Tracing the Roots of Our Energy and Environmental Business

History of Uninterruptible Power Supplies (UPS) (Part I)

An uninterruptible power supply (UPS) is a system that provides back-up power in the event of a power failure due to a natural disaster such as a typhoon or lightning strike, or an unexpected accident. Large-scale computers such as cloud systems have become important parts of our infrastructure that support our daily lives and businesses. Since there are many facilities where power failures can have serious and even fatal consequences, such as hospitals, broadcasting stations, and manufacturing lines, the UPS has become an essential tool to support the resilience of industry and social infrastructure.

For UPS systems that are required to be highly reliable due to their purposes, Fuji Electric has developed highly reliable products and services that meet the needs of the times in line with the advancement of power electronics. This section describes the history of uninterruptible power supplies based on the Fuji Electric Journal,* which has been introducing the latest technologies of the times for about a century since the establishment of Fuji Electric.

-

*

-

Publication started in 1924 as the Fuji Electric Journal. The journal is currently referred to as Fuji Electric Review.

1950s: The emergence of uninterruptible power supplies

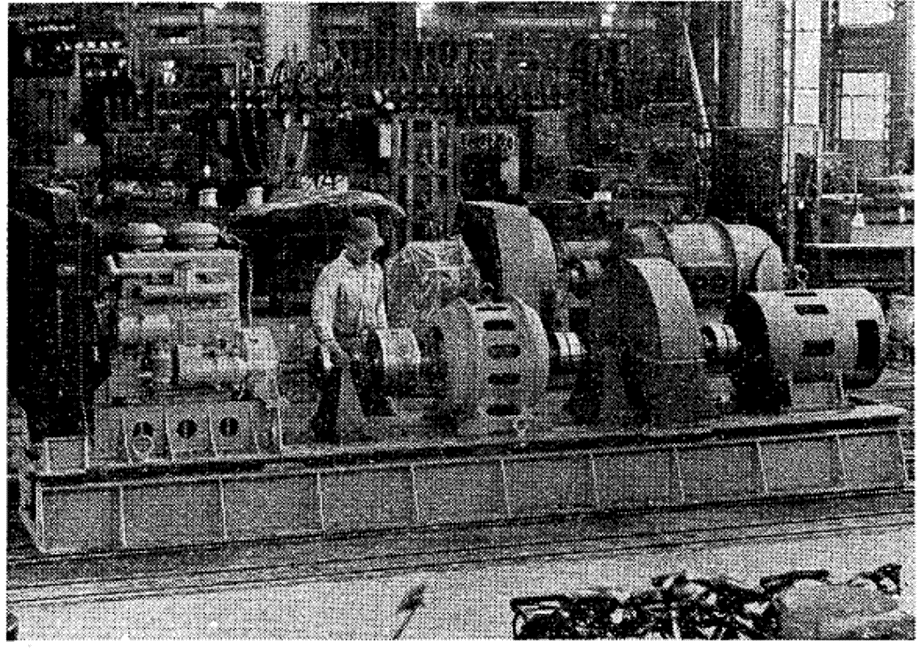

Our first research and development of uninterruptible power supplies date back to the 1950s. We completed a prototype in 1954 and exhibited it in various venues. Afterward, we continued further experiments and research and developed three types of UPSs: IG, MSG, and MIG, each of which had proven to be a success by 1955.

Conventionally, storage batteries have been used as the main power source for wired and wireless communications. However, storage batteries gradually discharge and lose voltage, regardless of whether they are used, . . . and the service life of the batteries run out, and they become waste in a few years. Batteries also require troublesome daily maintenance, such as constant adjustment of the specific gravity of the electrolyte and auxiliary charging. They also have other disadvantages, such as requiring large amounts of floor space in buildings. These issues make them difficult to use as power supply devices at unmanned stations. . . . We have been conducting experiments and research on uninterruptible power supplies since last year, and have also delivered products. . . .

Excerpt from Fuji Electric Journal Vol. 28, No. 5 (1955)

-

*

-

This citation is an English translation of the Japanese original (the same shall apply hereafter).

Taking advantage of our strength in rotating machines, which was one of our core businesses at the time, we adopted a system that used an engine which also works as an electric motor/generator. Storage batteries that were used as power supply devices for telecommunications back then fell short in terms of their service life and maintainability. However, these issues were solved by eliminating the period of power outage by storing kinetic energy through high-speed rotation of a heavy disk called a flywheel and generating electricity by inertial force during power outages. We delivered battery devices with capacities ranging from 5 to 30 kVA.

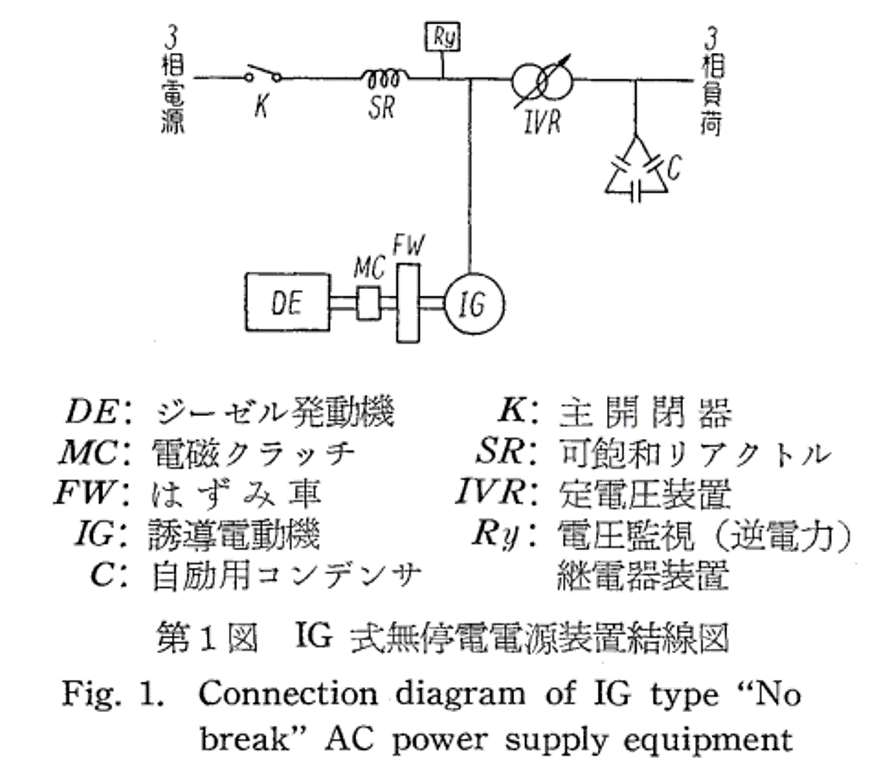

DE: Diesel Engine, K: Main switch, MC: Magnetic Clutch, SR: Saturable Reactor, FW: Flywheel, IVR: Induction Voltage Regulator, IG: Induction Generator, Ry: Reverse power monitoring relay, C: Self-excitation capacitor

1960s: Emergence of large-capacity UPS and static type for computers

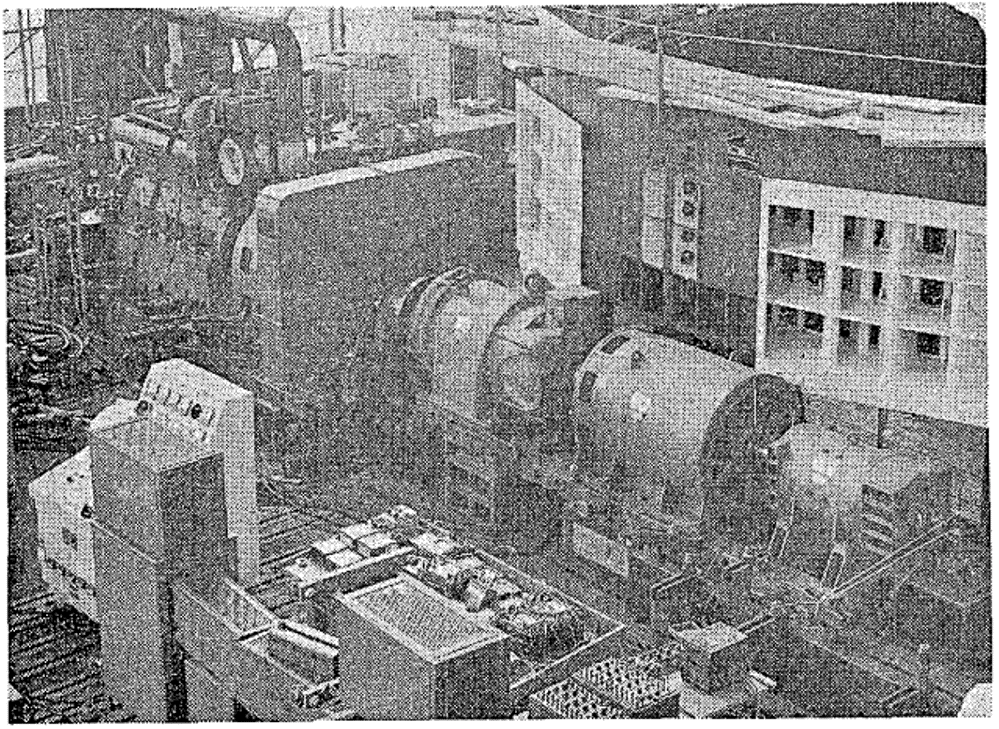

The 250 kVA uninterruptible power supply to be used as the computer power supply delivered to Nakayama Racecourse via Fujitsu is a large-capacity set of devices consisting of a diesel generator, electromagnetic clutch, spring wheel, induction motor, 200 kVA generator, and 50 kVA generator.

Excerpt from Fuji Electric Journal Vol. 40, No. 1 (1967)

In 1966, we delivered a 250 kVA large-capacity UPS to Nakayama Racecourse in Chiba. The racecourse adopted a totalizer system that Fuji Telecommunications Equipment Manufacturing (currently Fujitsu) had developed for the first time in Japan. Our high-capacity UPS was responsible for stabilizing the power supply for this system, which calculated the votes and odds for tens of thousands of betting tickets.

The uninterruptible power supply back then still used the flywheel. After our delivery to Nakayama Racecourse, we delivered the UPS to Hanshin Racecourse and Kyoto Racecourse as well. Meanwhile, we were also developing a constant-voltage constant-frequency power supply (CVCF) that used a semiconductor thyristor in the inverter section.

The development of the mushroom head thyristor element has led to the manufacturing of various large-capacity devices along with the expansion of applicable fields. . . . We examined various problems for the standardization of large-capacity three-phase self-excited inverters by actually creating prototypes of the inverters. . . . We specifically studied problems that occur when using the inverters in power supplies for variable speed operation of AC motors and UPSs.

Excerpt from Fuji Electric Journal Vol. 40, No. 1 (1967)

Computers have been improving in recent years at a remarkable speed, and the mission of power supply units is also becoming critical. The conventional electric generator type (M-G type) power supply units generate large noise and vibration, and the installation space has been restricted. Thus, constant-voltage, constant-frequency power supply units with thyristor inverters, which are compact, lightweight, and have a high degree of freedom in terms of installation location, began to attract attention.

In 1969, we developed a 200 kVA constant-voltage constant-frequency (CVCF) power supply unit with a large capacity three-phase thyristor inverter at Matsumoto Plant and delivered it as a power supply for computers at the Fujitsu Kawasaki Plant.

Related link

Recommended

October 31,2025

July 30,2025

July 28,2025

July 2,2025