Changes of Oil-immersed transformers

Which generation does your equipment belong to?

Recommendation of Upgrade

Upgrade

Dissolved gas analysis (DGA) for oil-filled transformers and testing of insulating oil properties

Among equipment in substations, the percentage of aging and deteriorated devices continues to increase. Noticing deterioration conditions of aging devices and managing failure spot became important for maintaining and also for improving a reliability of power supply.

Internal faults and the degree of aging deterioration of oil-filled transformers can be determined by analyzing their insulating oil.

1.Dissolved gas analysis

Inside an oil-filled transformer, localized overheating and discharge causes thermal breakdown of the insulating oil and insulation materials, and the decomposed gas that is generated gets dissolved into the insulating oil. Dissolved gas analysis is a method of diagnosing the presence or absence of internal faults in the transformer by sampling and analyzing the concentrations of the gases dissolved in the insulating oil.

Dissolved gas analysis

-

Dissolved gas volume and criteria for determining deterioration

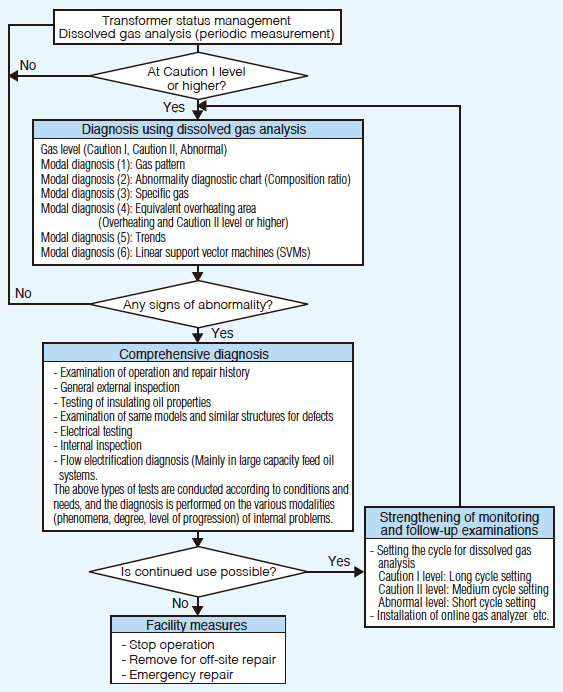

Diagnosis flowchart of maintenance management using dissolved gas analysis

Examples of report details

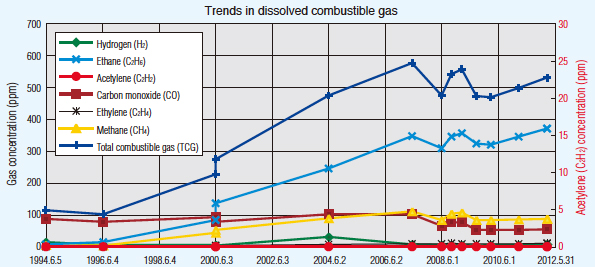

1. Trends in dissolved gas

Determination criteria

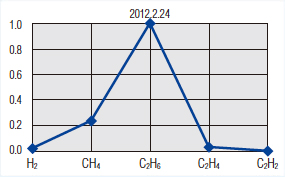

2. Gas pattern

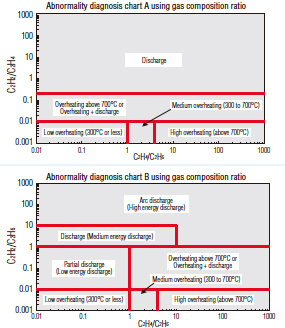

3. Abnormality diagnosis chart (Composition ratio)

4. Specific gas

2.Insulating oil property testing services

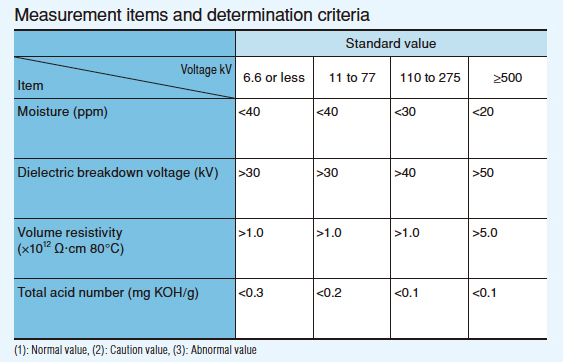

This is a method for diagnosing the health of insulation properties achieved by managing the moisture content, insulation breakdown voltage, total acid number, and volume resistivity in order to determine the deterioration level of insulating oil during operation.

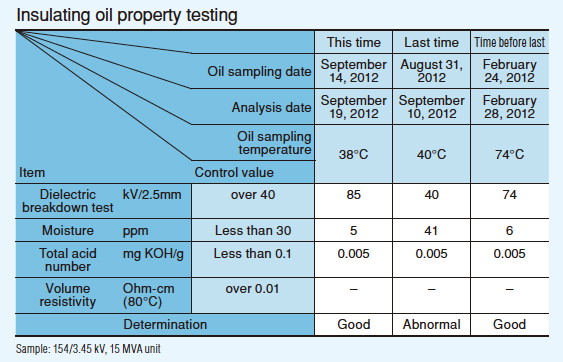

Insulating oil property testing

Examples of report details

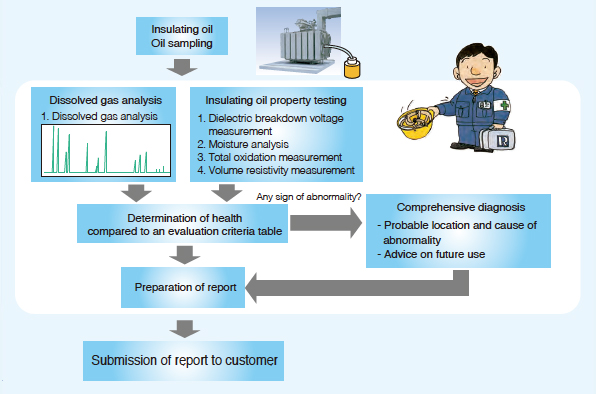

Steps of insulating oil diagnosis for oil-filled transformers

Related link

Service Solution