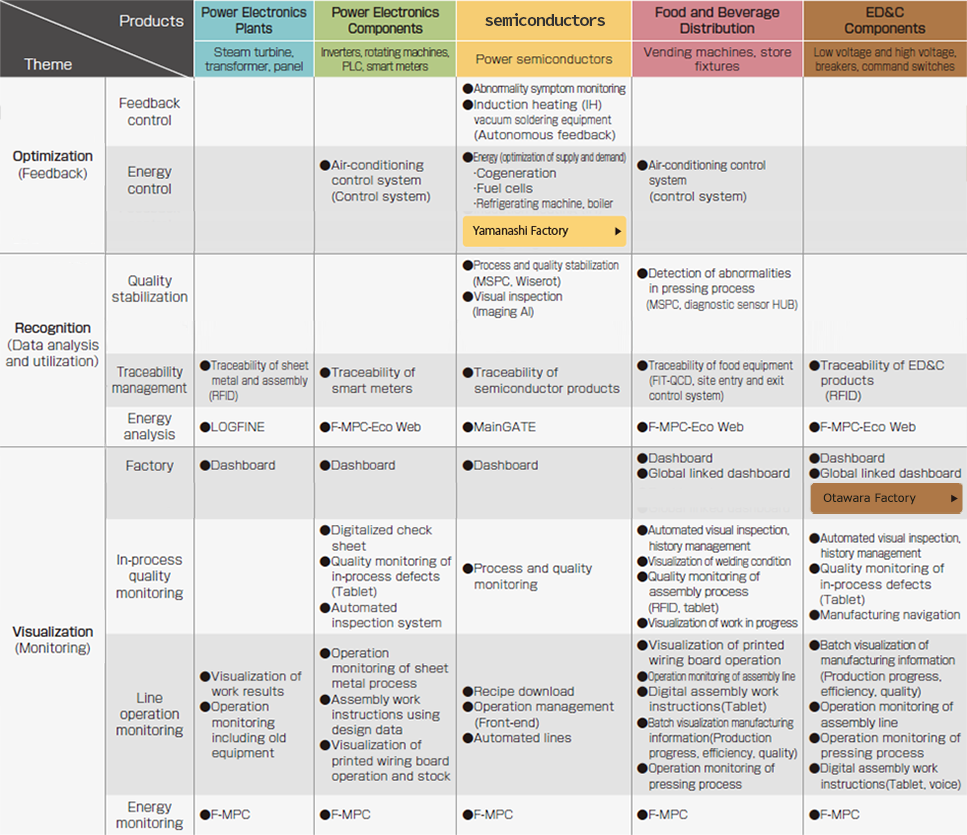

Implementation examples

tasks and energy

(domestic and overseas factories)

Otawara Factory

(Manufacture of electrical equipment)

-

Target production tact achieved (efficiency: + 5%)

-

Production order delivery time achievement rate (99% ⇒ 100%)

-

Stoppage due to bottleneck equipment trouble (20% ⇒ 2%)

-

Comparison of same model production information between Japan and China

-

Contracted power usage maintained by peak shaving

of energy

(energy saving rate: ▲34%, electric power self-sufficiency rate:100%)

Yamanashi Factory

(Manufacture of semiconductors)

-

Recipient of FY2016 Energy Conservation Grand Prize (Minister of Economy, Trade and Industry Prize)

-

Cogeneration Award 2017, Award of Excellence

-

Efficient air-conditioning equipment for clean rooms

-

Equipment for business continuity planning (BCP) (cogeneration, fuel cells, voltage sag countermeasure devices)

-

Optimization of energy supply and demand balance by factory energy management system (FEMS)

Implementation examples in Fuji Electric's own factories