FRENIC-Lift (LM3U)

Product Information

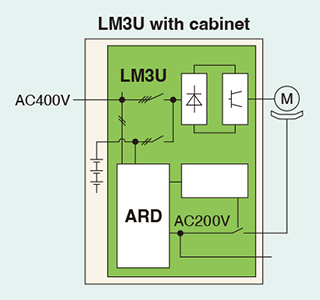

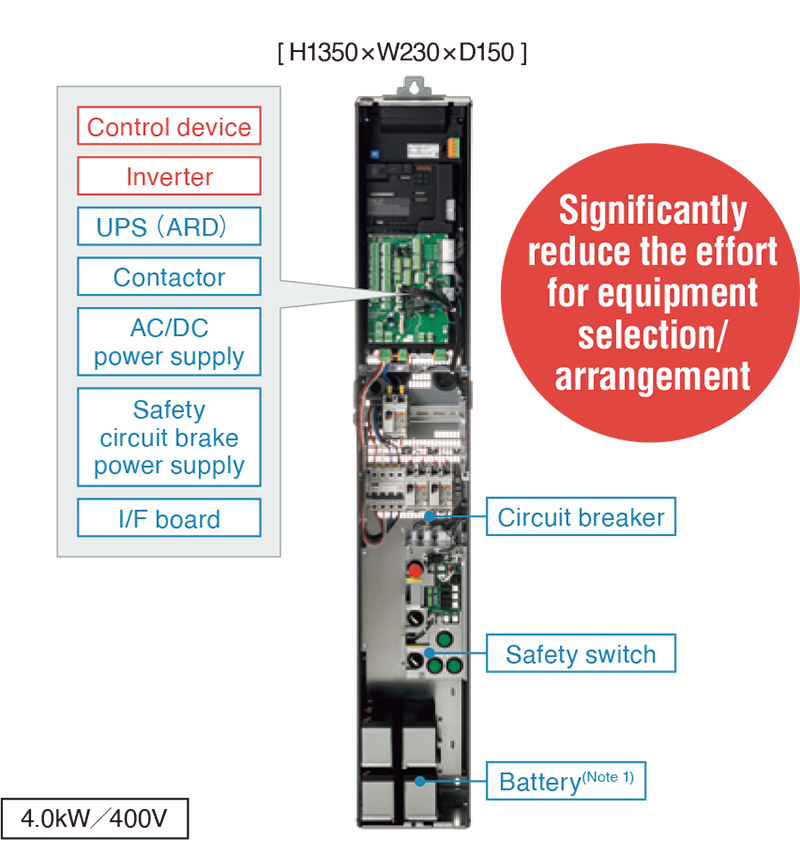

The controller, main power circuit, ARD, and other necessary equipment are integrated into the inverter.

A single unit is all it takes to begin lift operations.

Compact Design for Installation in Confined Spaces

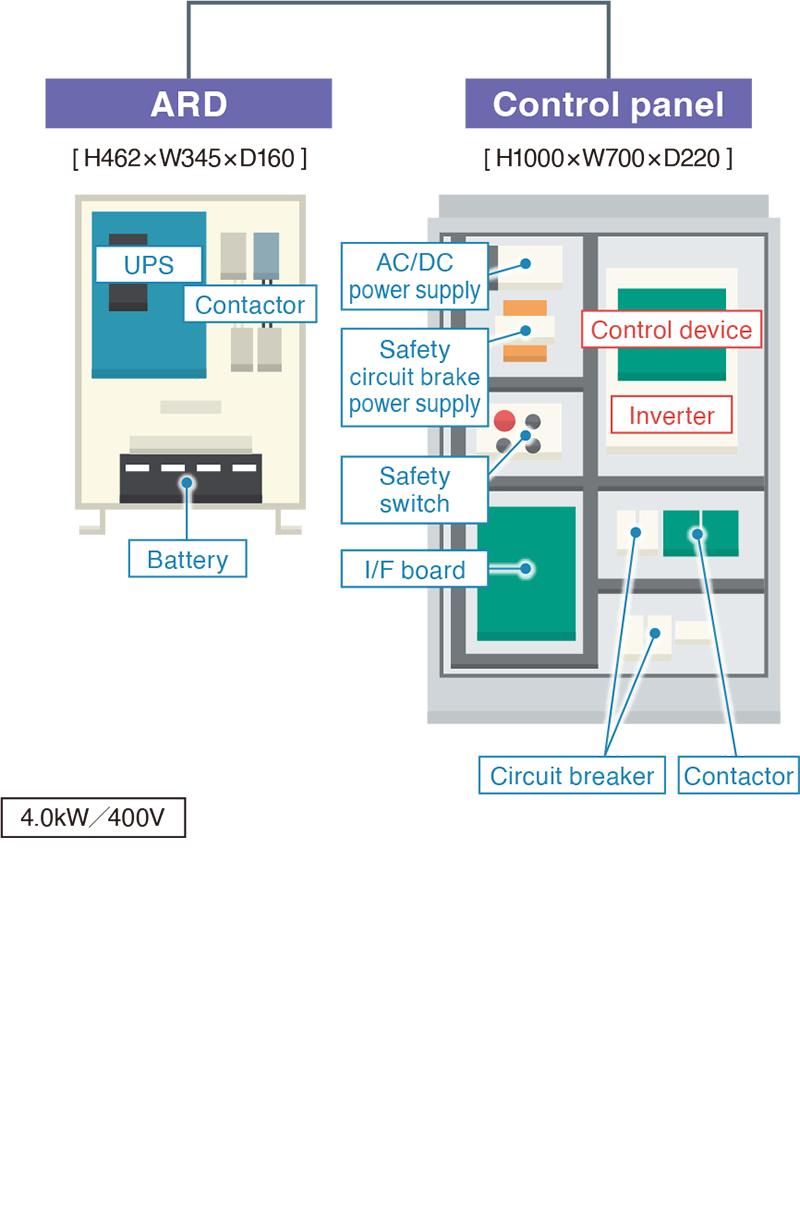

Unit type that integrates necessary parts for ARD(Auto Rescue Device) operation. Two cabinet types (control panels) are also available, each equipped with a breaker and battery. They both contribute to space savings, being compact with a much smaller footprint than conventional separately-mounted ARDs.

Footprint :179,502cm2

Layout example inside a control panel

Footprint : 46,575cm

-

Note

-

Battery must be arranged for by the customer.

POINT

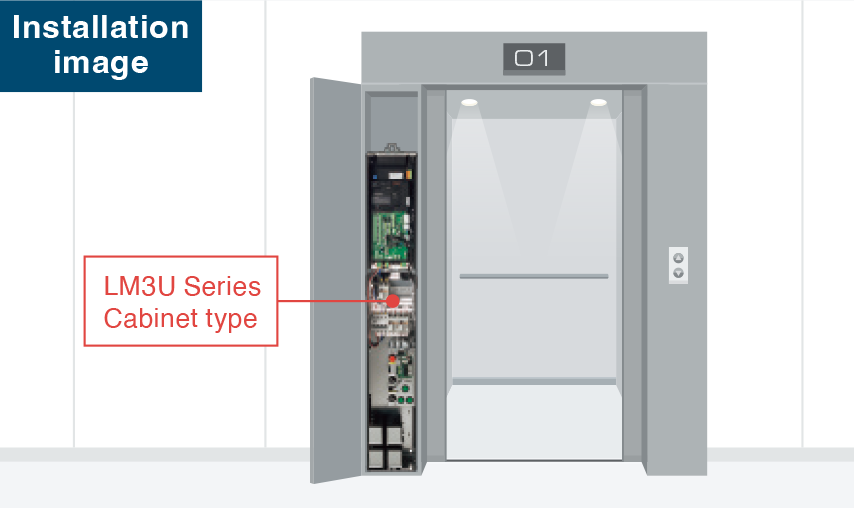

Eliminates machine room and contributes to lobby design

All-in-one design eliminates the machine room, and its industry-leading thinness allows installation without affecting lobby design or surrounding appearance.

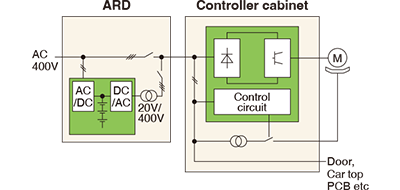

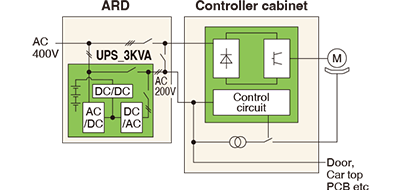

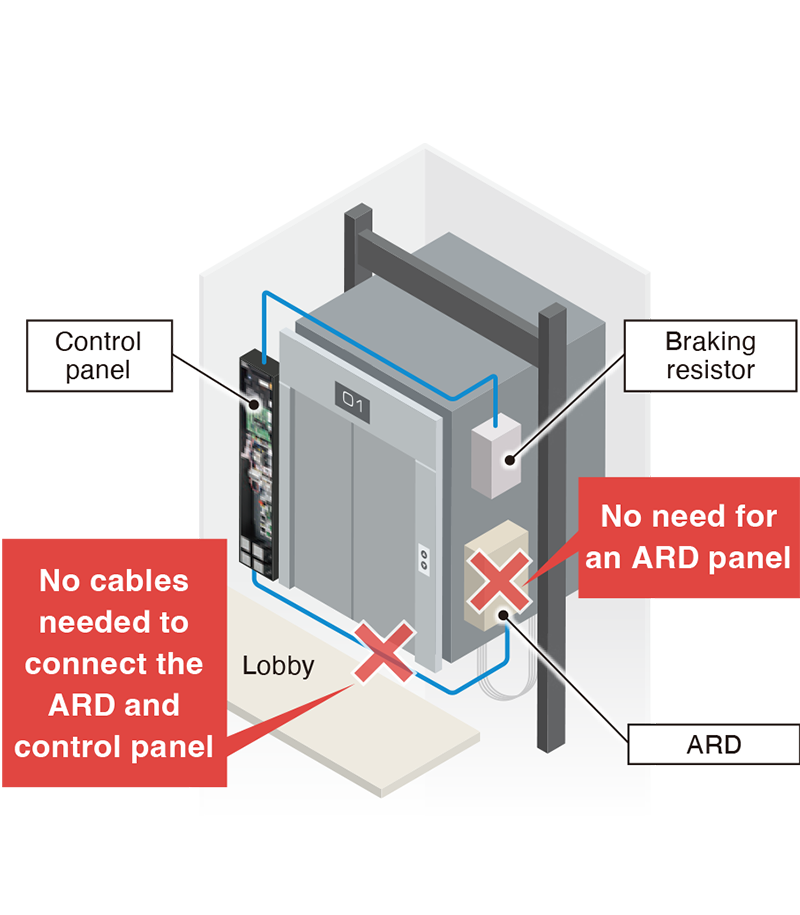

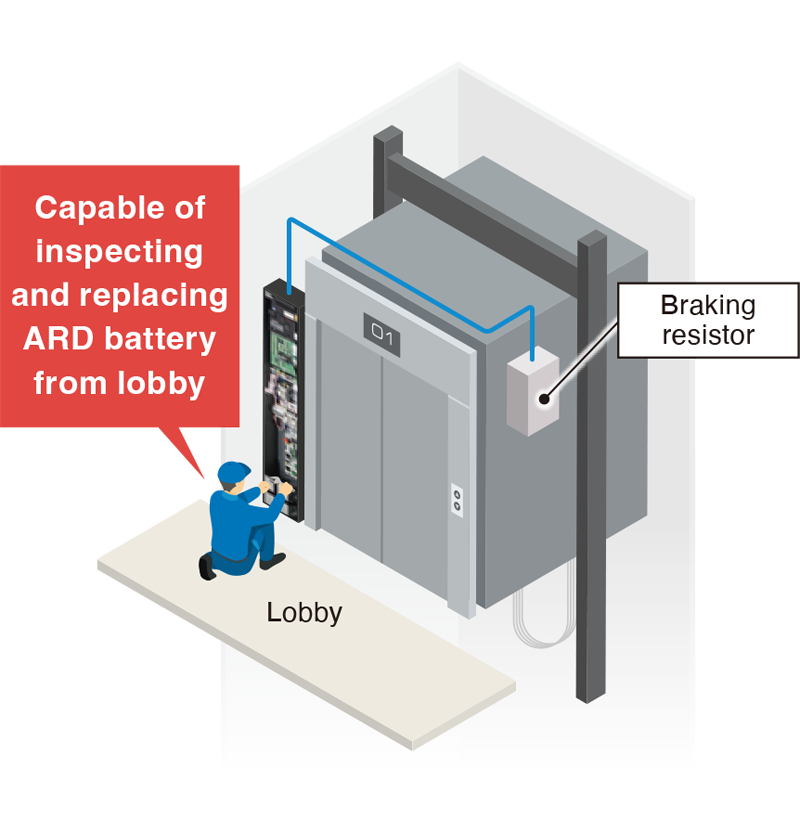

Built-In ARD Reduces Installation Costs and Simplifies Maintenance

The built-in ARD eliminates the need for ARD/UPS installation panels and inverter connection cables, thereby reducing installation costs. It requires no complicated wiring work, thus shortening work time from delivery to installation.

It enables the ARD battery to be inspected and replaced from the lobby, thus eliminating the need to work inside the shaft. It also comes with a contactorless solution compliant with EN81-20 that decreases maintenance work and reduces contactor-induced noise similar to a safety circuit when using two contactors.

POINT

Simplifies control panel installation

The control panel can be installed easily and quickly without additional components because the main unit contains all the necessary equipment.

Combined LOP/COP Available

It offers a total solution that includes not only the inverter but also the LOP/COP.

LOP : Landing Operation Panel

COP : Car Operation Panel

-

Note

-

Contact our sales department for details.

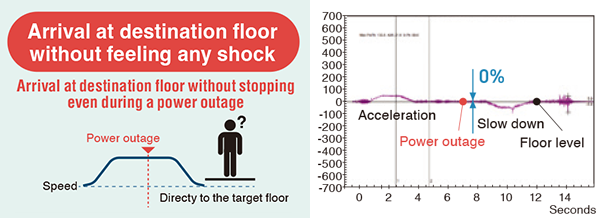

It features the industry’s first shockless stop function that safely stops the lift at the nearest floor in the event of a power outage.

It reduces the risk of injury to passengers, even in areas with frequent power outages.

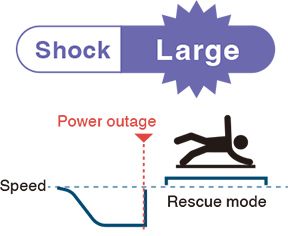

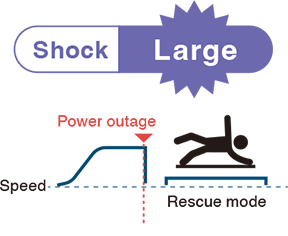

Shockless Stop Function

Reduces risk of passenger injury

Its shockless stop function protects passengers from the risk of injury caused by sudden braking during power outages.

The function ensures a high level of safety by allowing the lift to arrive at its destination floor without feeling any shaking even when braking.

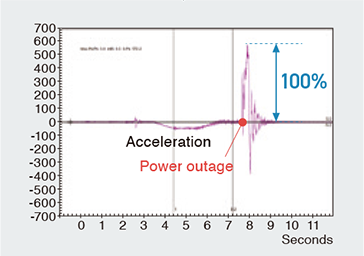

Reduces shock when stopping by 80% Moves safely to nearest floor

The inverter drive reduces shock during power outages compared to conventional ARD systems. Inverter braking also allows the lift to move to the by 80% nearest floor with hardly any shaking.

Shockless stop function

No shockless stop function

AC Drives (Low Voltage) Support

Download documents

Column

Understanding application, benefits, basic structure, case study, types, and Fuji Electric's inverters with this video.

December 27,2021

Understanding the basics: Differences between inverters and converters

January 20,2021

How and what does an inverter take control of? A brief explanation to grasp the basic structure.

January 20,2021

The fundamentals of inverters and their uses.

January 20,2021