Instrumentation

Double Beam NDIR Gas Analyzer <ZKJ>

Simultaneous and continuous measurement of up to 5 components among:

NO, SO2, CO2, CO, CH4, N2O, and O2

Ideal for flue gas monitoring in incinerators and industrial furnaces

NO, SO2, CO2, CO, CH4, N2O, and O2

Ideal for flue gas monitoring in incinerators and industrial furnaces

-

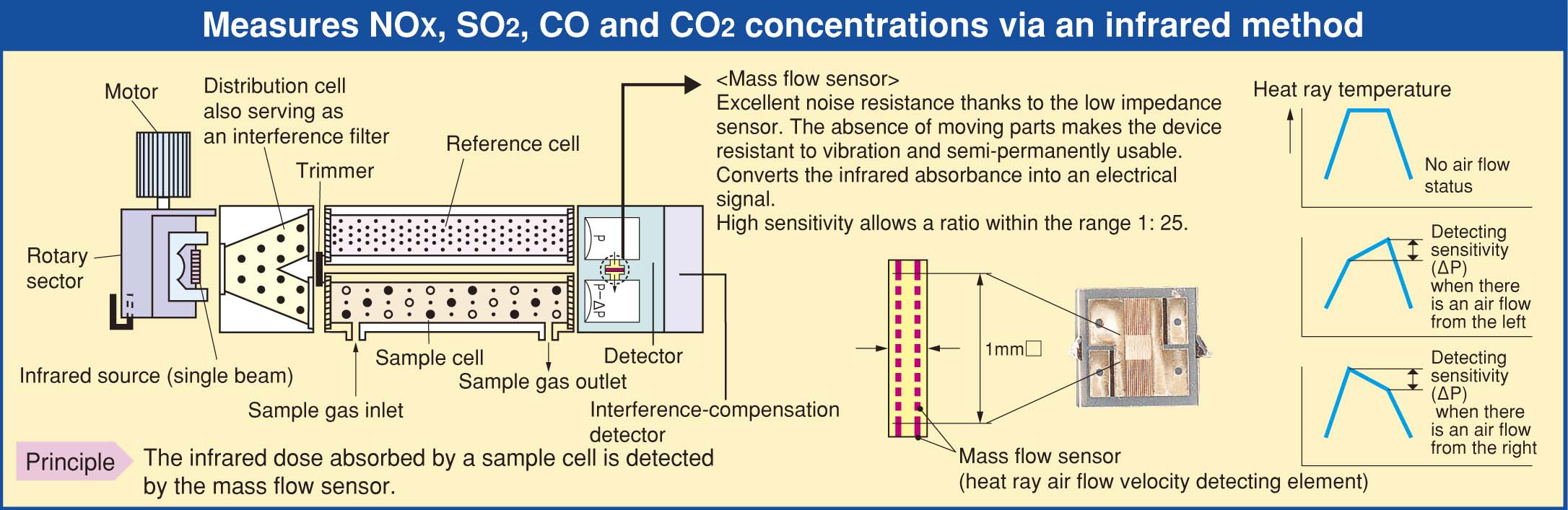

The mass flow type twin detector — hardly affected by interference gas

-

A variety of functions: auto calibration, O2-corrected output, averaging, alarm, etc.

-

Easy-to-see LCD

You can check the concentration changes of all components at a glance -

19-inch rack mount

-

Maximum range ratio 1 : 25

A user can set or change a range within the limit -

Zero drift for 200 ppm range: ≤ ±1% FS per week

Manual

Specifications

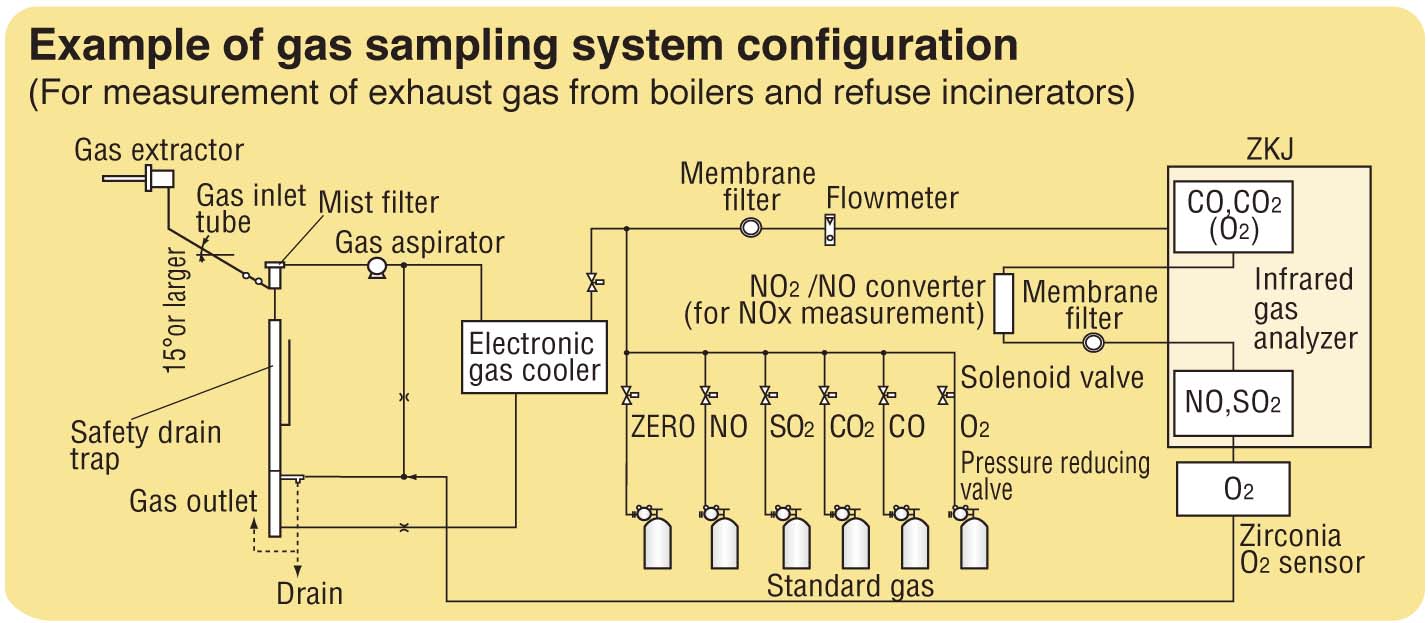

Gas sampling system configuration example

The following diagram shows a typical sampling system for monitoring five components in flue gas from boilers or incinerators.

We can configure an ideal system for any application.

Gas Analyzers

• Double-beam NDIR sensor + O2 sensor

• Long-term stability

• Continuous measurement of up to 5 components

• Single-beam NDIR sensor with sample switching system + O2 sensor

• Excellent zero-point stability

• Continuous measurement of up to 5 components

• Monitors up to 7 gas concentrations

• Space-saving design

• Direct insertion type

• Continuous measurement of HCl, NH3, O2, CO, CO2, and CH4 in flue gas

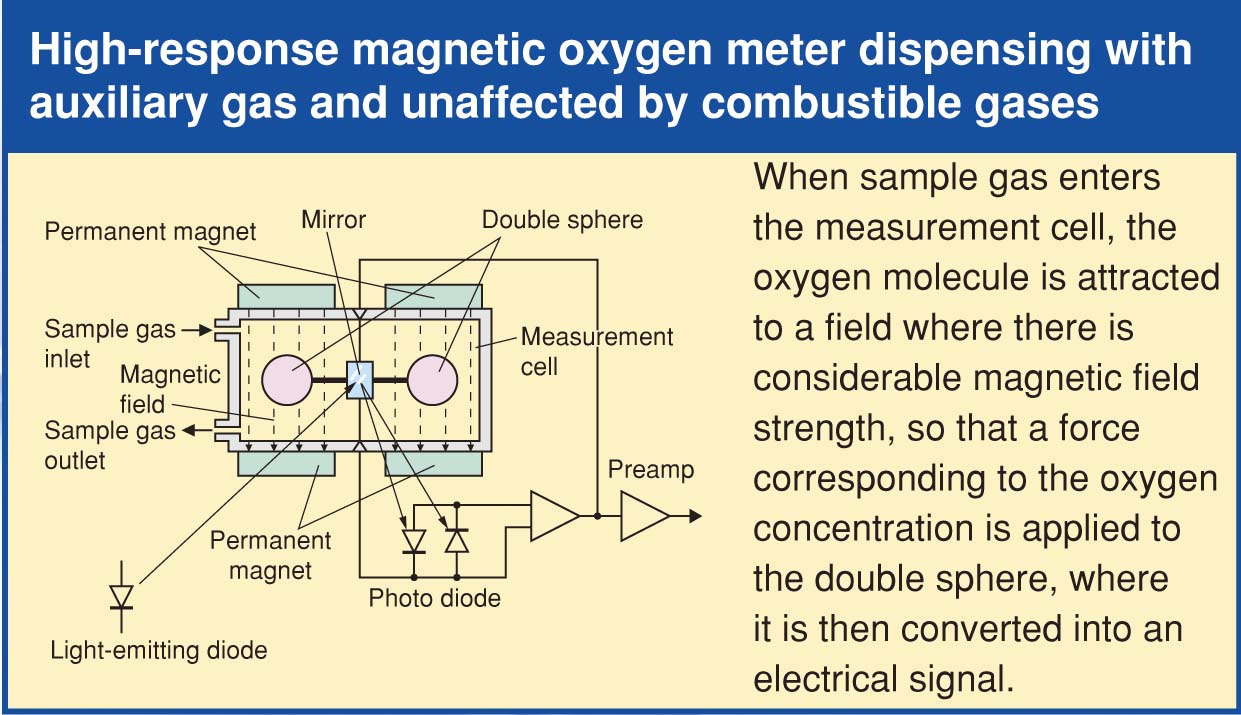

• Continuous measurement of O2 in combustible gas

• Ideal for combustion control

• Double-beam NDIR sensor

• Continuous measurement of up to 5 components

• Single-beam NDIR sensor

• Compact and light weight

• Continuous measurement of up to 5 components

• Single-beam NDIR sensor with sample-switching system

• Continuous measurement of up to 5 components

• Single-beam NDIR sensor with sample-switching system

• Continuously measures low concentration (0•5 ppm) gases

• Single-beam NDIR sensor

• Compact and light weight

• Continuous measurement of up to 5 components

Best suited for H2, He, and Ar measurement

Ideal for H2, Ar, and He measurement

• Fast response

• Communication function

• Ideal for measuring oxygen in combustible gas

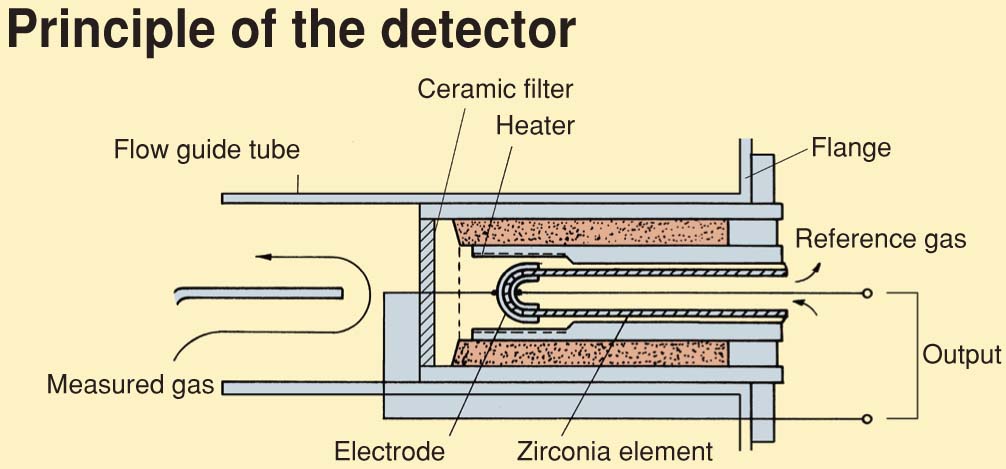

• Insertion type

• No need for gas sampling device

• Measures O2 in incombustible gas

In-situ oxygen analysis requires no gas sampling device

Ideal for combustion control in industrial boilers and furnaces

• Insertion type

• No need for gas sampling device

• Measures O2 in incombustible gas

• Simultaneously measures up to 5 components among NOx, SO2, CO, CO2, CH4, and O2

• No need for gas sampling device

Simultaneously measures up to 4 components among CO, CO2, CH4, and O2

Continuous measurement of CO, CO2, CH4 in heat treatment furnace

• Measures CO2 in the air

• Analog output and alarm output

Measures H2S, CH4, CO2, and O2 generated in biogas plants

• Double-beam NDIR sensor

• Compatible to obsoleted ZRG

• Single-beam NDIR sensor

• Compatible to obsolated ZRH

• Single-beam NDIR sensor

• Compatible to obsolated ZRJ

Gas extractor, pump, cooler, filter, converter, etc.