Automation and energy savings: Cities

Reducing labor and personnel at distribution sites

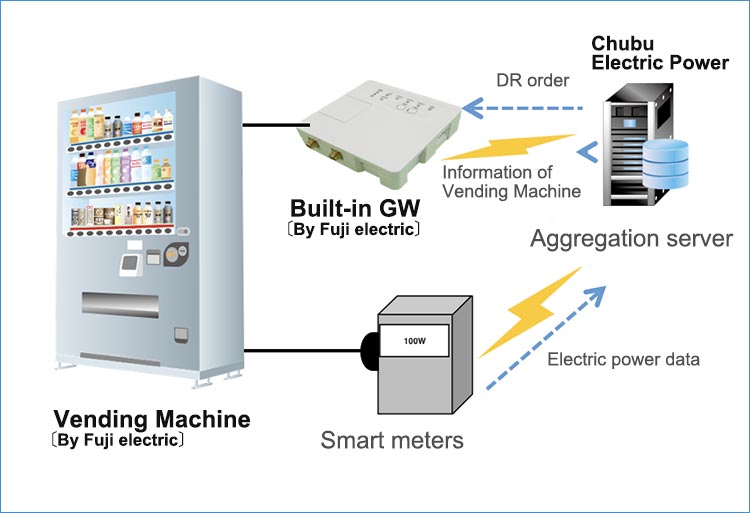

Vending machines can supply and demand power

Creating a virtual power plant to demonstrate power supply and demand balancing capabilities using vending machines

There are about 2.13 million soft drink vending machines installed throughout Japan. Vending machines have excellent heat storage, a relatively fast response time, and a demand response (DR) potential of approximately 200 MW or more. Fuji Electric has started a remote-controlled virtual power plant (VPP)* demonstration project in collaboration with Chubu Electric Power. We are aiming to create a new business model using vending machines by gaining the capability of balancing the supply and demand in the market.

-

*

-

A virtual power plant (VPP) is a mechanism that utilizes IoT to collectively control distributed power generation equipment and large storage batteries and make them function as a single power plant.

Management and control of energy for in-store equipment

Management and control of energy for in-store equipment

Management system centralizing temperature and lighting management and equipment monitoring

Management system centralizing temperature and lighting management and equipment monitoring

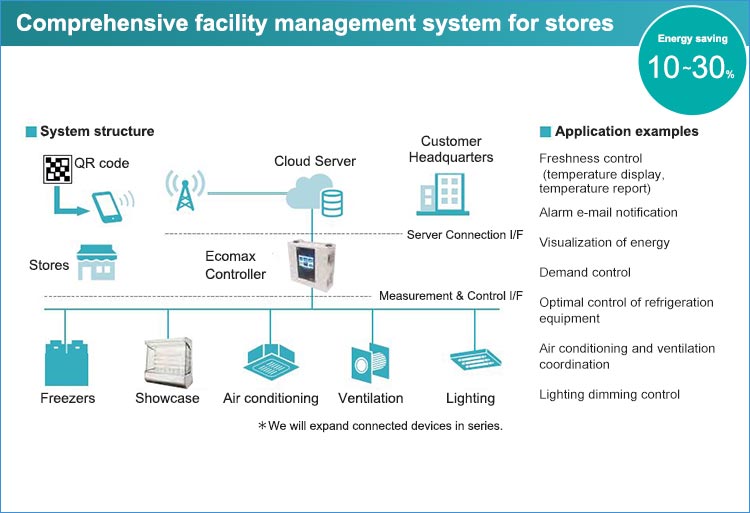

Our Ecomax Controller comprehensive facility management system for stores monitors the energy consumption and operating conditions of in-store refrigerators, showcases, and air conditioners 24 hours a day. The Ecomax Controller automatically controls the equipment optimally to achieve high energy savings.* Remote monitoring and control are possible by connecting to the Internet, and a network that connects the headquarters and multiple stores can also be created.

-

*

-

According to our in-company comparisons.

Safe and secure social infrastructure supporting daily life

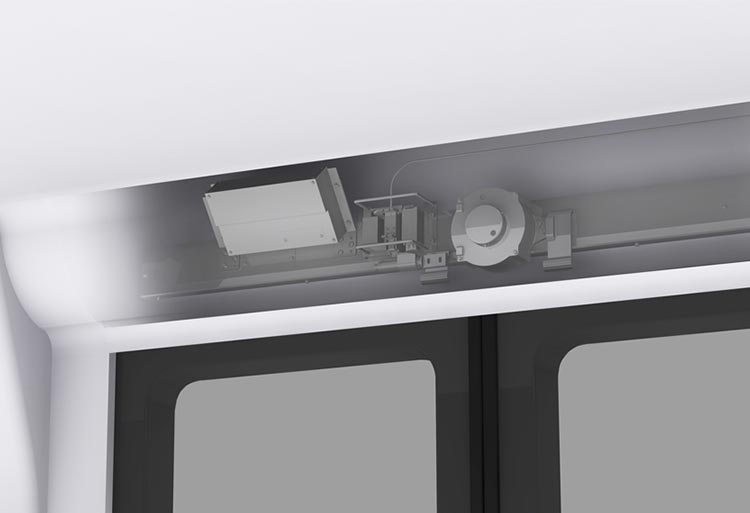

Use in the e-Palette

Providing electric driven door systems for the Toyota Motor e-Palette

Our electric driven door system is used in Toyota Motor’s low-speed autonomous driving e-Palette electric vehicle. Our share of electric driven door systems for railway vehicles is about 50% in Japan. We have delivered about 75,000 units worldwide, supporting the commuting and lives of about 3 billion people annually. Our electric driven door system was selected as the technology for the e-Palette because of its proven reliability, safety, small size, and modular configuration.

High technology supporting bullet trains

Main converter supporting the propulsion system of the Shinkansen N700S series

Our main converter is used in the propulsion systems of the world-class Shinkansen bullet trains. The main converter controls the rotational speed of the traction motor which controls the running speed. Our Hybrid SiC, which turns the current on and off at high speed, precisely controls the electric power, and this highly reliable technology enables the high-speed running of the Shinkansen.

Making electric vehicles last longer and go farther

High-performance IGBT modules making electric vehicles go farther

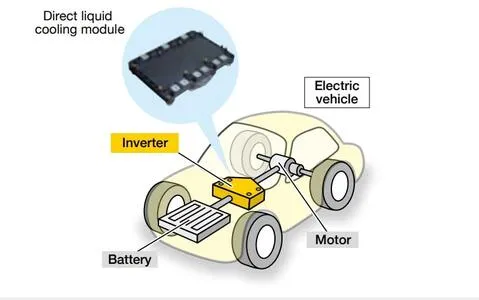

Electric vehicles (EVs) are required to be smaller, lighter, and more efficient in order to reduce their impact on the environment and improve their cruising range. Our motor drive inverters are equipped with RC-IGBT* modules that enable miniaturization and low loss. Since FY 2019 Fuji Electric has been mass-producing direct liquid cooling modules that use a direct liquid cooling structure with better heat dissipation performance than conventional products.

-

*

-

Compared to the use of two chips arranged separately, RC-IGBT enables a significant reduction in size by having two types of semiconductors (IGBT and freewheel diode) with different functions arranged and operated alternately in a straight line on a single chip.

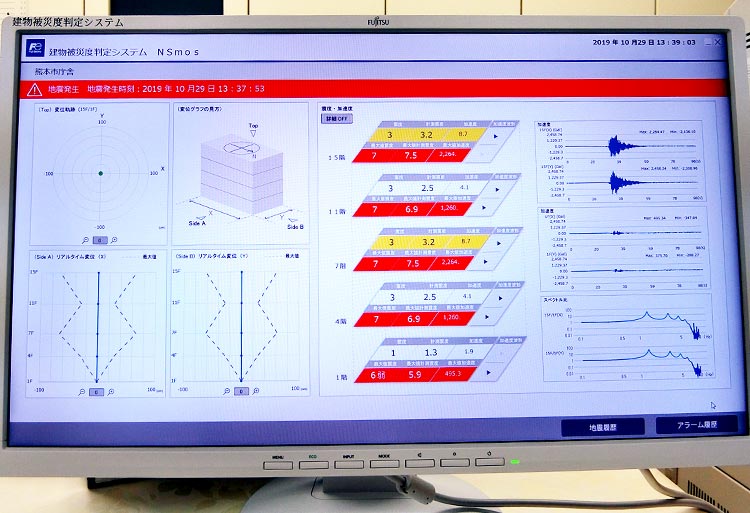

Instantly determines damages from earthquake

Instantly determines the degree of damage in the event of an earthquake

Fuji Electric’s structural health monitoring system is used in the earthquake building damage assessment system of Nikken Sekkei Co., Ltd., which Kumamoto City has installed in its main government building. Vibration sensors measure the shaking of the building with high accuracy, from slight to strong vibrations, and structural analysis technology is utilized to enable the strength of the building to be visualized and the degree of the damage to be promptly determined.