Synchronous Motors

Standard type sensorless GNB2 Series

-

High efficiency and energy savings

Motor efficiency same level as IE3 (premium efficiency)!

Note: IE3 is an efficiency class based on IEC 60034-30. -

Compact and lightweight

Volume ratio: On average 35% improvement,

Mass ratio: On average 40% improvement ! (in-company comparison)

The motor frame number of frames 1 to 3 is lower than that of induction motors. Machinery can be made compact and space-saving. -

High power factor

Reduces the power receiving equipment capacity !

In addition to high efficiency, the higher power factor than the induction motor can lower current capacity of the equipment. -

Maintenance friendly

Easy bearing replacement !

A structure that facilitates bearing replacement work without taking out the rotor improves on-site replacement and work efficiency.

-

Note 1

-

Special-purpose motors with base rotor speeds of 1000, 1200, 1500, 3000, and 3600 min-1 can also be manufactured.

-

Note 2

-

Contact us when switching from commercial operation.

-

Note 3

-

Flange mounting type can be manufactured for motor frame numbers of 160 and below.

-

Note 4

-

Contact us if you require a special-purpose motor with a rated output of 3.7 kW or less, or a motor over 315 kW.

Slide base rails

Dimensions for the standard type GNB and GNF2 series only

〔Unit: mm〕

-

Note 1

-

Only available for the GNB2 Series (sensorless) and GNF2 Series (with sensor) standard type synchronous motors.

-

Note 2

-

The above are all standard inventory products.

-

Note 3

-

The paint color is Munsell N1.2 (black).

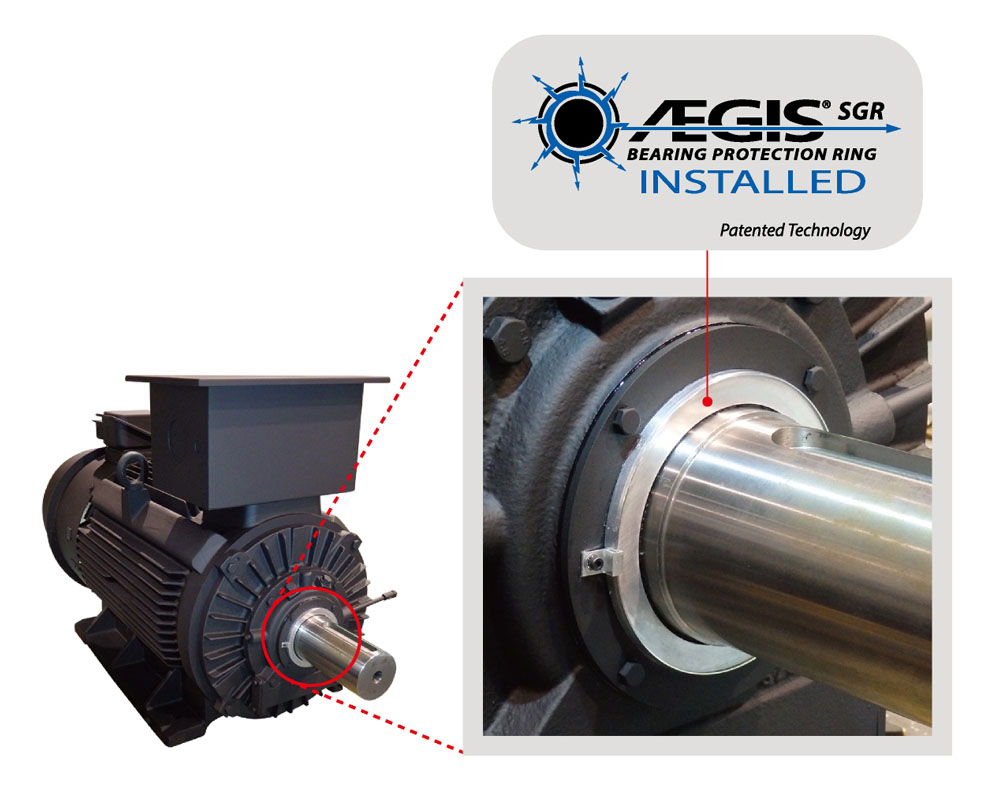

Grounding rings

In general, a grounding brush is incorporated in motors with frame numbers of 225 or higher to prevent bearing electric corrosion. The grounding brush is a consumable part and must be replaced periodically. A maintenance-free grounding ring (Aegis® SGR) is also available as an option when it is difficult to replace the grounding brush depending on the installation location or operating conditions.