation, and we aim to achieve zero emissions, which will minimize the environmental impact throughout the supply chain.

Furthermore, we will prepare to disclose information appropriately in accordance with nature-related information disclosure schemes (TNFD) and the newly published Japanese sustainability disclosure standards (SSBJ).

We will continue to contribute to the creation of a sustainable society by utilizing the technologies we have developed in the energy and environmental fields.

Reducing Environmental Impacts Throughout the Supply Chain

In its Environmental Vision 2050, Fuji Electric has positioned the reduction of greenhouse gas emissions and the promotion of a circular economy as important issues, and the company is working to achieve this environmental vision from a mediumto long-term perspective in order to solve challenges common to all its business activities, including in the R&D division, procurement division, and various factories.

R&D Initiatives

We are carrying out research and development aimed at creating new products that meet new needs related to green transformation (GX), and we are taking on the challenge of acquiring new technologies to reduce CO2 in a society through our products in areas such as fuel conversion to hydrogen and ammonia, CO2 recovery, and the electrification of heat processes.

Regarding the circular economy, we are carrying out development of technologies to reduce our environmental impact, such as evaluation and application technologies for recycled materials, in response to international regulatory trends, as well as creating new products to realize new business models. In addition, by participating in rulemaking activities for standards and regulations, we aim to harmonize efforts to reduce environmental impacts with economic activities.

Furthermore, we are formulating a GX strategy and roadmap to serve as guidelines for these activities.

Procurement Initiatives

In collaboration with our business partners, we are promoting the construction of a green supply chain.

Among our activities to reduce greenhouse gas emissions throughout the supply chain, we are currently calculating each business partner’s greenhouse gas emissions for procured goods. For business partners with high emissions, we will identify collaborative items for reduction through interviews and formulate action plans. Meanwhile, to calculate the carbon footprint (CFP)*1 on a per-material basis, we have formulated the Fuji Electric CFP Procurement Guidelines, are deepening business partners’ understandings by holding study sessions for them, and are collecting calculation data.

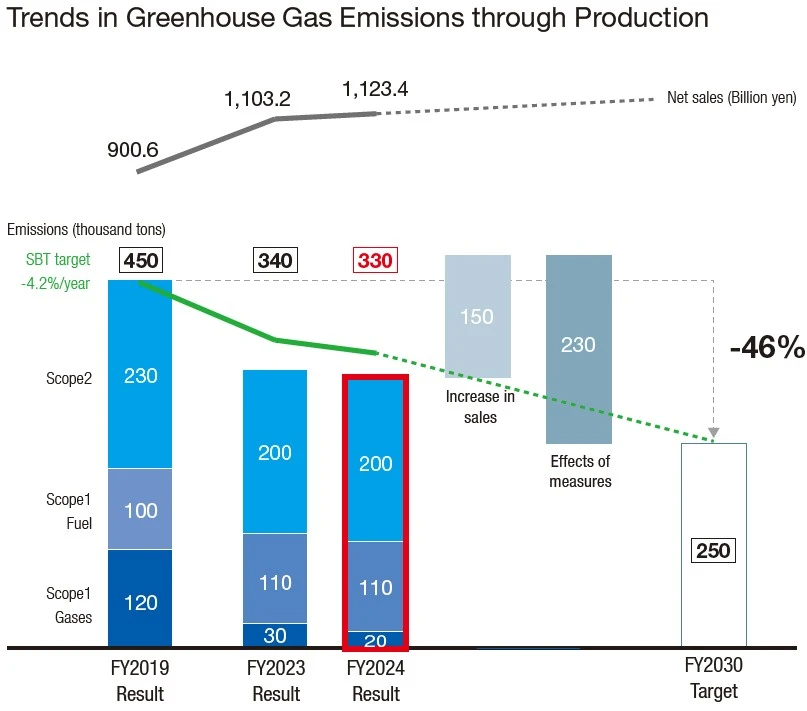

Manufacturing Initiatives

To achieve the Fiscal 2030 Target (a reduction of over 46% from fiscal 2019) for greenhouse gas emissions through production (Scopes 1+2), we are reducing environmental impacts by switching from greenhouse gases to electrification (renewable energy) through innovation in production technologies, reforming manufacturing processes, improving production efficiency, optimizing facility energy control, and upgrading to energy-efficient equipment. In reforming manufacturing processes, we will promote the development of underlying technologies such as those for lower-temperature operation and electrification of fuel-consuming equipment used in painting processes, including drying and baking. To improve production efficiency, we will promote DFM*2, which achieves manufacturing efficiency from the design stage, and aim to expand the production volume per hour. We will also achieve energy savings by monitoring and optimizing equipment operation. At our factories, we are systematically promoting the installation of solar power generation equipment and are expanding renewable electricity procurement to advance planned initiatives to achieve our goals.

Regarding the promotion of a circular economy, we will reduce our environmental impacts by improving material yields, promoting reuse, aiming for zero emissions to minimize waste and its amount sent to landfills, and managing and reducing use of chemical substances.

※2 DFM(Design for Manufacturing):製造しやすい設計

Business and Product Initiatives

We contribute to society’s CO2 emissions reduction through our environmentally friendly products. For inverters, a representative contributing product, we participated in a verification test by the Japan Electrical Manufacturers’ Association to visualize the actual amount of CO2 emission reduction. By controlling motor torque and rotation speed, we reduced energy use and visualized the resulting reduction effect on CO2 emissions (Scope 3). Through this initiative, we expect to contribute to more effective CO2 emissions reduction measures for companies and to the decarbonization of the entire industrial sector.

Regarding the promotion of a circular economy, our R&D, manufacturing, and business divisions will collaborate to advance the transition to environmentally friendly products that comply with ecological design regulations and CFP.

Initiatives to Achieve a Decarbonized Society

Fiscal 2024 Results and Progress

Major Initiatives in FY2024

As part of our initiatives to reduce greenhouse gas emissions through production, we promoted installation of solar power generation equipment at our production bases as part of an effort underway since fiscal 2022. In fiscal 2024, we installed and began operating a total of approximately 5,300 kW at five bases in Japan and two bases overseas. We also engaged in cross-functional energy-saving initiatives at all factories and promoted systematic activities such as selecting the most energy-efficient equipment when replacing infrastructure and production facilities. At our semiconductor production bases, which consume large amounts of electricity, we have signed three 20-year off-site PPA*1 contracts to expand our purchasing of renewable electricity.

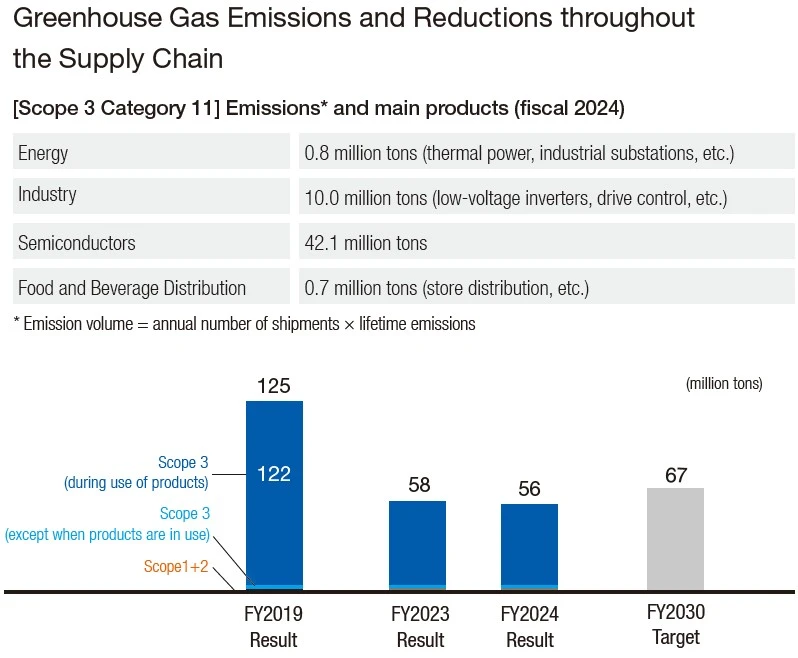

Regarding emissions during product use (Scope 3, Category 11), which account for approximately 95% of greenhouse gas emissions throughout the supply chain, we curbed emissions by increasing the ratio of high-efficiency products, such as 7th-generation IGBT power semiconductors.

*1 Off-site PPA: A system for purchasing electricity via the power grid facilities from renewable energy generation facilities installed off-site.

Initiatives toward 2030

We have verified the feasibility of our greenhouse gas reduction plan based on the projected production increases through fiscal 2030, in line with the FY2026 Medium-Term Management Plan.

We have confirmed that we are making progress toward achieving our targets for each indicator, including reducing greenhouse gas emissions throughout the supply chain— which covers our own factory production activities (Scopes 1+2) as well as material procurement, product shipment, and post-delivery emissions (Scope 3)—and contribution to CO2 reduction in a society through our products.

Our Fiscal 2030 Target is a higher reduction goal than the decarbonization target set by the Japanese government (NDC*2), and we will continue to advance our initiatives toward realizing a decarbonized society.

*2 NDC (Nationally Determined Contributions): The contributions set by a country.

Reduction of Greenhouse Gas Emissions throughout the Supply Chain (Scopes 1+2+3)

We calculate the greenhouse gas emissions generated in our supply chain based on the GHG Protocol, an international standard. For power semiconductors, Category 11 (emissions during product use), which accounts for the majority of Scope 3 greenhouse gas emissions, is expected to decrease due to expanded sales of 7th-generation IGBT modules with low power loss and the shift to silicon carbide (SiC) products. In Category 1 as well, which covers upstream emissions in the supply chain, we are carrying out activities to collaborate with and support our business partners. We aim to reduce greenhouse gas emissions throughout the supply chain to achieve the Fiscal 2030 Target (a reduction of over 46% from fiscal 2019, to 67 million tons or less).

Reduction of Greenhouse Gas Emissions through Production (Scope 1+2)

Based on the projected production increases centered on semiconductors, we are advancing the necessary measures to achieve a reduction of over 46% in greenhouse gas emissions through production (compared to fiscal 2019). To expand our purchasing of renewable electricity, we are securing a stable supply through long-term contracts, and we aim to increase renewable electricity’s share of total companywide electricity consumption*3 from 9% in fiscal 2024 to 55% by fiscal 2030.

*3 Electricity consumption: Amount of purchased electricity + Amount of solar power generated internally

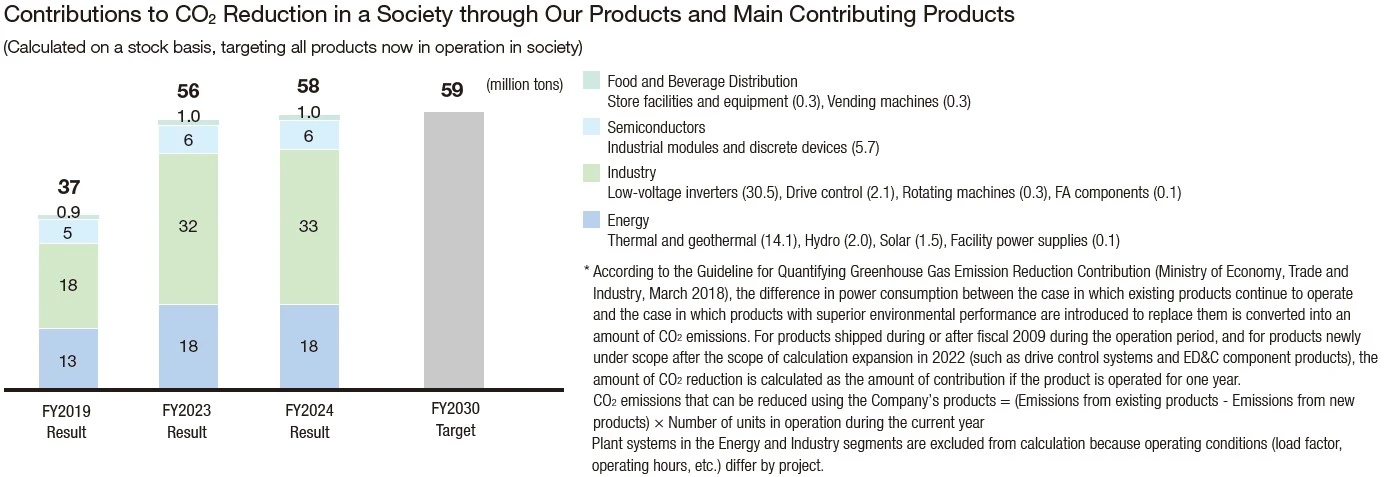

Contribution to CO2 Reduction in a Society through Our Products

Having defined our business domain as the energy and environmental fields, we began calculating the contribution to CO2 reduction in a society through our products in fiscal 2009, using this as an indicator of our contribution to achieving carbon neutrality. Each year, we have expanded the range of contributing products, and their sales composition ratio reached 30% in fiscal 2024; the increase is primarily centered on inverters in the industry business and the clean energy field.

Sales Composition Ratio of Contributing Products (Fiscal 2024 Result)

TOPICS

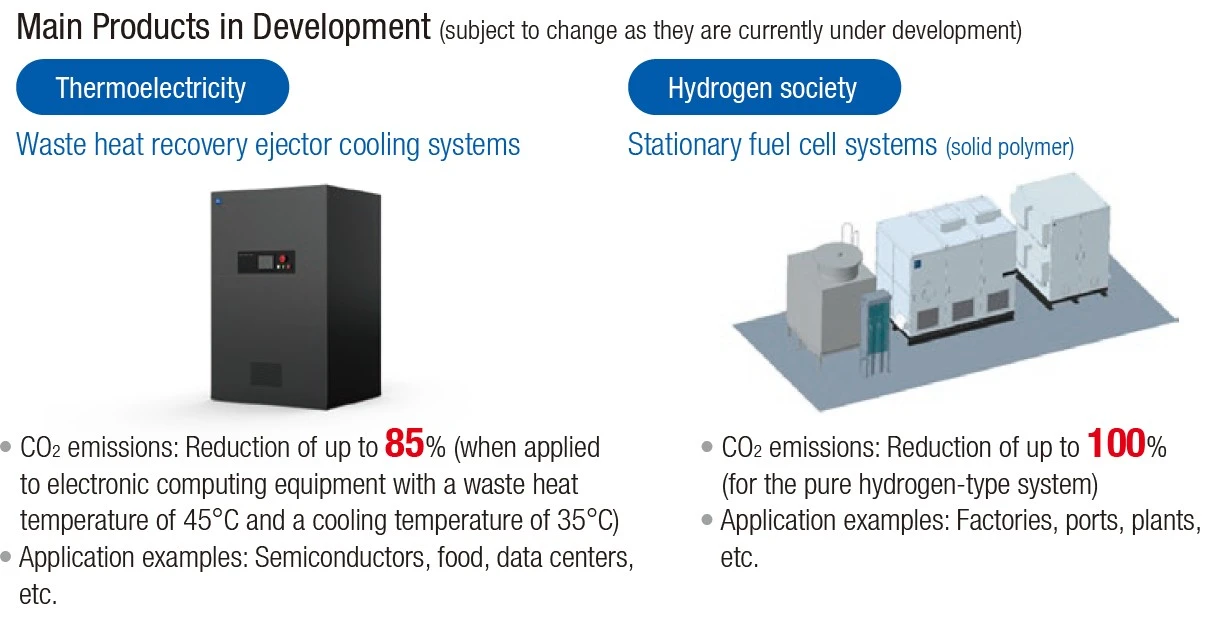

Expansion of GX Products in New Fields That Contribute to the Environment

While working to maintain and expand our existing businesses, we are also focusing on GX, digitalization, and our global business, and we will contribute to decarbonization by launching new products. Over the medium to long term, we will accelerate the development of environmentally friendly products with an eye to GX markets for new fields such as the hydrogen society, fuel conversion, and thermoelectricity. Through these initiatives, we will strive for further business expansion and environmental contribution.

Initiatives to Achieve a Recycling-Oriented Society and a Society That is in Harmony with Nature

Fiscal 2024 Results and Progress

Major Initiatives in FY2024

Regulations for the transition to a circular economy are advancing, particularly in Europe, and companies are required to implement initiatives to reduce their environmental impacts throughout their supply chains and to comply with information disclosure requirements. In fiscal 2024, as part of these efforts, we worked to create a framework and rules for transitioning to environmentally friendly products.

In addition, we worked to reduce the amount of waste sent to landfills, particularly by strengthening sorting and waste disposal contractors at our overseas production bases, and have maintained a high standard with a ratio of 0.15%.

Initiatives toward FY2030

We are preparing to transition to environmentally friendly products that meet the requirements of environmental regulations in Japan and overseas. In response to demands for per-product traceability disclosure, including resources and environmental impacts, we are working to create a framework to support the calculation of carbon footprints (CFP) and the EU Digital Product Passport (DPP)*.

*Digital Product Passport (DPP): A mechanism to provide information on topics such as product sustainability in the form of an electronic record

Transitioning to Environmentally Friendly Products

To realize “manufacturing with no environmental impacts throughout the entire lifecycle,” we are reviewing the requirements for environmentally friendly products. In product development and design, in addition to conventional requirements such as energy savings and resource savings, we will add requirements such as recyclability, CFP disclosure, waste reduction, and support for biodiversity.

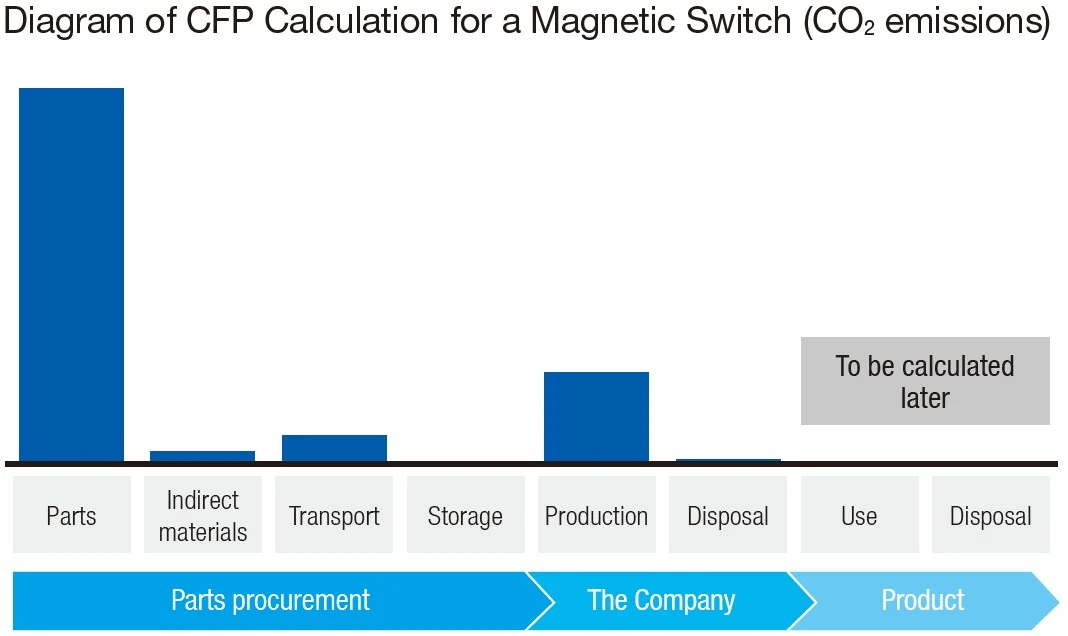

Addressing Carbon Footprint (CFP)

We are implementing initiatives to quantify greenhouse gas emissions over product life cycles as the amount of CO2 emissions.

In fiscal 2024, we conducted trial calculations from procurement to production for two representative models (magnetic switches and vending machines) and identified challenges for future calculations.

In fiscal 2025, we will expand the range of models subject to calculation to include low-voltage inverters and semiconductors, and we will work to collect primary data in collaboration with our business partners.

Information Disclosure Based on the TCFD and TNFD Recommendations

Since expressing our support for the Task Force on Climaterelated Financial Disclosures (TCFD) in June 2020, we have reflected the results of our analysis of risks and opportunities arising from climate change in our business strategies and have updated our information disclosures based on the TCFD recommendations.

In fiscal 2024, based on the framework of the Taskforce on Nature-related Financial Disclosures (TNFD), we newly evaluated the degree to which our manufacturing bases depend on natural capital, the impact such bases have on natural capital, and risks and opportunities for our business, following the LEAP approach recommended by the TNFD.