Changes of uninterruptible power system

Recommendation of preventive maintenance

reventive maintenance is required to maintain characteristics and performances of UPS.

An UPS is composed with various electronic and electrical parts, and its performance is demonstrated only when all components work properly. Since some of component parts become deteriorated under particular environmental or operational circumstances, a planned parts replacement is necessary.

Example of periodical replacement parts * Medium- to Large-capacity UPS rated 10kVA or more

Replacement period differs depending on UPS series.

■ Parts for periodic replacement

| Replacement Cycle | Part | Impact of failure | External shape of the parts (example) |

|---|---|---|---|

| 3–5 years | Cooling fan | Abnormality of a fan causes an increase of inside temperature and a failure stop of an UPS. |  |

| 5 years | Magnetic contactor | A grease solidification at moving parts causes a malfunction and errors of uninterruptable switching and operation during a power outage. |  |

| 7.5 years | Control power | If the control power becomes abnormal, the unit becomes uncontrollable and the UPS will fail and stop. |  |

| Relay unit Timer Relay |

Coil breakage caused by constant excitation and contact failure caused by oxidation and corrosion will lead sequence control errors. |  |

|

| Electrolytic capacitor | Abnormal destructive puncture due to drop of internal insulation resistance and/or gradual lowering of the capacitance will occur. If abnormal destruction occurs, it leads to DC short circuit and the UPS will fail and stop. |  |

|

| Surge absorber | The role of surge absorbers is to prevent intrusion of a lighting surge by releasing it to the ground. There is a risk of wire breakage by corrosion due to surge or moisture absorption in the past. |  |

|

| Fuse | An electric current is always flowing through a fuse, and it would cause an aging degradation of internal elements. Also, there is a risk of self-fusion in the end. |  |

■ Example of parts without periodical replacement

| Replacement Cycle | Part | Impact of the failure | External shape of the parts (example) |

|---|---|---|---|

15 years |

Controller PCB |

If failure has occurred in a part/component, the UPS will fail and stop. At the time of failure, the bad part/component is replaced. |

|

| Breaker |  |

||

Semiconductor element |

|

||

AC capacitor |

|

||

By category |

Battery | When a battery has failed, the UPS will stop during a power outage. MSE-type: 7–9 years |

|

Battery instant discharge diagnosis device

(BSC)

We provide a speedy diagnosis while the battery is being charged.

- We provide a diagnosis service while the equipment is in operation.

- As the diagnosis is made by short-time discharge (0.5–1.5 sec/1–3C discharge) characteristics:

- Individual degradation or failure can be detected even from many batteries are connected.

- We can diagnose about 400 units of batteries in a day.

- As the diagnosis and verification are made by direct discharging, there is no need for concern even during a power outage.

- As the amount of discharge for the diagnosis is less than 0.1%, there is no need for concern over capacity decrease.

- Our professionals would provide you the diagnosis results including an overall assessment on the spot.

- Diagnosis services provided by a qualified person for battery maintenance are safe and certain.

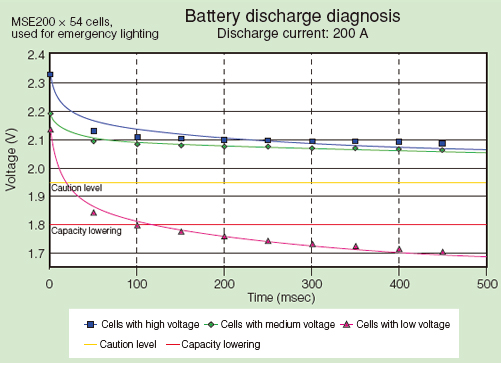

● Discharge characteristics

Perform a discharge test of all cells, and you can identify the cell with the largest voltage drop, cells of average characteristics and the cell with the smallest voltage drop. (Cells of reduced capacity have significant voltage drops.)

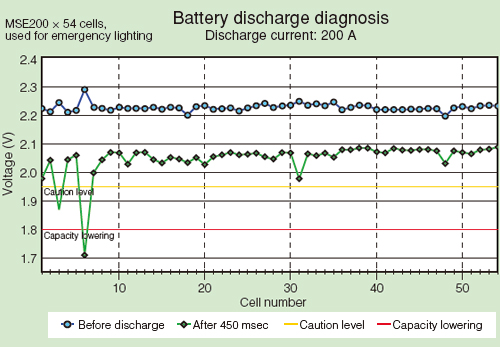

● Voltage graph of all cells

You can check the voltage distribution of all cells by plotting the data on a graph with lines drawn for an attention level and a capacity reduction level defined from the BSC measurement data vs. capacity test.

- As a basis of judgment over the Upgrade timing of batteries that are close to end of life

- As a reasoning data for good cell selection in life-prolonging treatment

- As a detection tool for early deterioration and/or bad cells

- As a regular inspection tool of battery systems

Battery capacity 20–3000 AH

(support 5000 series for 600 AH or less)

Manufacturer does not matter.

Small batteries for mini UPS and dry batteries are not supported.

| Item | Specifications |

| Battery | Voltage 1, 2, 4, 6, 8, 12 V |

|---|---|

| Discharge | Current 20–3000 A, arbitrary setting with 1 A step |

| Data file | 250 cells/file |

| Memory card | Compact flash type 1 unit |

| Communication | RS-232C 1 port |

| Display | LCD 40 digit × 4 lines, with backlight |

| Measurement accuracy | Full scale ±1% in each range |

| Internal resistance | Measurable |

| Drive voltage | DC12 V (battery drive) |

| Drive hours | 2 hours or more (after being fully charged for 15 min) |

| Temp/Humid. | 0 to 35°C, 20% to 80% |

| Weight | 4.0 kg (BSC5000i) |

Unit batteries (36, 46 V) are also supported.

BSC4800m