Pure Water Vaporization-cooling Silicon Rectifier

Features

-

Pure water vaporization natural cooling

This epoch-making natural vaporization-cooling rectifier uses pure water for the coolant. There is no impact at all on the Earth's environment. -

Japan's largest silicon rectifier diode

We developed this high-voltage, large-capacity silicon rectifier diode based on our many years of experience and technology in power semiconductors. We have achieved a product with a significantly reduced number of parts, that is compact and lightweight, and features high efficiency. Reduction rates: 40 % volume, 30 % floor space, 40 % mass, 40 % losses. (Reduction rates are in comparison with our 6,000 kW PFC vaporization-cooling rectifier.) -

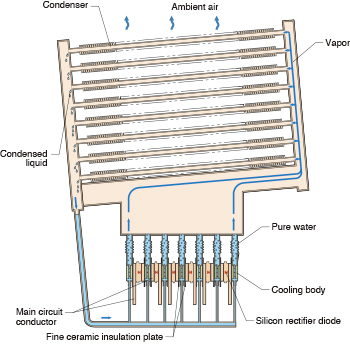

Fine ceramics insulation

The use of fine ceramics with high thermal conductivity and high insulation on both sides of the cooling body insulates the silicon rectifier diode and the main circuit conductor enabling the entire unit to have ground potential. -

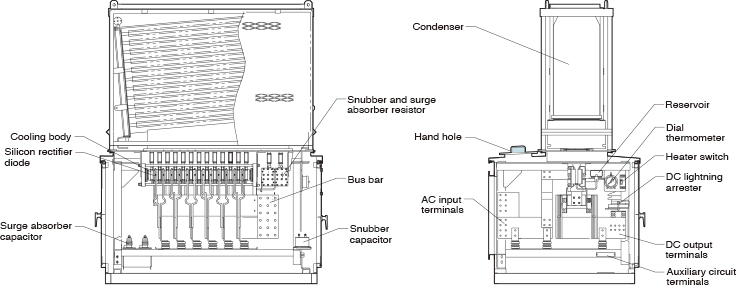

Completely sealed structure

We have achieved a completely sealed structure that uses vaporization cooling such as for the snubber and surge absorber resistors, and reduces the temperature rise in the stack storage unit.

Cooling principle

The heat generated by the silicon rectifier diode vaporizes the pure water inside the cooling body. At that time, the large latent heat of vaporization efficiently cools the silicon rectifier diode. The water vapor is cooled in the condenser and returns to the cooling body to become a liquid again. Note that the vessel is under constant negative pressure.

Silicon rectifier diode

Internal structure

Standard specifications

-

*1

-

Minimum ambient air temperatures of -5°C and -10°C are for variable conductance.

-

*2

-

Better than three-phase bridge series (series 12-pulse) in all respects: dimensions, mass and efficiency. Interphase reactor is not required.