Tracing the Roots of Our Energy and Environment Businesses

History of General-Purpose Inverters (Part 1)

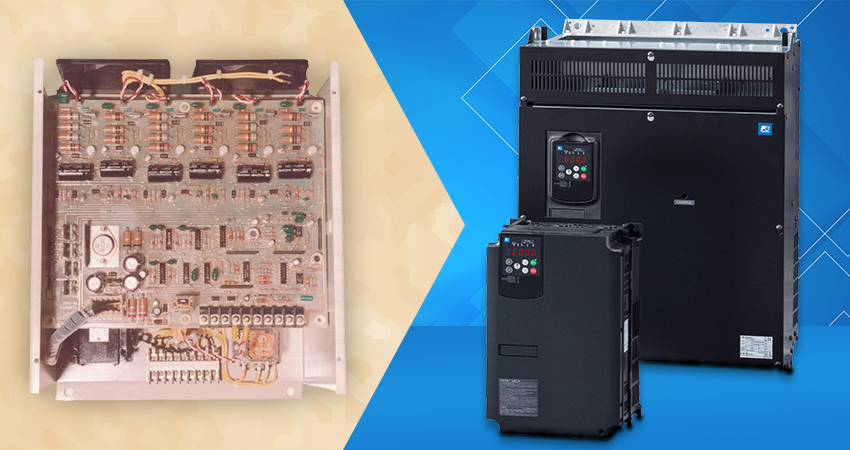

Inverters are devices that control the rotational speed of motors. Throughout the years, they have become indispensable for industrial infrastructure, as their need continues to expand in the automation of various types of machinery and equipment, including energy-saving fans and pumps used in plants and factories, elevators, cranes, conveyors, and machine tools. Inverters enable motors to operate with minimal energy by controlling the required number of revolutions. Therefore, they typify products that contribute to energy conservation, and thus help to reduce CO2 emissions. Fuji Electric launched its lineup of FRENIC5000 Series general-purpose inverters in 1976, and since then has produced more than 18 million general-purpose inverters (as of March 2023) in total. In this article, we will discuss how general-purpose inverters were invented and how they have evolved to meet a variety of market needs. In particular, we will unravel the history of inverters from past editions of Fuji Electric Review*, a publication that has continued to introduce the latest technologies of each generation for nearly 100 years since Fuji Electric’s founding.

-

*

-

Publication started in 1924 as the Fuji Electric Journal. The journal is currently referred to as Fuji Electric Review.

1960s: The advent of inverters

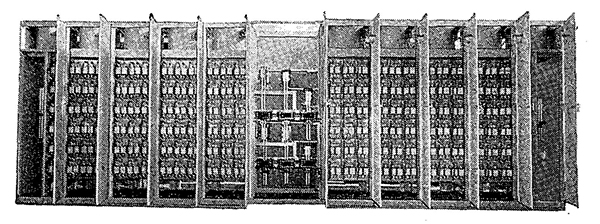

Inverters first appeared as a product in the Fuji Electric Review as far back as 1966. Prior to that, mercury rectifiers were used to control the rotational speed of motors. In the 1950s, we started supplying many of these rectifiers to steel rolling mills. At the same time, it was recognized that the DC motors used in these applications had the advantage of making it easy to control rotational speed. On the other hand, they also had the disadvantage of requiring regular maintenance due to brush wear and other problems.

(Omitted) ... We delivered many single-phase inverters using thyristors to various electric power companies, Tokuyama Soda, Ube Industries, and other customers. In addition, we manufactured a 200 V 50 Hz 3 kVA three-phase inverter for driving a water-lifting pump for the Tokyo Metropolitan Government Bureau of Waterworks.

Excerpt from Fuji Electric Journal Vol. 39, No. 1 (1966)

-

*

-

This citation is an English translation of the Japanese original (the same shall apply hereafter).

The development of thyristors led to some major changes in the field of power conversion. As a result, inverters capable of controlling AC output to any desired frequency, thanks to their excellent switching characteristics, started to be increasingly used in AC motor control applications. Since AC motors do not use brushes, they offer significant advantages in terms of maintenance, especially during continuous operation. This encouraged the widespread use of AC motors with inverters in industrial applications.

The demand for thyristor inverters has been increasing in applications that require AC stabilized power supplies for computers and various measuring instruments. As a result, they are now being used extensively in place of conventional rotating machines. In addition, inverters used in variable speed power supplies for electric motors, such as those used with spinning machines, have become standardized in response to the demand. ... (Omitted) ... We have been delivering a large number of motor-operated systems that utilize self-exciting inverters, mainly for use in spinning plants.

Excerpt from Fuji Electric Journal Vol. 44, No. 1 (1971)

At that time, the textile industry was Japan’s main industry. Since sagging or cutting of materials in the production process could result in quality defects, it was necessary to synchronize the rotation of multiple motors, and thyristor inverters were used to control these motors. Computer applications leveraged the steady output of inverter control to stabilize power, leading to the subsequent development of uninterruptible power systems. Inverter technology using high-speed thyristors dramatically expanded the possibilities of variable speed operations.

Thyristor inverters had been used in a wide range of applications to control the operation of AC motors. However, it was difficult to obtain economical benefits at small capacities, so they were mainly used with motors within certain capacities or for applications where a single inverter was used to control many motors simultaneously.

1970s: From oil shocks to energy conservation

In the 1970s, there were two oil shocks that wreaked havoc on the world economy. Industries in Japan also experienced inflation caused by soaring oil prices and this led to economic downturn. As a result, stabilizing the energy supply became a top priority. This experience created widespread interest in “energy conservation” in Japan, which was originally grounded in the culture of “mottainai,” a nuanced word meaning “waste due to excess consumption.” To this day, this concept has encouraged energy conservation both in businesses and at home.

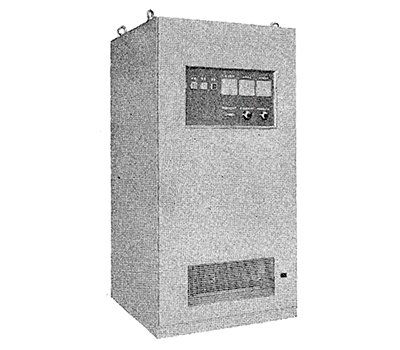

By the mid-1970s, our thyristor inverter product lineup had expanded to capacities of 12.5 kVA to 200 kVA, and demand had grown to more than a hundred units per year, especially in field of textile applications. Thyristor inverters made it possible to operate motors with greater control, leading to expectations for smaller capacities and lower costs in order to apply them to a wider range of needs.

AC variable-speed drives are increasingly becoming the mainstay of today’s variable-speed drives, and this trend inspired various developments and improvements in the past year. ... (Omitted) ... We developed a lineup of voltage-controlled inverters (FRENIC5000) featuring transistors that offer economical advantages at small capacities from 2 kVA to 12.5 kVA, and responded to demand from the textile industry through our proprietary instantaneous power outage solutions.

Excerpt from Fuji Electric Journal Vol. 50, No. 1 (1977)

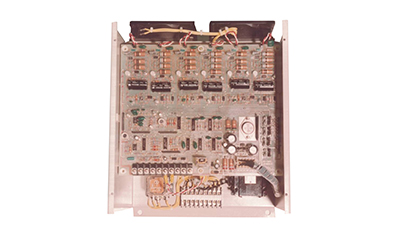

In 1976, we introduced our FRENIC5000 Series as a lineup that utilizes power transistors and offers the benefits of small capacities and lower costs. Inverters use semiconductor switching circuits to control output voltages and frequencies. Shorter switching cycles (i.e., high frequencies) reduce current capacitance and capacitor capacities, resulting in miniaturization. The FRENIC5000 Series successfully reduced the size of inverters by utilizing transistors in semiconductor elements to achieve faster switching than thyristors. This lineup of products met the need for lower costs, something that was highly anticipated, especially in small capacities. The use of transistors to develop a series of small-capacity inverters was a major step forward in what could be regarded as the advent of general-purpose inverters.

The history of transistor inverters has been characterized by expansion of capacity, higher performance, and lower costs. Currently, their performance relative to cost has been well-received, allowing them to usher in an era of widespread use. Inverters are necessary for efficiently changing the speed of AC motors steplessly. Thyristor inverters have been conventionally a popular choice, but their small capacity range has made practical use economically difficult. However, the development of power transistors for high power applications and the development of economical inverters that utilize these power transistors have contributed to the creation of variable-speed drives in the field of small-capacity electric motors.

Excerpt from Fuji Electric Journal Vol. 58, No. 4 (1985) “Outlook for Transistor Inverters” (partial summary)

After the oil shocks, various industrial sectors began to consider energy conservation. Against this backdrop, FRENIC5000 Series inverters met the need for energy savings by driving fans, blowers, and pumps at variable speeds. In addition to their compact and lightweight functional design, they gained popularity as general-purpose inverters that anyone can operate, thanks to their safety circuits and automatic operation circuits.

(Continued)

Related link

Recommended

July 30,2025

July 28,2025

July 7,2025

July 2,2025