Automation and energy savings: Factories

-

Revolutionizing a yam sorting plant using IoT

-

Uniquely evolving AI technology

-

Break away from data collection and analysis up to individuals.

-

Freeing from human control of power and heat

-

Predicting failures using vibrations

-

Solving on-site problems with data

-

Seeing the skills of experts beyond the smart glasses

-

Evolving inspection devices for infrastructures and equipment

Resolving labor shortages using AI and IoT

Revolutionizing a yam sorting plant using IoT

Construction of a yam boxing line that is product-friendly and does not require human labor

JA Obihiro Kawanishi introduced our solutions with a backdrop of labor shortages at their yam sorting plant. These solutions include precise and efficient product transportation and boxing systems by using our ALPHA7 servo system, construction of a production control system that enables traceability, and visualization and understanding of the progress of yam selection enabled by using OnePackEdge.Full introduction of technology has solved the labor shortage and improved the shipping capacity of the yam sorting plant.

Uniquely evolving AI technology

New value creation and automation using analytics and AI

Fuji Electric has a wealth of experience in analytics and AI introducing multivariate statistical process control (MSPC) technology that we have enhanced independently. Our AI technology is installed not only on-premises and in the cloud, but is also used in edge controllers such as SignAiEdge, and has been very effective in detecting signs of abnormality. We are contributing to the use of automation by creating new value from on-site data.

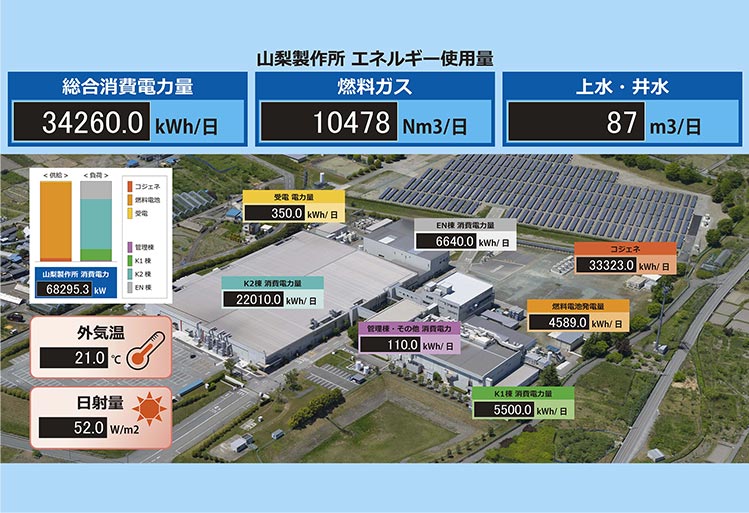

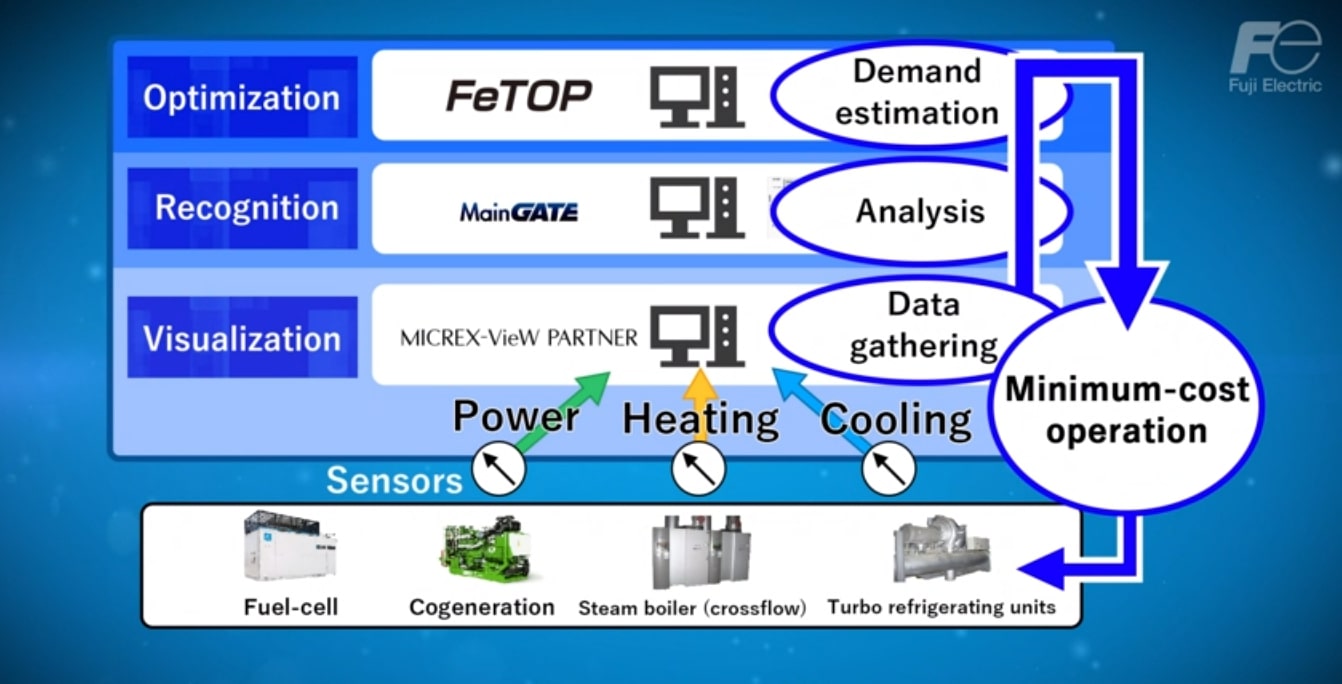

Freeing from human control of power and heat

Visualization, understanding, and optimization of thermoelectric use by means of IoT

At our Yamanashi Factory where power semiconductor wafers are manufactured, Fuji Electric forecasts power and heat demand using an EMS solution for the entire factory. The energy supply equipment is controlled based on these forecasts, which makes it possible to supply power and heat in the most energy-saving combination. This has resulted in a reduction of energy consumption by 34%.* Management and control using IoT has also led to measures against labor shortages.

-

*

-

Energy consumption in 2015 compared to 2010.

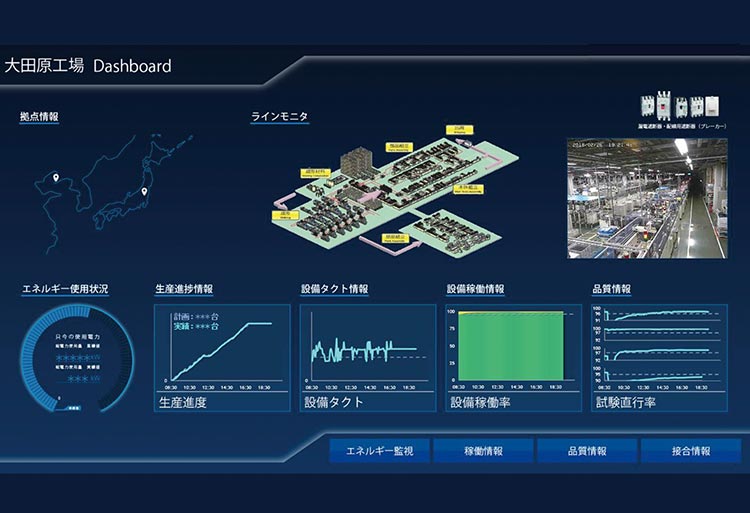

Break away from data collection and analysis up to individuals.

Enabling non-stop equipment by collecting and analyzing site data

Fuji Electric’s OnePackEdge collects environment and processing data from CNC and PLC devices and various sensors, and accumulates the data for each product and production cycle. It is possible to maintain and manage the systems so that they are able to operate normally and satisfactorily at any time by means of factor analysis such as equipment malfunctions and defective products. This also enables us to break away from individualistic data collection and analysis and increase our productivity.

Solving on-site problems with data

Utilizing data analysis by MSPC to detect abnormalities in the pressing process

During the progressive pressing process at our Mie Factory where our vending machines are manufactured, the punched out scraps would frequently float up and adhere to the punch. We conducted analysis using multivariate statistical process control (MSPC) technology to solve the problem. We have successfully eliminated quality defects and avoid mold damage by being able to detect signs of abnormality and take measures before the event occurs.

Efficient extension of service life and replacement of aging equipment

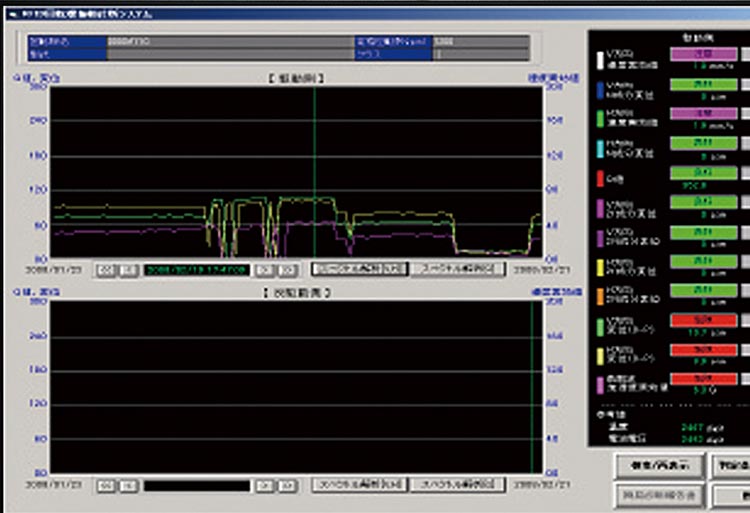

Predicting failures using vibrations

Efficient maintenance of machinery and equipment by failure sign monitoring system for rotating machines

The Fuji Electric Wiserot is wireless diagnostic system for rotating machine vibration.

Utilizing our unique expertise, Wiserot can constantly monitor the vibration of rotating machines operating on production lines and other important equipment, and detect signs of abnormality at an early stage. In addition to being able to prevent breakdowns of individual machines and equipment, our Wiserot system can also be used to formulate equipment replacement plans, leading to a reduction in costs due to production losses.

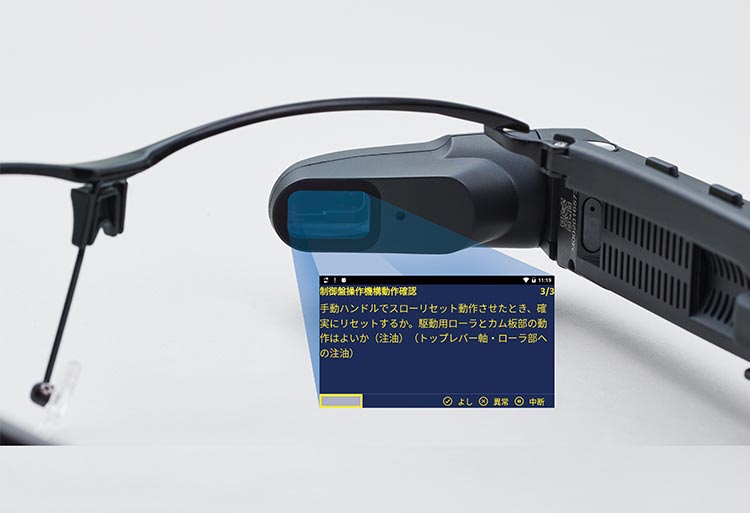

Seeing the skills of experts beyond the smart glasses

Expertise of experienced personnel can be used in real time

In addition to making it possible to share information in real time about the on-site situation in remote areas using images and voice during maintenance work, our wearable remote work support package enables workers to be instructed by displaying documents and writing on images. Efficient and highly accurate maintenance work is made possible when skilled personnel give instructions from the headquarters.

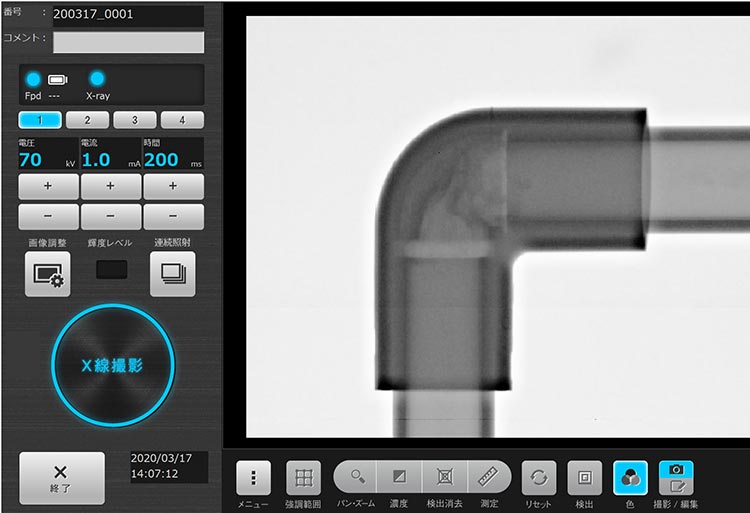

Evolving inspection devices for infrastructures and equipment

X-ray inspection equipment for piping enables efficient infrastructure inspections

An urgent need exists to take measures against aging infrastructures, but it is not easy to understand the condition of pipes when their interiors cannot be easily seen. Fuji Electric’s X-ray inspection device for piping is non-destructive and makes it easy to inspect piping, and because this is the world’s smallest and lightest device, it is also excellent for use in confined spaces and at heights. This device is battery-powered and can be used outdoors without an external power source.