Achieving High Performance and Low Costs with One of the World’s Smallest Devices! The Ultrasonic Flowmeter—A Must-Have Tool for Energy Saving

To achieve greater energy efficiency, there is a growing need to accurately measure and manage the volume of liquids that flow through various pipes. Fuji Electric has developed a palm-sized ultrasonic flowmeter that can be installed in narrow, cluttered pipe layouts. It was thanks to the efforts of devoted flowmeter specialists that a balance between size reduction and high performance was achieved. We interviewed three employees who were involved in the development process.

Aiming for a Palm-Sized Device

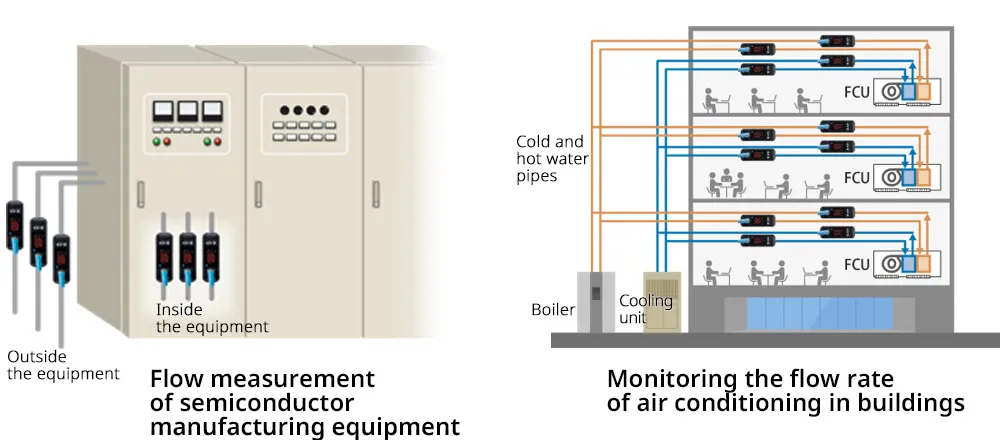

Ultrasonic flowmeters are devices used to measure the amount of liquid that flows through pipes. These devices have long been used in factory plants. In recent years, however, the range of applications has expanded. For example, they are now used to reduce costs by measuring the amount of pure water and chemicals used in semiconductor manufacturing plants, or to control the amount of heat on each floor by adjusting the amount of cold water and hot water flowing into air conditioners in buildings and offices.

With the ability to take measurements in end pipes, which had been overlooked in the past, these devices have assumed an essential role in realizing carbon neutrality and saving energy.

However, because end pipes are narrow and closely spaced, it was difficult to install existing products in many locations.

To address this issue, Fuji Electric began working on reducing the size of the ultrasonic flowmeter. The aim was to create a palm-sized device.

Never Tiring After 36 Years of Devoted Work

Efforts to develop an ultrasonic flowmeter that can be used for narrow pipes (8 mm to 32 mm in diameter) in semiconductor manufacturing plants began in June 2021.

The project leader is Mr. Kishiro of the Measuring Technology Development Department, a seasoned employee who has been with the company for 36 years. Since joining the company, he has devoted himself to the development of flowmeters. A man of few words, his deeply contemplative demeanor embodies the image of an engineer. Ms. Miyamoto, who has been working with Kishiro for 13 years, praises Kishiro as “akin to the God of flowmeters.”

“I never get tired of developing flowmeters, even after so many years. For this product, once I started thinking about how to make it smaller, I just couldn’t stop,” Kishiro laughs.

After Prototype Completion, an Unexpected Event

There were two challenges in reducing the ultrasonic flowmeter to palm size: (1) integrating two previously separate devices (the flow transmitter and the detector), and (2) simplifying the circuit to reduce the circuit board to less than a tenth of the previous area.

“Normally, it takes three years to develop a product, but because other companies were also making similar products, we were required to deliver in as soon as a year and a half,” says Kishiro. “It was difficult because we had to make new circuit boards and sensors, but the early stages of development progressed smoothly,” Kishiro reflects.

A prototype was built seven months later, in January 2022. But then, they encountered an unexpected problem. The measurement accuracy did not turn out as expected. There didn’t appear to be any performance issues with the individual parts, but when they were combined, neither the circuit board nor the sensors worked as expected.

A month passed, but no solution had been found. Kishiro instructed the team to divide the problem into pieces, so they began to investigate each part for issues.

The Accuracy Depends on Sensor Compatibility!

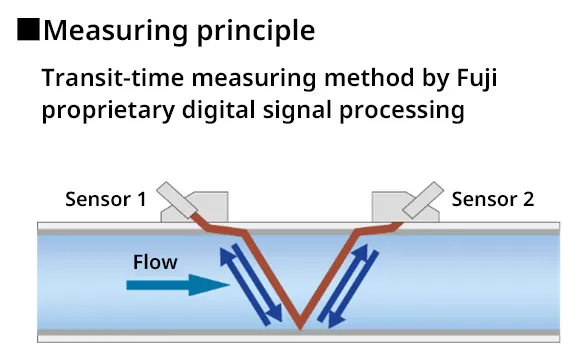

In an ultrasonic flowmeter, two sensors installed on the outside of the pipe transmit an ultrasonic pulse diagonally from the upstream and the downstream sides, and the flow rate is measured based on the time difference caused by the fluid movement.

“If the pipes are narrow, the measurable distance is shorter, making it difficult to maintain high accuracy," says Miyamoto, who was tasked with developing the sensor. They also found that the minor individual differences between the two paired sensors resulted in poor accuracy.

“Sensors have compatibility. We were able to solve the problem by measuring the characteristics of the two sensors and finding a pair that works well together,” says Miyamoto.

A Eureka Moment in the Bath

Meanwhile, Kishiro had been puzzling over another difficult problem.

A product that is a tenth of the size of existing products would retain heat. They had succeeded in reducing the power consumption to one-third by lowering the voltage to the limit. This should have worked in theory, but the heat remained. “My outlook was too optimistic,” Kishiro reflects.

One day in February, Kishiro headed home, still without a solution. It was a 30-minute walk. The cold wind stung. At home, he went straight to take a bath. Then, in the bathtub, it occurred to him that they should go ahead and add another power supply circuit.

“Adding circuits is expensive, so I had been avoiding it without much thought. But no matter which way you looked at it, adding a circuit was the best choice. I made the proposal right away the following day,” Kishiro recalls.

When the parts were modified and reassembled in June 2022, the accuracy exceeded expectations, producing some of the best results in the industry. We were also able to minimize the cost, which had been a concern.

A Sense of Personal Growth Through Involvement in the Entire Process

Having just joined the company in FY2023, Mr. Masuda was in charge of evaluating the final product performance. He was assigned to the flowmeter development team immediately after completing the training for new employees.

As a student, Masuda researched quantum optics. Regarding his decision to work for a manufacturer in a field that differs from his specialization, he explains, “Measuring instruments are indispensable in quantum optics research. Fuji Electric offers various types of measuring equipment, including flowmeters, and I thought it would be interesting to work for a company that makes things that I am familiar with.”

When he was first assigned to the development team, he had no knowledge of flowmeter circuit boards. But through repeated performance tests, he gradually gained the ability to understand a wider range of concepts.

“From designing a new circuit board to finding the causes of issues, the opportunity to be involved in the entire process left me with a sense of personal growth,” Masuda relates.

Exploring Ways of Working After Childcare Leave

In June 2024, after completing the development of the ultrasonic flowmeter, Miyamoto took maternity and childcare leave. When she returned to work ten months later, she saw things she hadn't seen before.

"When I returned to work after a long absence, I sensed that others had been helping me. Even while I was away, my superiors and colleagues were following up on my work, and their kindness really hit home.”

Development involves a lot of work that can only be done on site. However, Miyamoto now works remotely one day a week as she navigates the challenges of balancing work and childcare. Employees with children are exploring ways of working while exchanging information and consulting with each other.

“A male employee in my department is planning to take childcare leave. If there's anything I can do, I want to help,” Miyamoto relates.

No Finish Line in Research

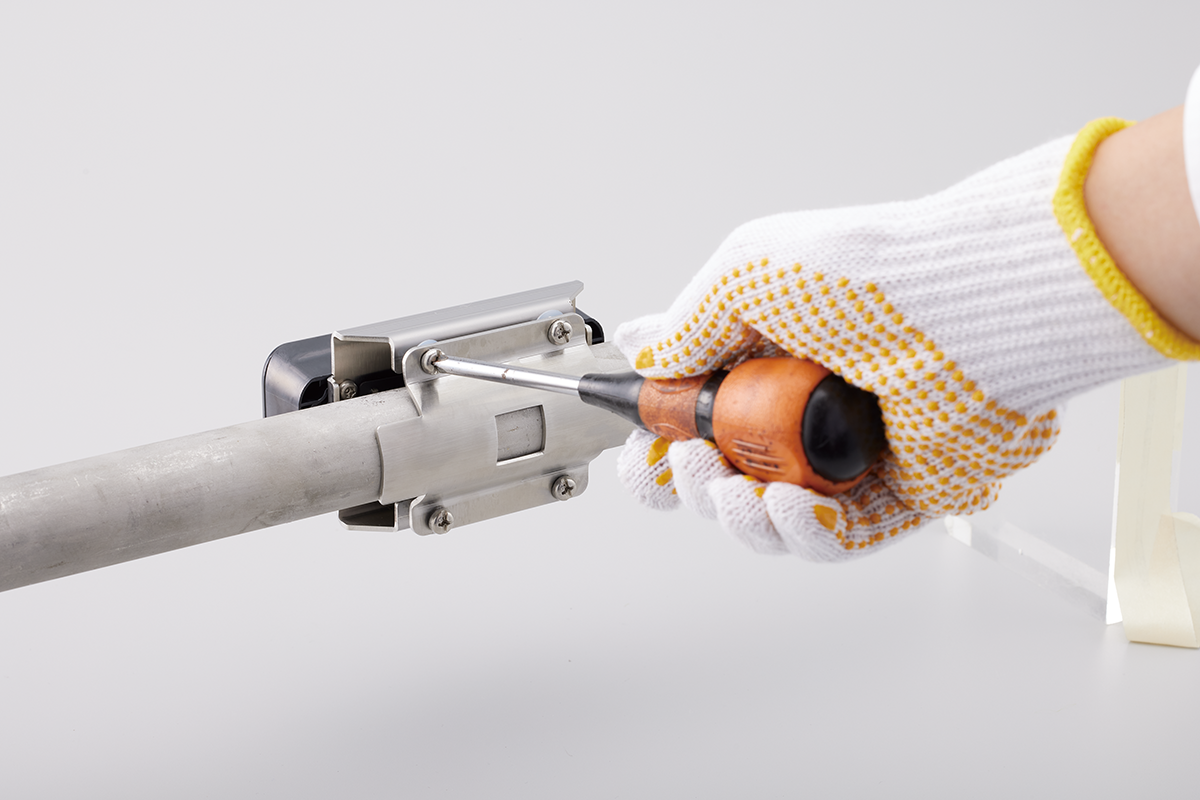

The palm-sized S-Flow ultrasonic flowmeter is easy to install. Without the need to cut the piping, anyone can attach it easily with a single screwdriver.

As the next step, the team is currently developing an ultrasonic flowmeter for the piping of air conditioning systems in buildings and offices. The new flowmeters will be equipped with Bluetooth. This will enable maintenance to be performed via wireless transmissions using tablets and other devices, eliminating the need for workers to check the ceiling pipes manually.

The team continues to push forward every day, aiming to complete development by the end of FY2025.

We asked these three employees to write messages to students and share their thoughts.

Kishiro (left), who wrote “Planning and Full Effort,” relates, “Deadlines make work challenging, but planning and full effort will be your strengths.” Miyamoto (center) wrote “Keep Thinking Together,” explaining, “The workplace is full of professionals, so when things don't go well, you can find a way by continuing to put your heads together.” Masuda (right), who wrote “Just Try,” responds, “When there is something I don’t understand initially, what I do first is to just try it out to get a sense for it.”

With 36 years of flowmeter development under his belt, Kishiro relates, “This development project taught us how compact an ultrasonic flowmeter can be. It currently stands as one of the world’s smallest devices of its kind. It's both rewarding and fun to be able to keep taking on new challenges in my work.”

There is no finish line in research. New challenges that society will face moving forward will also be resolved by the relentless inquisitiveness of specialists.

Recommended

July 30,2025

July 7,2025

July 2,2025

June 27,2025