- Oil-immersed transformers

- Molded transformers

Changes of Oil-immersed transformers

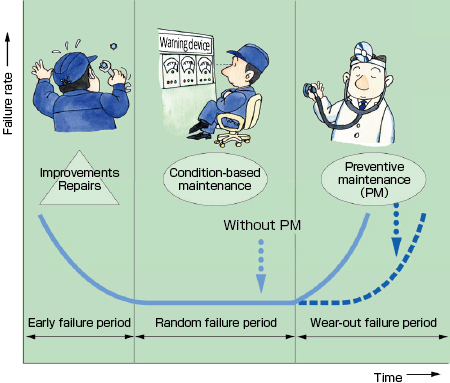

Recommendation of preventive maintenance

After years of operation, an oil-immersed transformer reaches its end of life. The failure rate of oil-immersed transformers tend to become high after 15 years of operation. Even though the appearance is fairly good, there are possibilities of dangerous conditions.

Benefits of preventive maintenance

- Preventive Maintenance means “preventive action against failure occurrence” and is abbreviated as PM.

It is a particularly important type of maintenance. - This “preventive maintenance” exerts its power effectively during the “wear-out failure period” in the bathtub curve.

What you can expect from PM:

– Accident prevention – Prevention of aging degradation – Extension of life span

Recommended replacement time of parts

Japan Electrical Manufacturers’ Association (JEMA) and Electric Technology Research Association recommend accessories/parts replacement to prolong transformer life. Please study it in conjunction with your plan of transformer inspection.

| Accessory name | Recommended replacement time | Requirement of power-off |

|---|---|---|

| Dial thermometer | Every 10 years | Yes |

| Pressure gauge | Every 15 years | Yes |

| Oil gauge | Every 15 years | Yes |

| Pressure release plate | Every 15 years | Yes |

| Bushing | Every 15 years | Yes |

| All sorts of gaskets | Every 10 to 15 years | Yes |