June 2020 Fuji Electric achieved the milestone of producing its 100,000th molded transformer "MOLTRA." To commemorate this milestone, three veteran employees, who have known everything about the molded transformer from the product’s very beginnings, came together for a roundtable discussion to reminiscence on the development project. They discussed the difficult times the developers faced until the first final product was completed, as well as their uncompromising insistence on performance and reliability. They also talked about Fuji Electric’s aspirations, which have remained unchanged for over 40 years.

Worked on the MOLTRA

development engineering.

Highly knowledgeable about the

early days of the productʼs

development.

development engineering.

Highly knowledgeable about the

early days of the productʼs

development.

Hiroshi Moriya

CE Section I, CE Department, CE Division, Chiba Factory (MOLTRA Dojo Instructor)

Contributed to expanding sales

of MOLTRAs in the equipment

sales division.

of MOLTRAs in the equipment

sales division.

Ryuzo Enta

Advisor, Tokyo Sales Office, Hokuriku Electric Co., Ltd.

Still on the frontline, driving new

technological development for MOLTRA.

technological development for MOLTRA.

Tetsumi Takano

Chief Expert, Electrical Energy Technology Research Department, Energy Technology Research Center, Advanced Technology Laboratory, Corporate R&D Headquarters

-

*

-

Departments and titles are current as of the time of the interview.

First encounters with Siemensʼ technology and the trial and error that led to the development of the first final product.

Before talking about the development of MOLTRA, we need to touch on the foundation of Fuji Electric.

Fuji Electric came into being in 1923 through a capital and technological partnership between Japanese company, Furukawa Electric, and Siemens of Germany. The new companyʼs name was created by combining the “Fu” of “Furukawa” with “Ji,” which was the first part of the name “Siemens” as it is pronounced in German. In fact, the company logo used until 1978 was an amalgamation of the letters, “f” and “s.”

There is a reason this article starts with this topic. It is because Siemensʼ presence was highly significant in the development of Fuji Electricʼs molded transformer. At the heart of MOLTRA is the technology for molding the coils with resin. This was precisely what Siemens was making. Moriya, who knows the most about those times, reminisces.

Moriya: The technology for molding coils with resin was first initiated in Europe. There was an expectation that if the characteristic resulting from that technology, namely that it did not catch fire easily, could compensate for the shortcomings of oil-immersed and dry-type transformers, it would sell in Japan as well.

When our people traveled to Siemens and showed the Siemens people a paper that summed up our resin molding and curing technologies, they showed our people their technologies. We have sublimated and fused the two companiesʼ technologies together to create the current molded transformer.

Takano was his own recollections about the research conducted at that time.

Takano: At that time, Fuji Electricʼs research papers on resins were leading the industry. I often wondered, “How far will they go?”

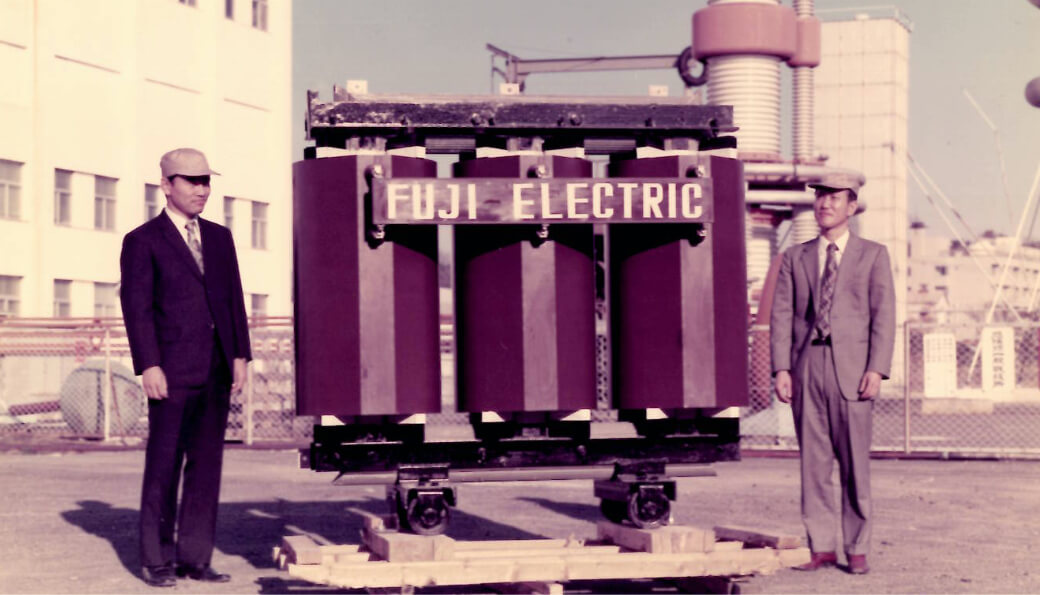

However, even if we were able to learn about technologies from overseas, we did not have the know-how or equipment to actually make the products. The road to perfecting the product was one of much trial and error.

Moriya: We had no manufacturing equipment, so what we did instead was, we turned a bicycle upside-down and used the pedals to coil the wire, and we also used the spinning wheels. The materials that were used were things like aluminum foil and cling wrap from the kitchen, just to have something tangible to show.

Takano: I think the developers struggled a great deal with the resin. Plastic might look stable, but if there is some kind of structural element inside, like aluminum, it breaks very easily. There was a lot of trial and error regarding how strong a resin to use and what conditions it should be cured under to make it last for 30 years.

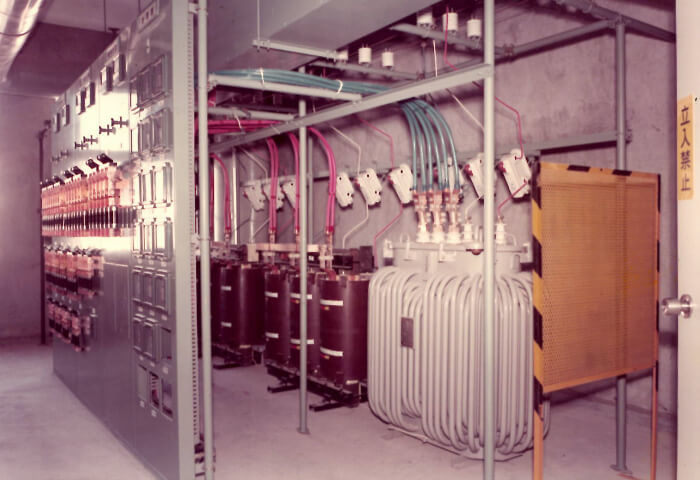

After a very rough journey, finally, in 1970, the first prototype was delivered to one of Fuji Electricʼs own research facilities. It underwent multiple modifications before it was launched for sale in 1974. The first final product was delivered to a customer in 1975. It had been 14 years since development first began.

Always thinking from the customer’s perspective, working with steadfast conviction to refine the reliability of the product.

The biggest selling point of Fuji Electric MOLTRA was that, because it did not use oil, it was safe. Unlike oil-immersed transformers, molded transformers have excellent protection against accidents, and partial electrical discharge almost never happens. These strengths were also offered a powerful argument for marketing the product to customers. The product started to come into wide use at public facilities and hospitals, but to get customers to understand the definite safety of the product, the other thing we stressed, as well as the manufacture, was having the customers actually be present to witness the testing. Enta, who was on the frontline of selling MOLTRA, looks back on that time.

Enta: By having the customers present at the factory to show them exactly what we were making, we demonstrated the safety and security of the product. It is still the case today, but even from those days, I am sure there were a considerable number of tests witnessed by the customers who ordered the product.

Moriya: After we finished our own testing and inspection, we would invite the customer in to the factory, and we would perform again whatever tests the customer wanted. The salespeople in particular were very proactive in bringing the customers to the factory and we created more opportunities for them to come and see the product. The factory's engineers and the sales reps would also often go around to the customers together, taking miniature models of the transformer with them.

That kind of attitude is evidence of the DNA that has been firmly implanted in every person at Fuji Electric, that of making products from the customer’s perspective.

Takano: After MOLTRAs were delivered to the customers, we would also go and see them in action and diagnose whether they would still function properly into the future. In this way, we could make the customers understand that it would last for many years. Some people say that, while Fuji Electricʼs products are good, they are a bit costly, but conversely, there are others who say that they are actually inexpensive for the performance they offer. We used all these different opinions as encouragement.

Moriya: I do think that there is a strong culture of thinking from the customerʼs perspective. In some cases, the salespeople would stand in the customerʼs shoes and make strong demands of the factory.

Untiring insistence on substantive performance and reliability.This is what has made the achievement of 100,000 units possible.

ʻWhy has MOLTRA been able to achieve this milestone of 100,000 units?ʼ

This roundtable discussion gave us a glimpse of the reasons for this from a variety of viewpoints.

One is the insistence on performance. There is also Fuji Electricʼs insulation technology, which it has continued to refine from a strong desire to carrying through with its original aims.

Moriya: One thing was the technology for molding in a vacuum using metal molds. When there is air left inside, it will eventually lead to destruction of the insulation. We absolutely wanted to prevent that, so right from the start, we used metal molds in a vacuum. We were absolutely insistent on that, and I believe that this technology will continue to be the mainstream.

Takano: There is almost no partial electrical discharge with MOLTRA. I think that was an extremely point in its favor. The fact that we would not compromise on that point could be described as a great thing…although some might also call it stubborn.

Takano also gave us this tidbit.

Takano: There was once a time when Fuji Electric made electrical appliances. The washing machines we used to make about 40 years ago were vertical-type washers. When all the other companies were marketing horizontal-type washers, we thought that the vertical type was better at cleaning the clothes because it would be better to rotate the clothes in a vertical direction to beat the dirt out of them. That kind of thing shows that stubborn streak. Even from way back then.

Another reason for the milestone of 100,000 units is the insistence on reliability.

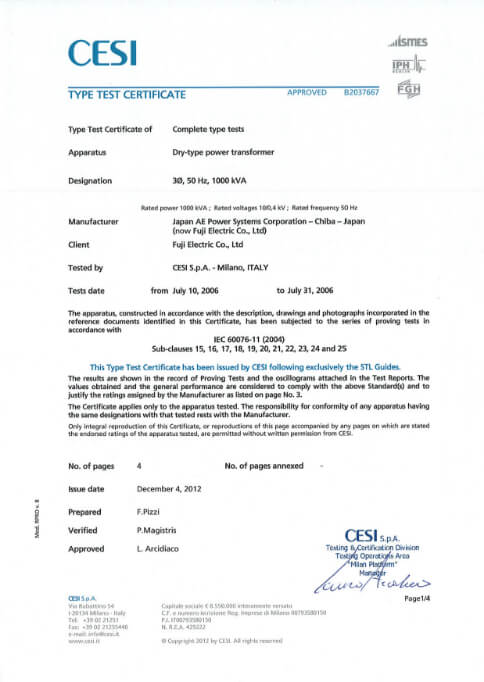

In fact, Fuji Electric is the only company in Japan to have obtained international certification.

Moriya: Fuji Electric is the only company in Japan that has passed the type test and obtained the certification of the IEC international standard for fire resistance. I think that is something we should all take more pride in.

Takano: There is a saying, “The next process is the customerʼs,” but that doesnʼt mean that we make the product and weʼre done, and after that itʼs up to the customer. I understand it to mean that we have to be strict at our own stage of the work so as not to cause trouble later in the next process. There definitely was a steadfast conviction toward reliability.

Keep asking what truly makes a good product and keep chasing that performance. And always have a steadfast conviction toward reliability. This is the essence of Fuji Electricʼs manufacturing. That spirit has come to fruition in the form of our 100,000th MOLTRA.

To keep supporting the changing energy market.

As well as the 100,000-unit milestone for MOLTRAs, what else is needed for Fuji Electricʼs manufacturing to support society long into the future?

Enta: The energy market is very brisk, and Fuji Electricʼs technologies are keeping pace with the changes in energy, so it is important that we respond to those changes.

In addition to MOLTRA, what else is needed for Fuji Electricʼs manufacturing to support society long into the future? Moriya wound up the discussion with these words.

Moriya: Without distinctive features in both our products and our attitude, we would not survive, and I donʼt think we would reach 150,000 MOLTRAs. The strengths of this company are the way in which everyone engages in manufacturing from our customersʼ perspectives and our teamwork when we are trying to send new products out into the world. Because we have that spirit, I believe we can build a framework to cooperate with each other in the pursuit of our dreams. I hope we will continue to be a manufacturer in which both the salespeople and the people in development value our customers. That is my strong wish.

Watch it to hear the three experts talking in their own words.

Recommended

October 31,2024

October 21,2024

October 2,2024

August 21,2024