Motors / Applied Products

Synchronous Drive System

Next generation synchronous drive systems for more energy savings and space savings.

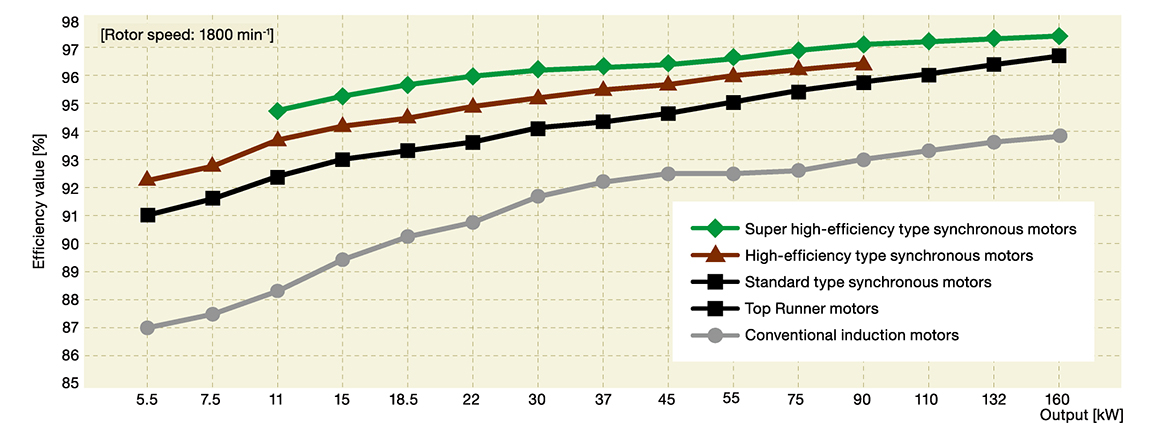

A synchronous motor is a motor that incorporates a permanent magnet in the rotor. A synchronous motor differs from induction motors and top runner motors in that there is no flow of secondary current, because the magnetic flux is generated from the permanent magnet, thus resulting in a higher level of efficiency with significant loss reduction in a smaller size with a lighter weight. We have a three-model series including a standard type, high-efficiency type and super high-efficiency type. Achieve greater energy and space savings by deploying our next-generation synchronous drive systems that combine various FRENIC-MEGA (G2) Series inverters and synchronous motors.

-

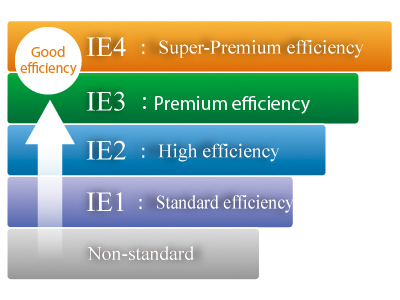

IEC60034-30

(Efficiency classes of single-speed, three-phase, squirrel-cage induction motors)

-

Uses copper bars with Ni and Sn plating

-

Ambient operating temperature up to +55°C

-

*

-

Derating is required when used at 50°C or higher.

-

Further strengthens PCB coating

(JIS C 60721-3-3/IEC 60721-3-3 Class 3C2)

-

*

-

Salt-resistant products, etc., can be manufactured to order.

-

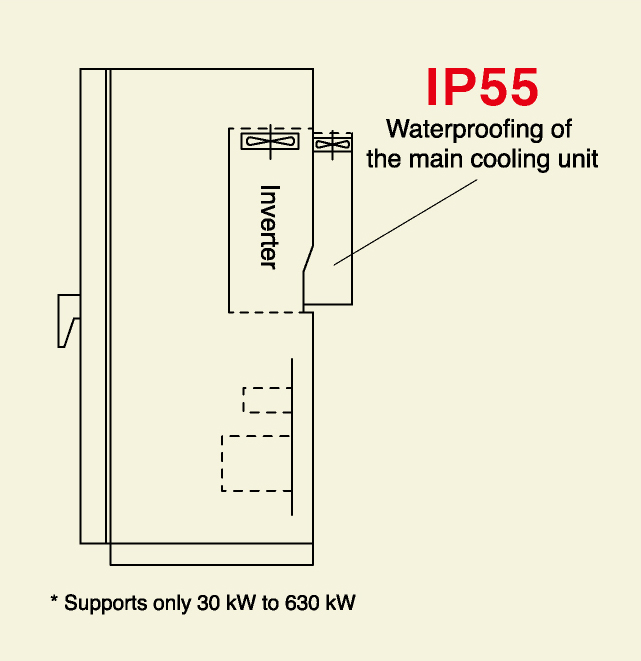

IP55 protection for the inverter’s main cooling unit contributes to enhanced cooling outside the panel, lower costs, and downsizing

-

Note

-

If you are using or considering using the product under the following conditions, please contact our sales department.

-

a.

-

Environments containing sulfurized gas (e.g., some applications in the tire manufacturing, paper manufacturing, sewage treatment, textile industries, etc.)

-

b.

-

Environments containing conductive dust and foreign objects (e.g., metal processing machines, extruders, printing machines, waste disposal machinery, etc.)

-

c.

-

When using the product in non-standard environments

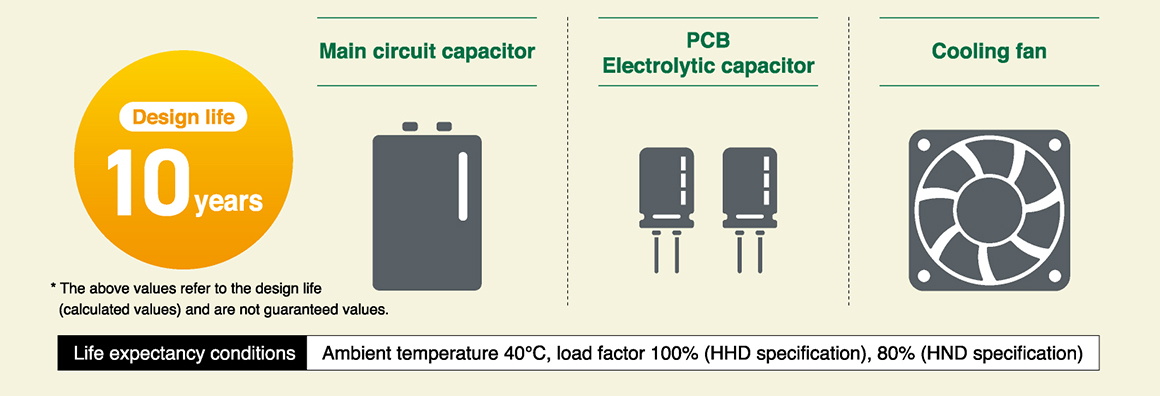

Many of the serviceable parts inside the inverter have been designed to meet customer equipment maintenance cycles.

Compliant with overseas safety standards.