Changes of AC Drives (Medium voltage)

Recommendation of preventive maintenance

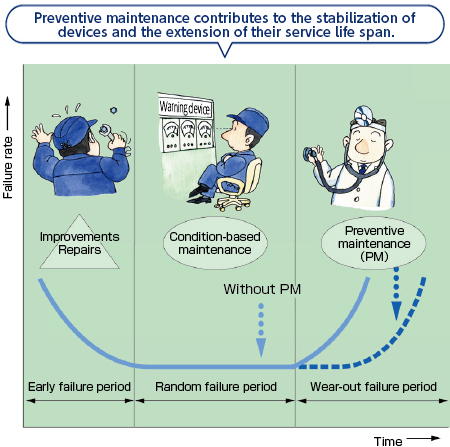

Equipment maintenance can be divided into breakdown maintenance and preventive maintenance.

Breakdown maintenance repairs the equipment after a failure occurs while preventive maintenance prevents failures from occurring beforehand through planned checks and parts replacement.

Preventive maintenance is required for the stable operation of equipment.

Benefits of preventive maintenance

- ● Reduces failure rate

- ● Maintains reliability

- ● Maintains performance and functions

- ● Maintains safety

- ● Extends equipment life

Perform preventive maintenance

1. Create a long-term maintenance plan

Inspection plan, parts replacement plan and plan of Upgrade timing

2. Perform an inspection

Perform patrol inspection, regular inspection and detailed inspection

3. Replace parts

Replace life-limited parts and replace wear-consumable parts

4. Perform diagnosis

Equipment environment, physical degradation, social lifespan, spares management and maintenance history