Fuji "MOLTRA" Cast-Resin Dry Type Transformers

Fuji Cast Resin Transformers

Our company

-

Fuji Electric developed our first cast-resin transformers in Japan in 1974.

-

Third party certification of IEC60076-11 was obtained in 2006

-

We have sold over 100,000 units in 55 countries.

We offer reliable and industry-proven transformers to meet the needs of our customers.

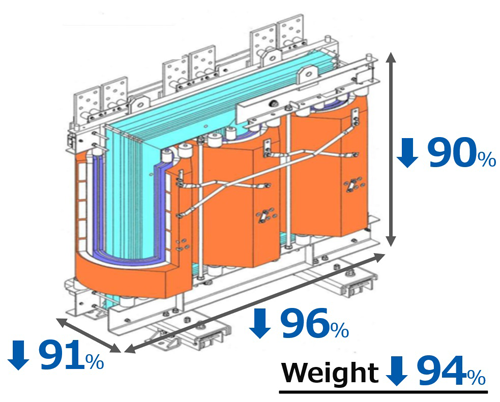

Downsizing

Downsizing comparison with 22kV 2000kVA conventional model.

Standard Specifications

Standard design

-

Rated voltage; up to 36kV, Rated power; up to 4,000kVA

-

Insulation system temperature; 155℃(F)

-

Type of cooling; AN (Naturally-Cooled), AF (Forced-air-Cooled)

-

Maximum ambient temperature; 40℃, yearly average temperature; 20℃

-

Utilizing aluminum for winding and copper for terminal

-

Climatic, environmental and fire behavior classes C2, E2 and F1.

Optional design

-

Insulation system temperature; 180℃(H)

-

High & Super-high efficiency type

-

Low noise type

-

Maximum ambient temperature 50℃

-

Rectifier transformer (provision for harmonics)

-

In-rush current reduced design to standard value 15~20 times

-

Winding temperature rise reduced design for higher ambient temperature site

Applications

From everyday buildings and factories to socialinfrastructures for energy and transportation.

Active wherever electricity is used.

Applicable locations

-

Railways

-

Multistory buildings

-

Semiconductor factories

-

Buildings Hospitals

-

Hotels Laboratories

-

Shopping centers Schools

-

Art galleries Theaters

-

Stadiums Petrochemical plants

-

Industrial complexes Underground railways

-

Railway substations Cranes

-

Tunnels Power supplies for construction sites

-

Water and sewerage plants Wind farms

-

Refuse disposal plants Data centers

-

Semiconductor factories

Product Features

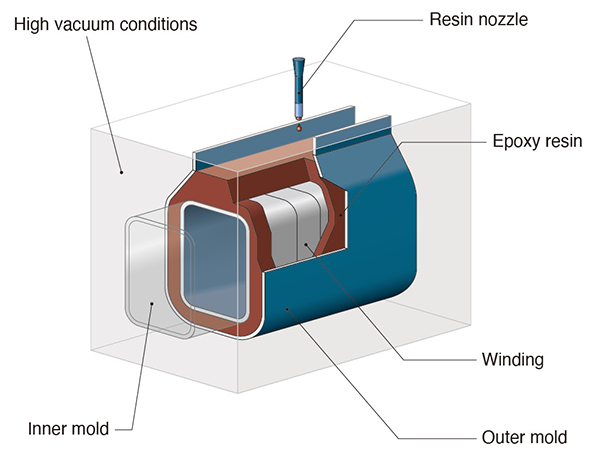

Vacuum-Casting

Our product is manufactured with vacuum casting method using a premium metal pattern, resulting in a thick resin layer with a smooth surface

IEC Certification

Fuji Electric’s cast resin transformer have passed all tests of IEC 60076-11:2018 including special test and type test.

-

Climatic class: C2 (crack resistance)

-

Environment class: E2 (moisture resistance)

-

Fire behaviour class: F1 (fire resistance)

-

Short-circuit test

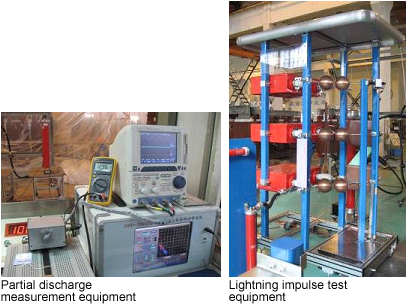

Partial Discharge Free

Void-less : Excellent partial discharge characteristics.

In order to maintain superior quality, Fuji Electric voluntarily adopted the following stricter standard:

All units are subjected to partial discharge test.

Voltage that is twice that of the operating system is applied to ensure safety

Partial discharge is less than 10 pC (Pico-coulombs intensity)

Cast resin transformers are also coated in high-vacuum chambers to reduce air and other gases in the resin that could produce partial earth discharges. In effect, they hermetically seal the transformer's core.

Shop Test Items

Measurement of insulation resistance

Measurement of winding resistance

Measurement of voltage ratio and phase displacement check

Measurement of short-circuit impedance and load loss

Measurement of no-load loss and current

Separate-source AC withstand voltage test

Induced AC withstand voltage test

Partial discharge measurement

Lightning impulse test

Temperature-rise test

Measurement of sound level

Applied standards

-

IEC60076-11

-

ANSI/IEEE C57.12.01

-

GB6450, GB/T10228

-

JEC-2200 etc.

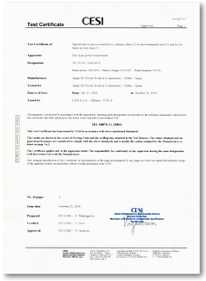

Third Party Certification of IEC60076-11

Fuji cast resin transformers were officially certified after successful completion of all test items under IEC60076-11

This includes special test items and type test items by KEMA and CESI.

Certificate organization KEMA(Netherlands), CESI(Italy)

Features

Japan's first manufacturer to obtain IEC60076-11 certification

Third party certification ensures objective confirmation of product compliance

Special test certification; climatic class C2 (crack resistance)

; environmental class E2 (moisture resistance)

; fire behavior class F1 (fire resistance)

; short-circuit test

Production Bases

Fuji Electric Corporation has two cast resin transformer production bases:

Chiba Factory in Japan, and Fuji Manufacturing Thailand