Tracing the Roots of Our Energy and Environment Businesses

History of General-Purpose Inverters (Part 2)

1980s and 1990s: Expansion of general-purpose inverter applications achieving

Transistor inverters, which were originally utilized for energy-saving purposes in fans and pumps, are now being used more widely in factory automation equipment and industrial machinery. This is because these inverters have achieved higher performance, compactness, and cost performance compared to conventional thyristor inverters. ... (Omitted) ...In addition, the advent of vector-control inverters has dramatically expanded the field of application, including those in the field of conventional DC machines.

Excerpt from Fuji Electric Journal Vol. 58, No. 11 (1985) “Power Electronics Special Feature”

higher performance and multi-functionality

As transistor inverters entered an era of widespread use, they were increasingly expected to replace the need of variable-speed drives that utilize AC motors, not only for energy-saving applications for fans and pumps, which at the time accounted for 60% of induction motors, but also because of other advantages such as providing better maintainability for DC motor drives in rolling plants, papermaking plants, and processing machinery.

- - 1985 Achieved a total production of 100,000 general-purpose inverters

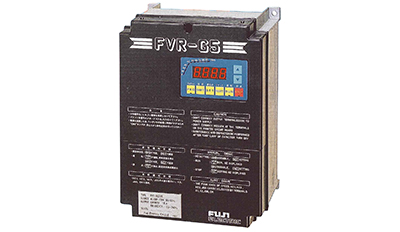

Digitalization technology for control circuits was the innovation that contributed greatly to the diversification of needs that accompanied the spread of inverter use. Until then, the output of inverters could only be adjusted analogously using dial volumes, but digitalization allowed for precise adjustment. However, the biggest advantage was that it enabled the development of control software. By improving the “intelligence” of inverters through control software, they could be programmed to operate a variety of mechanical devices, and this further expanded their application.

Digitalization technology also led to the development of vector control technology, which enabled more advanced control of AC motors through sophisticated vector calculations that allowed for rapid speed changes, response to impact loads above steady-state torque, high speed control accuracy, and wide speed control ranges. As a result, the use of variable speed AC motors, which are easy to maintain, took root in steel processing lines, where DC motors had conventionally dominated due to their ability to provide high-precision control.

- 1990 Achieved a total production of 1,000,000 general-purpose inverters

In the late 1990s, vector-control inverters evolved further by offering auto-tuning functions that enabled optimal control by automatically detecting motor characteristics, as well as miniaturization through speed sensorless vector control.

2000s and beyond: Diverging needs Premium and low-cost types

- 2002 Achieved a total production of 5,000,000 general-purpose inverters

- 2012 Achieved a total production of 10,000,000 general-purpose inverters

- 2020 Achieved a total production of 15,000,000 general-purpose inverters

General-purpose inverters have been recently expanded to various applications, and in addition to enhancing control performance, they are being required to improve energy saving, environment resistance, and preventive maintenance. ... (Omitted) ... the performance and function of general-purpose inverters have greatly improves, and their application versatility is on the increase, ranging from simple variable speed drives to machine tools and horizontal or up-down conveyance machinery.Excerpt from Fuji Electric Review Vol. 94, No. 1 (2021)

Since the 2000s, the need for inverters has been diverging, as inverters have become the standard for driving motors at variable speeds.

Premium type inverters offer high performance and multi-functionality. More specifically, they provide outstanding core performance in terms of advanced control and accuracy, as well as programming tools that allow users to customize the inverter to their specific application needs, and functions for preventing failures and predicting service life. Premium types can be used for a wide range of applications, including in the maintenance of user equipment. In contrast, according to our catalog-based sales results, the demand for compact types has been increasing due to their low cost and ability to achieve energy savings in small-capacity fan and pump applications.

Since the advent of inverters, the most effective means of achieving the core performance requirements of compactness, light weight, high control performance, high efficiency, and high reliability, which are features that have always been in demand, has been through the use of power semiconductor devices. Beginning with power transistors in the initial stages and progressing to IGBTs, MOSFETs, and other semiconductor devices in recent years, Fuji Electric has continued to work closely with its semiconductor device development departments and converter development and application departments to integrate the needs of the inverter market into the evolution of our proprietary power semiconductors. Going forward, we will take advantage of our strength as one of the world’s few manufacturers of power semiconductors to contribute to automation and energy savings with our extensive lineup of inverters for various applications in a variety of industries and fields.

Fuji Electric’s History of General-Purpose Inverters

Contribution to SDGs

Fuji Electric’s high-frequency induction furnaces, which use power electronics technology to serve as the next generation of environmentally-friendly industrial furnaces, contribute to the priority SDGs “9. Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation” and “13. Take urgent action to combat climate change and its impacts.”

Related link

Recommended

December 4,2025

July 30,2025

July 28,2025

July 7,2025