Instrumentation

Ultrasonic Flowmeter for Steam <FSJ>

Clamp-on type saturated steam flow measurements

Transmitter(FSJ)

Detector(FSX)

Transmitter(FSJ)

Detector(FSX)

Contributes to “visualization” of steam flow and works in combination with EMS to optimize energy and achieve energy savings.

-

Installable without turning off steam line

No piping work required -

Effective use of steam energy without pressure loss

-

Less maintenance costs due to no moving parts

Catalog

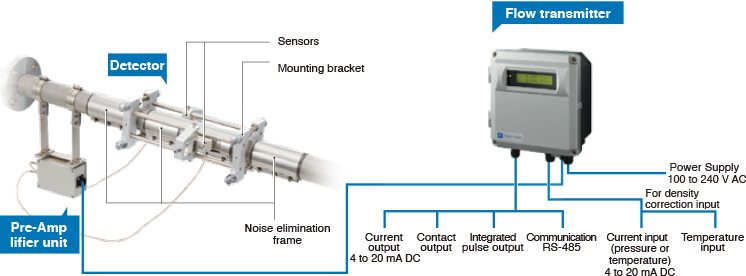

Equipment configuration

Features

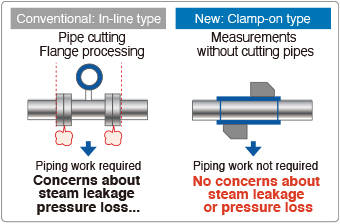

No plumbing required

Installable with no pipe cutting or flange processing. Installable without stopping production lines and no steam leakage concerns since plumbing is not required.

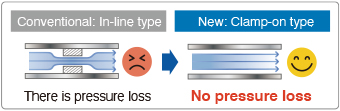

No pressure loss

The ultrasonic sensors do not interfere with the steam flow.

Less maintenance cost

No moving parts help to reduce regular maintenance costs such as cleaning.

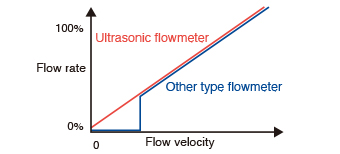

Enables measurements at low flow rates

The ultrasonic flowmeter can meusure at low flow rate, even at flow rates of 0.

Convertible to mass flow rate

The measured volume flow measurement and density (fixed value) input can be converted to mass flow rate and output. Density correction can also be performed by measuring the pressure (4 to 20 mA DC) and temperature (with resistance bulb) of the saturated steam and inputting as external signal (AI).

Accurate flow measurement

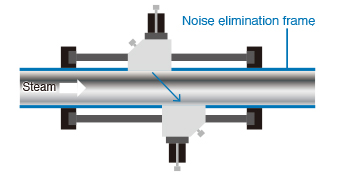

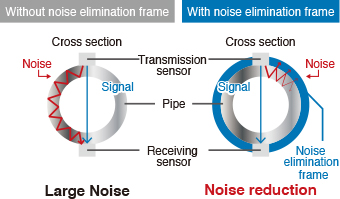

Noise elimination frame

The heat-resistant rubber frame on the piping surface can reduce noise and accurate cabtuning of the ultrasonic signals is achieuable.

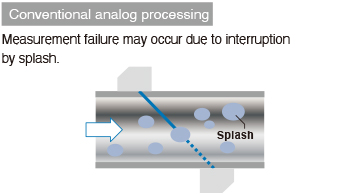

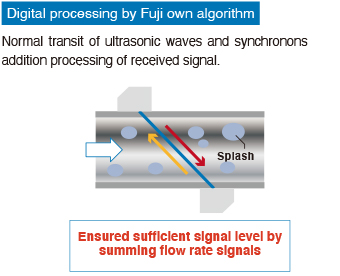

Algorithm dedicated for steam measurement

Specifications

Measurement may be unavailable depending on conditions.

Fuji Electric’s EMS Solution

“Visualization”, “Recognition” and “Optimization”.

The 3-steps contrubute to your energy management sollution, based on our vision of creating daily and continuous improvement of “energy management”.

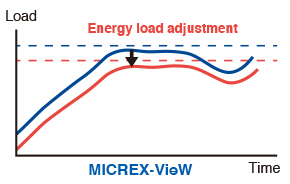

STEP1 Visualization

Understanding energy usage

Understanding present situations and taking effective action immediately

-

Ascertaining the state of energy by measuring it at key points

-

Deploying known and feasible energy-saving measures

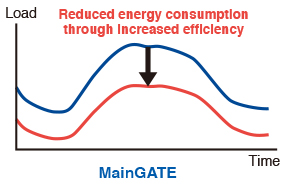

STEP2 Recognition

Energy management

Countermeasure point extraction and effect analysis

-

Achieving points of improvement while eliminating waste through energy-saving analysis support environment deployment

-

Establishing a daily improvement cycle

-

Model energy consumption trends through data collection

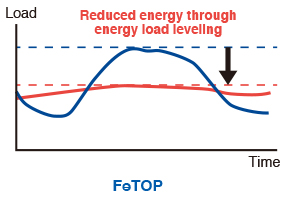

STEP3 Optimization

Energy usage optimization

Optimized usage, management and capital investment

-

Further reducing energy costs through use of energy-saving equipment and control technology

-

Achieving optimum supply control based on energy consumption models

-

Leveling energy loads through use of power generation and storage devices

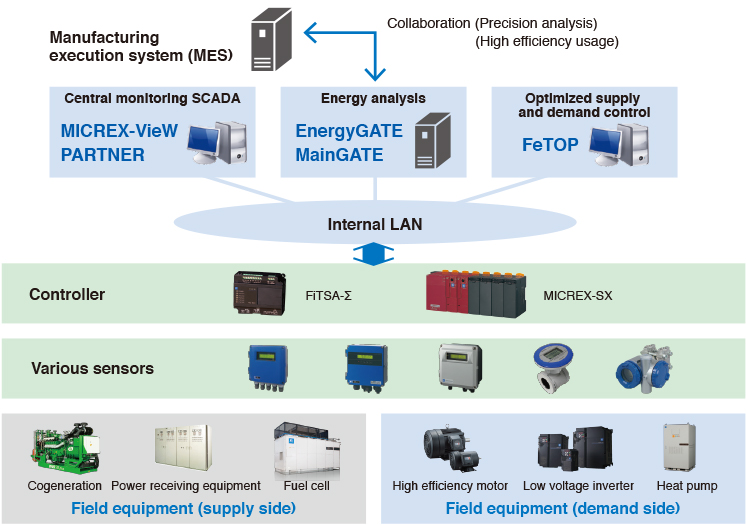

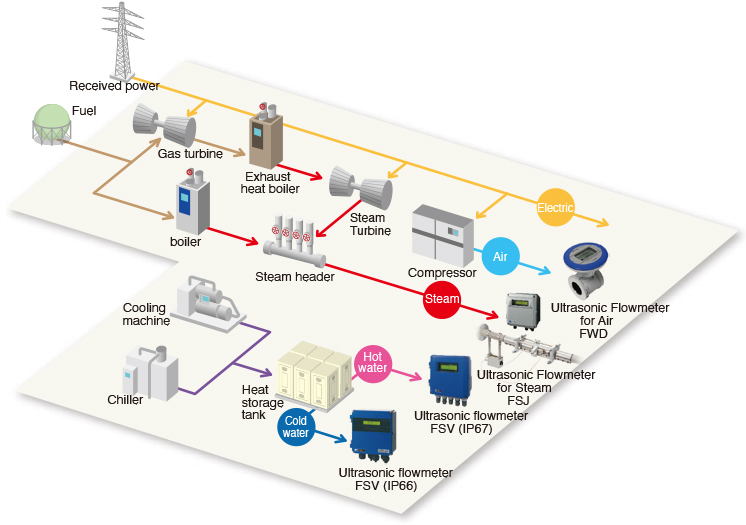

Energy plant Configuration example

Measurement of energy (e.g., electric, water, air, steam) used in factories classified by system. Ascertainment of state of actually used energy and achievement of energy savings through optimized usage.

Ultrasonic Flowmeters

Easy installation, space savings.

Easily deployable ultrasonic flowmeter S-Flow

Clamp-on type saturated steam flow measurements

Highly accurate and non-contact measurement<br> Ideal for multi-point measurement in the field

Highly accurate and non-contact measurement<br> For pipes ⌀13–⌀6000 mm

Highly accurate and non-contact measurement<br> Offers consumed energy calculation, 2 pipe measurement, 2-path measurement for 1 pipe

Non-contact measurement Compact transmitter

For pipe diameter from 25 mm to 1200 mm

Non-contact measurement For pipes ⌀25–⌀200 mm