Frontline Development of New “GFM Inverter” Technology to Promote the Use of Renewable Energy

-

Power grid challenges and the need for GFM inverters

-

Cross-departmental collaboration and development team challenges

-

Aiming to develop a GFM inverter that can continue to operate even in the event of an accident

-

Lessons learned from actual machine combination testing

-

Addressing technical issues for practical application

-

Contributing to future power networks

As the use of renewable energy expands around the world, the Japanese government is promoting decarbonization by aiming to make renewable energy its primary source of electricity.However, there are some challenges to introducing renewable energy on a large scale.As one solution, there has been increasing interest in new technologies that maintain the stability of power grids.

Recently, we spoke with three team members of Fuji Electric who are involved in the development of GFM inverters (grid-forming inverters) about what it is like commercializing a cutting edge technology.

Power grid challenges and the need for GFM inverters

The electricity generated by power plants is transported to homes and factories through transmission and distribution networks called grids.Grids provide a stable supply of electricity by maintaining a constant frequency while balancing supply and demand.

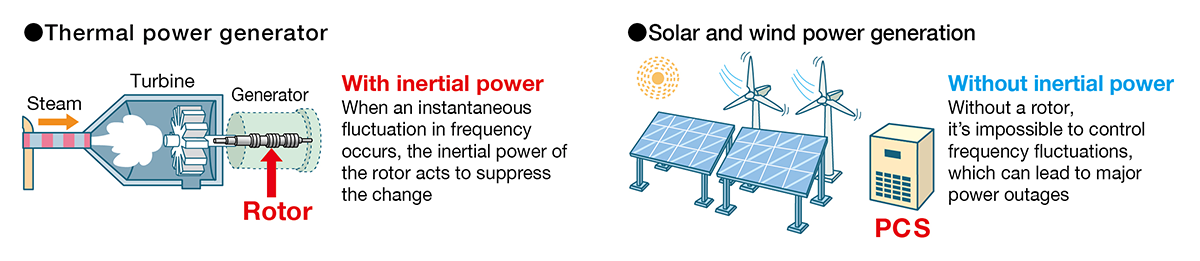

Large-scale generators, such as those at thermal and hydroelectric power plants, have been supporting grids and using their “inertial power” generated by rotational force to keep frequencies constant.However, there is no inertial power in currently available renewable energy generation.If a large amount of electricity generated by solar or wind power is fed directly into a grid, the frequency will become unstable, and in a worst case scenario, it could cause a large-scale power outage.

In order to pave the way for decarbonization, it was necessary to devise a way to make stable use of inertia-free renewable energy generation in grids.

Mr. Uemura of the R&D Department had been investigating technologies to deal with reduced inertial power. He said that when he found an overseas paper describing GFM inverters, he immediately thought, “This is it!”

According to our findings, Fuji Electric has been working on the development of a GFM inverter since the second half of the 2010s.GFM inverters use control software to mimic the characteristics of synchronous generator.They aim to contribute to the improvement of renewable energy utilization rates by supplying inertial power in the same way as generators and by stabilizing grid frequency.

The photo shows a storage battery PCS for existing products.

Cross-departmental collaboration and development team challenges

Mr. Koshiba is in charge of sales and marketing and has a graduate degree in science. His job entails identifying customer needs and disseminating information within the company.Since specialized knowledge is often required in the sales field, he says that what he learned in graduate school has helped him.

He said, “Our GFM inverter is currently a prototype for demonstration purposes, not a mass-produced product, so customers are eager to try out different things.Therefore, naturally, they have very detailed requests.It is my job to coordinate these requests so that they can be fulfilled.When the requests involve not only technical requirements but also price and delivery time, this is where sales comes into play!”

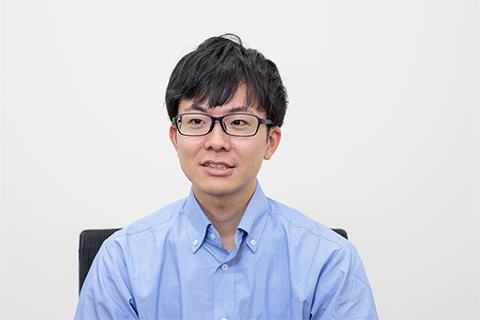

Mr. Oka of the Power & Energy Management Department uses the information he receives from Mr. Koshiba to create specifications for the commercialization of the GFM inverter.He joined the company after completing his master’s degree and is now in his third year. He is currently in charge of coordinating technical departments.

He remarked, “I organize technical issues and consult with appropriate departments, such as the design and R&D departments.The design, manufacturing, and testing departments are responsible for the details, but to achieve commercialization, it is necessary to coordinate the entire process.”

Mr. Uemura is a mid-level engineer with a Ph.D. who is in charge of developing and improving core technologies.He said, “Although there are still issues to be addressed, we are diligently working on this project because it is highly significant for realizing a decarbonized society.”

Aiming to develop a GFM inverter that can continue to operate even in the event of an accident

GFM inverter development is based on the power electronics technology that Fuji Electric has cultivated over many years.Mr. Koshiba commented, “Our major strength is that we have the technological capability to develop everything from inverter hardware to control software consistently in-house.”

One of the important technical challenges in the development of a GFM inverter is to improve the Fault Ride Through (FRT) capability.

Mr. Uemura remarked,“We aim to develop a GFM inverter that can continue operation even when there are problems such as frequency or voltage fluctuations. We want to do this by leveraging our proprietary over current suppression function (see Note) for GFM inverters.If development is successful, it will not only give Fuji Electric’s product a competitive edge, but will also contribute to the stabilization of power grids where GFM inverters are installed.”

-

(Note)

over current suppression function = A technology that regulates the amount of current to prevent internal equipment from burning out due to excessive current flow -

Lessons learned from actual machine combination testing

When testing its operation under accident conditions, the team encountered an unexpected difficulty.The final day of three-week long testing was just three days away.

Testing was conducted under extremely severe conditions, in which the voltage on the grid side dropped to zero.It was a long awaited test, but the inverter,

which was supposed to work in the design phase, did not work for some reason.Mr. Uemura and Mr. Koshiba came to the site of actual equipment combination testing, saying, “This is the big day.”When Mr. Uemura checked the situation, he found that the cause of the inverter not working was that the circuit breaker on the grid-connected panel had tripped.We immediately worked with system designers and testers to overcome the problem.

“We learned a big lesson that it is necessary to make the inverter work as a component of the entire system in combination with the grid-connected panel and monitoring and operation panel, rather than as a stand-alone unit.” (Mr. Uemura)

Addressing technical issues for practical application

There is one more challenge for the grid-oriented GFM inverter.The GFM inverter itself can continue to operate even in the event of a power failure, but under current rules, it needs to shut down for safety purposes when an upper-level system has a power failure.

One of the features of Fuji Electric’s research and development is its extensive testing environment using actual equipment. To address an issue such as this, the development team repeatedly conducts detailed simulations and tests using actual equipment.Mr. Oka said, “By taking both theoretical and practical approaches, we are developing more reliable products.”

“Building ongoing relationships with customers is important. Above all else, it is important to take care of your health.” (Mr. Koshiba)

“You’ll never know the outcome unless you try, so just give it a go!” (Mr. Uemura)

“As I am only in my third year at the company, I approach everything as a challenge!” (Mr. Oka)

Contributing to future power networks

Mr. Uemura remarked, “At Fuji Electric, our business activities contribute to solving social issues.Therefore, tackling the issues at hand directly contributes to society.”

The challenge facing these three team members is the practical application of GFM inverters.If successful, it will promote the introduction of renewable energy and contribute significantly to the realization of a decarbonized society.

Recommended

December 4,2025

October 31,2025

July 30,2025

July 28,2025