Combining conflicting characteristics! “Filler dispersion technology” changes the future of materials

“Fillers,” just a few microns of powder mixed into resin. This powder greatly contributes to size reduction of motors and gas insulated switchgear (GIS).

Fuji Electric’s “filler dispersion technology” is an epoch-making material design that simultaneously satisfies two conflicting conditions: “letting heat escape while keeping electricity in.” We asked three employees about the background of the development.

“Magic powder” holding the key to equipment downsizing

Customers are increasingly telling us, “We want electric equipment to be smaller.”

However, while the “resin material” used for a lot of electric equipment has excellent insulation performance, it does not conduct heat easily. If the size of equipment is reduced while using conventional resin material, it may cause product deterioration and failure due to “heat being trapped in the equipment” and “short circuiting due to electric discharge..”

Since around 2021, Fuji Electric has been focusing on the development of “filler dispersion technology,” a technology for producing “resin materials that can freely control the way heat is transferred.”

Resin is mixed with a “powdery material” called “fillers” to adjust its properties. There are various types of materials used for “fillers.” What’s used here is ceramic powder with a grain size of 1 to 10 microns.

Why ceramic?

When you hold ceramic china and plastic in your hand, china is colder. This is because ceramic “conducts heat easily” and takes away heat from your hand. Depending on how many ceramic fillers are mixed into resin, it is possible to adjust the way electricity is conducted and the way heat is transferred.

Fuji Electric’s development team aimed to “combine the best” of resin and ceramic, which have conflicting properties.

“Degree of friendliness," as shown by the numbers

By blending fillers, it is possible to customize resin material to meet the needs of various products.

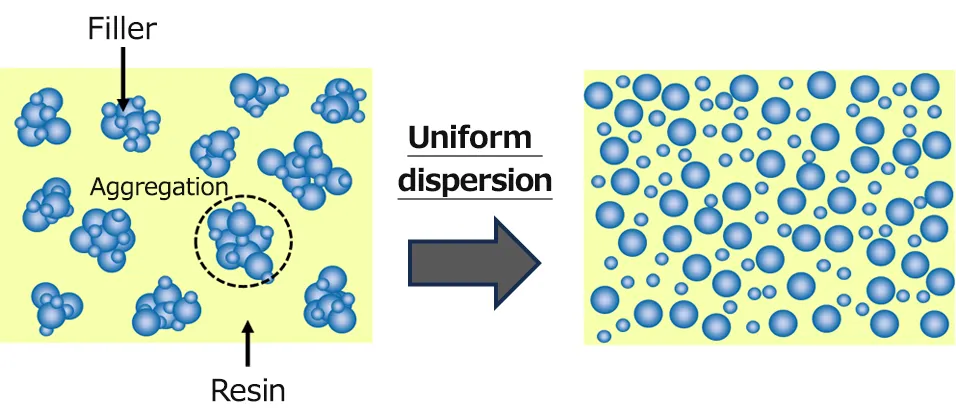

However, there is a problem in mixing resin and fillers. If a lot of fillers are added in order to increase the performance of ceramic, the performance of the resin is destroyed.

The key is the “compatibility between the resin and fillers.”

The term “ceramic” refers to dozens of substances, including glass-like substances and oxides of aluminum. Furthermore, the compatibility of the same substance with resin varies depending on the material manufacturer; therefore, there are infinite combinations.

For example, water and oil separate, but water and alcohol mix uniformly. The same is true for the relationship between resin and fillers: the better the compatibility, the more uniformly the fillers disperse and mix in the resin. As a result, more fillers can be added to the resin.

In order to establish the filler dispersion technology, it was necessary to efficiently find a combination having good compatibility among a myriad of combinations.

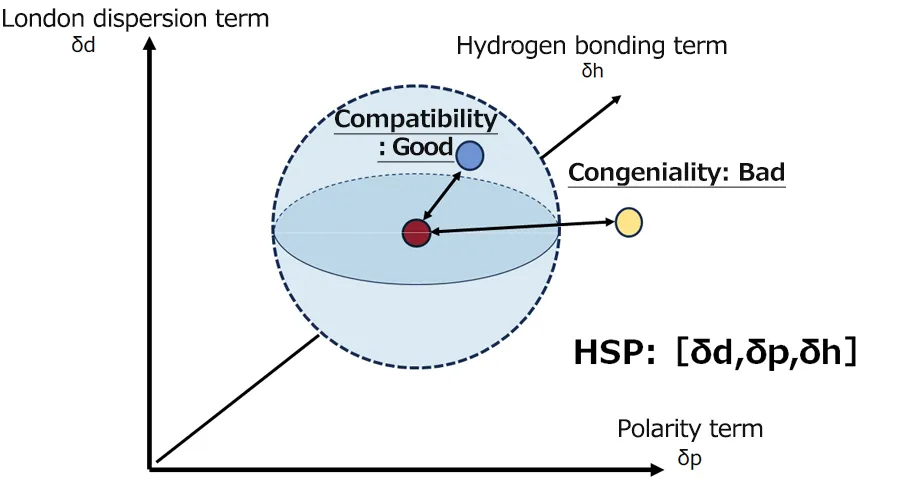

At that time, Mr. Gambe, chief of the Resin Material Group, came up with the idea of using “Hansen solubility parameters (HSPs)” to quantify the “degree of friendliness” between materials. Mr. Gambe is a veteran employee, who left a material manufacturer and joined Fuji Electric.

“Although Fuji Electric is not a material manufacturer, I felt that in order to achieve the required specifications, I would have to make a proper approach based on basic material research,” says Mr. Gambe, referring to the use of HSPs, which are often used in material research.

The most interesting part is figuring out why things went wrong

Dr. Hosaka, who joined our company in 2020, inherited the idea from the veteran, Mr. Gambe.

An HSP is like a yardstick for ensuring that materials that fall within a drawn circle, as a range of friendliness, mix well. The larger the circle range, the larger the number of compatible materials. He widened the circle range as much as possible to find an accurate value that serves as a criterion for the borderline.

It wasn’t a smooth process, but Dr. Hosaka says, “I don’t think it was a struggle. Even if things don’t go well, figuring out why things went wrong is the most interesting part.”

Dr. Hosaka used HSPs to repeatedly simulate combinations and finally derived a value that serves as a criterion for “friendliness.” This value was a number that no other company could calculate.

“The moment I got the value, something just clicked in my mind. It felt good.” (Dr. Hosaka)

Applicable to all products that use resin

This research can be applied to all products that use resin. At Fuji Electric, what products is it used in?

[Size reduction of motors]

Resin material is used as an adhesive to fix conductors in motors.

The smaller the motor, the closer the conductors are to each other and the more easily heat is trapped. As a result, the resin material is exposed to a high temperature, and insulation performance deteriorates.

To solve this problem, we blended fillers into the resin to increase the thermal conductivity (to make it easier for heat to escape), thereby suppressing the temperature rise inside the motor. We succeeded in reducing the size of a ship motor by 30%.

[Size reduction of gas insulated switchgear (GIS)]

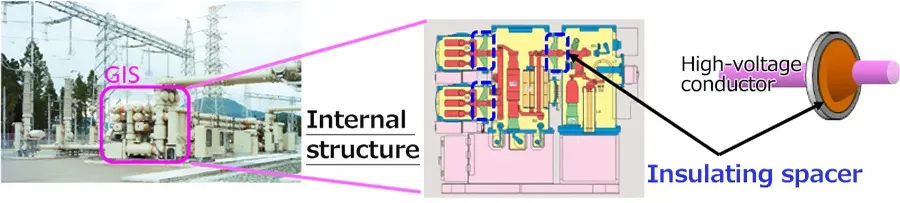

GIS is installed in substations, power transmission stations, large infrastructure facilities, etc. and acts as a switch to safely control high voltage. Inside the GIS, there is a doughnut-shaped part made of a resin material called an “insulating spacer,” which supports a high-voltage conductor.

The “insulating spacer,” which supports the conductor, has a doughnut-shaped hole, through which a high-voltage conductor passes, allowing electricity to pass easily only through the central part. The part excluding the central part is made of a resin material with high insulation performance to prevent discharge from occurring due to electric leakage to the outside. However, since it is difficult to completely prevent electric leakage with a conventional resin material, size reduction was not possible. In order to suppress the occurrence of discharge, it was necessary to control the characteristics of the resin using fillers.

Therefore, development team members blended fillers gradationally so that “near the center of the doughnut, it will store electricity more easily, and toward the outside, it will store electricity less easily.”

Thanks to this technology, the permittivity was smoothed and the occurrence of discharge, which causes short circuits, could be suppressed. We succeeded in reducing the diameter of the “insulating spacer” by 30% while maintaining the performance equivalent to that of the conventional one, which led to cost savings through the reduction of materials associated with the size reduction.

Trial and error to incorporate into products

Now we can find “friendly” material combinations through HSP simulations.

However, commercialization was complicated.

The resin material used for a motor has low viscosity like water and must be poured into minute parts. On the other hand, the resin material used for insulating spacers in GIS requires high strength and viscosity like starch syrup.

Mr. Masui, who is in charge of the manufacturing process, says, “The properties of resin and the time it takes to harden differ depending on the product. A ‘friendly’ combination does not always work well in the manufacturing process.”

The problem was, “even if we mix a material uniformly, fillers will sink down over time.” When sand is mixed with water, it sinks down after a while. The same thing happens with resin.

“The fillers are heavier than the resin material. Even if the material is mixed uniformly at first, the fillers may sink down and separate before the resin hardens.”

There are two measures to prevent settling of the fillers. One is to quickly harden the resin.

Mr. Masui says, “We can shorten the hardening time from 3 hours to 30 minutes by adding only 0.01 gram of a hardening accelerator. On the other hand, this makes it difficult to adjust the amount of blending because it may harden while being mixed.”

Another measure is to use a uniform filler size. By using a uniform filler size, the gap between fillers is reduced. This enables the uniform dispersion state to be kept for a long time and prevents settling.

Through these efforts, we are able to examine the actual production of products and find combinations that can be mass-produced by material manufacturers.

“Previously, it took a long time because we actually mixed and tested materials by trial and error repeatedly. Now that we can narrow it down to a certain extent through HSP simulations, the development speed has increased.” (Mr. Masui)

When we asked them to write messages to students, Mr. Gambe (left) said, “Quality is important any time money is involved. I think just having a ‘sense of professionalism’ is enough to do a good job.” Mr. Masui (center) said, “I hadn’t been involved in materials until I joined this company, but if you become ‘curiosity’ in something you’ve never done before, your perspective will expand.” Dr. Hosaka (right) said, “It’s ‘fun’ to find out the reasons for things. This is a job I can do with a sense of enjoyment.”

Potential expanded by the filler dispersion technology

At present, application of fillers to GIS and motors is in progress.

Regarding GIS, Fuji Electric is investing in increased production to meet growing global demand.

As several GIS units are installed in each factory or data center, demand for Fuji Electric’s GIS, which has achieved size reduction and cost savings, is increasing.

Regarding motors, Fuji Electric is currently developing ship motors. Since motors are also widely used in factories etc. and resin materials are used for all of them, the range of applications will continue to expand.

This technology is also expected to be used in the semiconductor field.

“The applications of resin materials, such as in semiconductor sealing materials and insulating substrates, are increasing. Since semiconductor devices generate heat, there is growing demand for resin materials that allow heat to escape.” (Mr. Gambe)

There is no limit to the performance that can be demanded of resin materials blended with fillers. The research team’s ingenuity continues.

Recommended

July 2,2025

October 31,2024

October 21,2024

October 2,2024