IR Information

Manufacturing and Procurement Cross-Functional Strategy Supporting Business Growth Fuji Electric Report 2025

Improving productivity and strengthening the supply chain by utilizing digitization and AI technologies

Managing Executive Officer

Corporate General Manager, Production & Procurement Group

Takashi Obinata

We have been promoting high-efficiency, high-quality manufacturing driven by our strong on-site capabilities and advanced production technologies; a stable supply system based on optimal global production centered on local production for local consumption; and the enhancement of the human resources and teamwork that form the foundation for these strengths.

Today, the manufacturing industry faces an increasingly uncertain environment, including labor shortages and the risk of supply chain disruptions. The advancement of digitization and AI technologies; the shift to a decarbonized, circular economy; and the challenge of controlling the associated administrative costs have also become key issues.

To solve these issues, in our FY2026 Medium-Term Management Plan, we are working to improve productivity by utilizing digital technology. We will optimize the entire value chain from development and design, production management, and manufacturing to sales and after-sales services in order to promote business process reform, while aiming to further strengthen profitability by building a production system that can respond to changes in demand and by reducing costs. Furthermore, we are working to strengthen our global business continuity plans (BCPs) to ensure stable material procurement over the medium to long term, and we will also promote the optimization of material inventories and improve operational efficiency through digital collaboration with our business partners.

The Strengths of Fuji Electric’s Manufacturing

-

1.

Strong On-site Capabilities and Advanced Production Technologies

-

We achieve high-efficiency, high-quality manufacturing by combining improvement capabilities driven by the high level of technology and skills at our manufacturing sites with our production and automation technologies.

-

We advance our production systems and optimize quality, cost, and delivery (QCD) across the supply chain through real-time visualization of factory management indicators and on-site data, and through improvement activities.

-

-

2.

Optimal Global Production Collaboration

-

We strengthen our community-based production systems by transferring and passing down cutting-edge technologies, equipment, and production management systems from our mother factories in Japan to our overseas production bases.

-

We strengthen our global production systems through collaboration between production bases, thus building a resilient, flexible, and stable supply chain.

-

-

3.

Human Resource and Team Capabilities by Cultivating Engineers and Skilled Workers

-

We are increasing the number of engineers with the ability and teamwork skills for autonomously innovating production technologies by providing practical global training on production technology, skills, and manufacturing expertise, as well as digital human resource cultivation, for young engineers and mid-level leaders at our bases in Japan and overseas.

-

The Evolution of Manufacturing to Respond to Change

※2 SCM:Supply Chain Management

Concurrent Development Through PLM Reform and SCM Integration

We aim to reform our business processes, shorten delivery times, and improve product quality through concurrent development that links PLM (which covers the product lifecycle from planning, development, and design to maintenance) with SCM (which covers the process from order receipt to manufacturing and shipment). In addition to promoting design standardization and business system construction, we aim to realize highly efficient, compact lines by reducing operational rework (i.e., work to confirm mistakes or ambiguities in instructions from previous manual processes) through integration with procurement data, and by utilizing AI simulation technology for optimal process design and verification.

Furthermore, by using 3D design data to digitally verify product configurations and assembly feasibility (e.g., interference and clearance) in a virtual space and then making design changes or corrections based on the verification results, we are working to reduce losses during the production stage and to improve product quality.

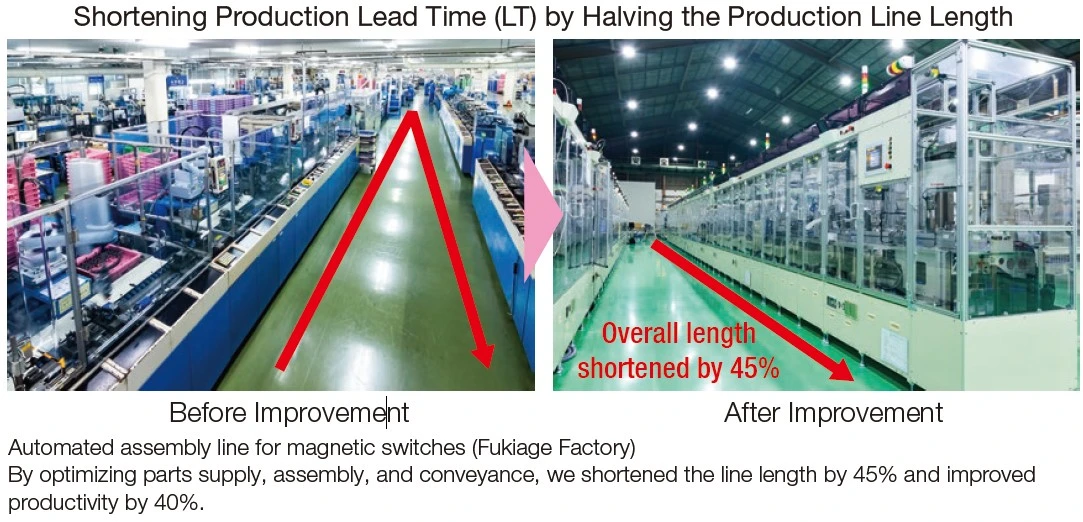

Improving Productivity by Advancing Production Technologies

In response to the launch of new products in growth markets and to the expansion of overseas businesses, we are working to increase our production capacity by advancing our production technologies, executing timely plant and equipment investments, and further strengthening our global production systems.

We are automating bottleneck processes that were conventionally difficult to automate (e.g., welding, attachment of soft parts, and visual inspection) using control technology for multi-axis 3D robots and digital processing technology that combines image recognition with CAD. Furthermore, by utilizing multivariate analysis of process data and AI technology to foresee and predict equipment abnormalities, we are working to improve productivity and increase our global product supply capacity.

By advancing these production technologies, we are aiming to achieve a 20% improvement in productivity in fiscal 2026 (compared to FY2023). We achieved a 6% improvement in fiscal 2024 (compared to FY2023).

Initiatives to Improve Quality

As for quality, each year we formulate the High Reliability Activities Policy and apply it to each business division and factory to promote improvement activities. To enhance the degree of product refinement at the development and design stages, we are incorporating plans to acquire new technologies into our design reviews, in addition to the technologies our factories already possess. Furthermore, we are working to strengthen our quality management framework by re-examining our operational procedures.

In addition, at our production sites, we are automating visual inspections using image diagnosis powered by AI technology and are proceeding to digitize quality records. We utilize this data for statistical process control (SPC) and other methods to eliminate human error and the risk of equipment defects.

For process quality, regarding the management status of our manufacturing processes, in addition to the internal audits conducted at each factory, we also carry out mutual diagnoses by experts from other bases. To improve our quality control standards, we reflect the results and findings in our frameworks and rules.

Sustainable Procurement

CSR Procurement Initiatives

Based on our basic policy of co-existence and mutual prosperity with our business partners, we work to deepen their understanding of our CSR approach and the initiatives they should observe and implement according to the “Fuji Electric CSR Procurement Guidelines,” thereby reducing CSR risks and creating business opportunities.

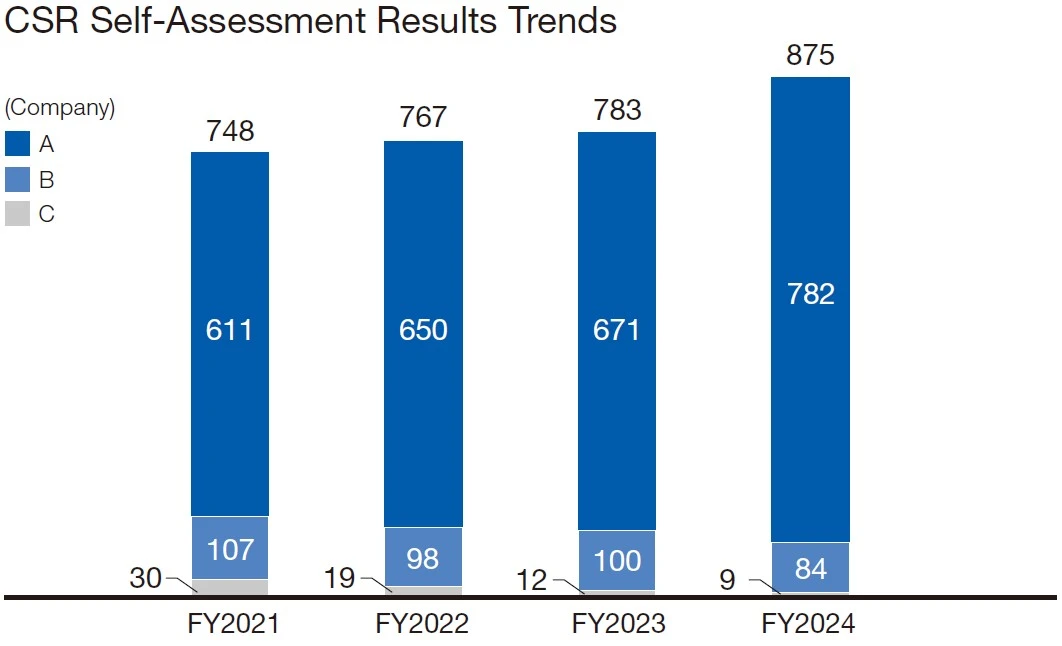

Self-Assessment of CSR Procurement

To understand the status of our business partners’ CSR initiatives and improvements, we conduct an annual CSR selfassessment. We also hold CSR briefings and interviews with business partners to share the issues we face and implement PDCA cycles for collaborative improvement activities. In fiscal 2024, we conducted assessments of 875 business partners, which covered 80% of our purchases over the last three years. As a result of these activities, the percentage of Rank A business partners has been increasing by the year, reaching 89%, a three-percentage-point increase from the previous fiscal year. In fiscal 2025, we plan to assess 880 business partners, and we will promote thorough implementation and reinforcement of CSR in our supply chain by sharing issues and making continuous improvements collaboratively.

CSR Audit Initiatives

To improve the effectiveness of CSR procurement, we conduct on-site CSR audits of our business partners. In fiscal 2024, we conducted on-site audits of 17 companies, focusing on business partners with Rank B and C evaluations. We confirmed their understandings of the importance of CSR activities and the statuses of their actual activities. At the same time, we communicated with our business partners to ensure alignment with respect to evaluation criteria and improvement methods for each activity, and we shared issues with each other. Furthermore, to expand our on-site audits, we also trained our own auditors; in fiscal 2024, the number of auditors increased by 12 to a total of 19. In fiscal 2025, we plan to conduct more on-site audits and to further increase the number of auditors, and we will strengthen our CSR procurement by communicating directly with business partners that handle single-source items and critical components.

Contributing to Business Continuity through Stable Procurement

Initiatives for Purchasing from Multiple Suppliers to Prepare for Emergencies

We conduct risk assessments for the approximately 200,000 parts and materials that we order on an ongoing basis and are promoting visualization of single-source items and transitioning to multi-sourcing. In fiscal 2024, we established multi-sourcing for approximately 85% of our procured items (a five-percentage-point increase from the previous fiscal year). In fiscal 2025, we will aim for a 90% multi-sourcing rate and promote the development of new suppliers to eliminate single-source items, aiming to build a resilient supply chain.

Response to Natural Disaster Risks

In Japan, we utilize a disaster prevention system that can identify business partners located in areas where special warnings on earthquakes or weather have been issued. We have established a system for quickly ascertaining whether our business partners have been affected and the impacts on our company, enabling us to promptly formulate countermeasures. We are expanding the scope of registration of this disaster prevention system to include secondary business partners, with the number of registered bases reaching approximately 12,000 in fiscal 2024. Meanwhile, in response to disasters occurring overseas, we conducted a trial of this same system in fiscal 2024. In fiscal 2025, we will proceed with a full-scale introduction targeting 200 bases, increase registration of overseas business partners, and further strengthen our global BCP.

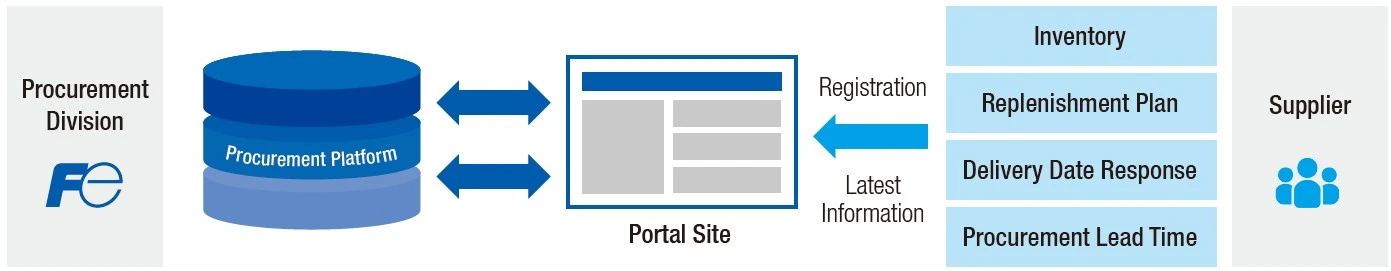

Improving the Efficiency of Procurement Operations through Digital Collaboration

By digitally linking procurement-related data with our business partners, we aim to reduce material inventory balances by shortening procurement lead times, respond flexibly to fluctuations in production volume, and achieve stable procurement that does not affect production processes. In addition, by digitally linking the corporate information of our business partners, including CSR and BCP data, we will build a procurement system that facilitates real-time information sharing, thereby transforming operations that were previously handled by email or phone to improve speed and efficiency.