Brake Motors

There is an accelerating trend among major countries to adopt high-efficiency standards (legal regulations and policies) for motors (3-phase induction motors) in order to conserve the global environment and prevent global warming.

Japan has also mandated a "Top Runner System," which came into effect on April 1, 2015 after the amendment and notification* of the "Act on the Rational Use of Energy (Energy Conservation Act)."

● IEC60034-30 ● JIS C 4034-30

(Efficiency classes of single-speed, three-phase, squirrel-cage induction motors)

-

High-efficiency

Top-runner standard value compliant!

-

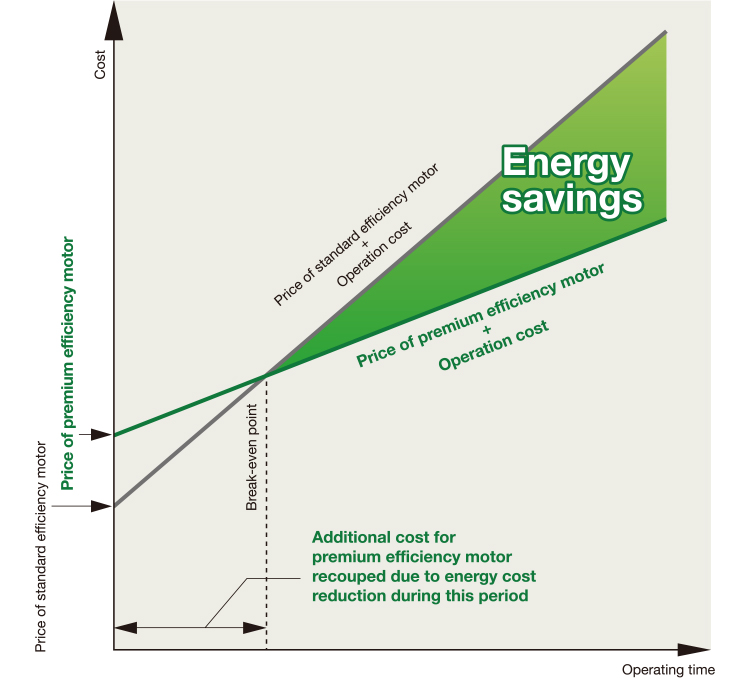

Energy saving

Running cost greatly decreased!

-

Easy replacement*1

Same frame size and connecting dimensions as standard motors!

-

Capable of operation in combination with an inverter

-

Compliance with the environmental burden material (including 6 substances) of the European RoHS Directive *2

-

Non-asbestos material specifications

-

With loosened brake handle

-

Easy brake maintenance

-

Adoption of plastic thin-type terminal box

-

Note

-

*1is based on comparison with our previous products

-

-

*2includes lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyl (PBB) and polybrominated diphenyl ethers (PBDE)

-

Note

-

Listed with the product number code omitted Part number code: MKS1XXX

Standard inventory products

Standard inventory products

Built-to-order products

Built-to-order products

Production not possible

Production not possible

-△ starting

-△ starting