Contribute to Decarbonization at convenience store with the Developed New ”Store Controller”

With a market shore of over 40% in refrigerator and freezer showcases, Fuji Electric supplies around 56,000 convenience stores throughout Japan. We have now developed the “New Integrated Store Controller,” which allows operators to control energy use throughout their store and is nearly ready for launch.We offer this controller as a total solution that will give you an edge in tackling the challenges faced by the convenience store industry, such as energy conservation and decarbonization.Fuji Electric interviewed three employees who were involved in the development of this product.

Showcases alone aren’t enough!Reduce CO2 emissions throughout your store

In 2012, Fuji Electric developed the “Integrated Store Controller,” which allows operators to manage the temperature and operating statuses of food refrigerator and freezer showcases. The product is designed to be installed in a store’s backyard and is offered in packages that include showcases. To date, we have sold around 6,000 units to convenience stores located all over Japan.

Since the government's October 2020 declaration of the goal to achieve carbon neutrality by 2050, the industry has been busy taking action.

The Food and Beverage Distribution Division's Hirotaka Urabe, who is in charge of sales for convenience stores, shares his thoughts.

“The power used by refrigerator and freezer showcases accounts for about 40% of the electricity used in a convenience store. Energy conservation in showcases is essential for achieving significant reductions in CO2 emissions, but we now know that this alone isn’t enough.”

In April 2023, Fuji Electric began to take tangible steps toward the development of the “New Integrated Store Controller,” which would be capable of conserving energy throughout stores, thereby contributing to the decarbonization of convenience stores. Specifically, the “New Store Integral Controller” is a system that interconnects showcases, air conditioners, ventilators, lighting, and other equipment to control the amount of energy used.

There is a limit to the amount of energy that can be saved from showcases alone. The rest will be taken care of by the New “Store Controller.” To achieve the energy conservation targets of convenience stores, “we needed ideas that customers can never imagine,” notes Urabe.

Aim to surpass your energy saving targets

Connecting showcases to other equipment required increasing data communication and raising the CPU’s processing speed to more than triple the previous rate.

Taichi Mouri, who is tasked with the electrical design of wires and circuit boards at the Development Department, says, “Manufacturing a product of this processing speed was a first for Mie Factory. It was very difficult to design.”

Development was expected to take considerable time, but Mouri came up with the idea of using a simulation development tool used at Tokyo Factory, his previous workplace. This led to the reduction of labor hours and development time.

Meanwhile, Makoto Kishikawa, who developed the software to synchronize showcases with the New Store Integral Controller, was exploring energy control conditions.

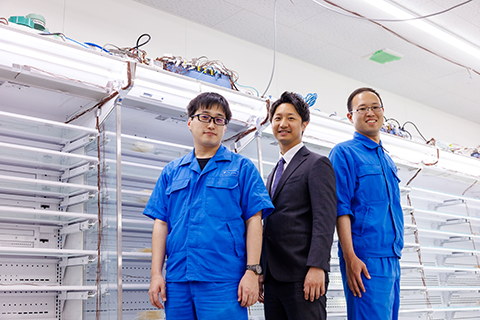

What he did was take a year’s worth of data from showcases at numerous convenience stores to replicate a setup in a laboratory store within Mie factory, from which he collected data on energy consumption while taking into account equipment operation.

To conserve energy to the maximum extent possible without sacrificing food refrigeration safety, they made many adjustments through trial and error under various conditions to see how the cooling rate changes according to changes in the temperature outside of the showcase. They adjusted the data exchange specifications for integration with other equipment, such as air conditioners, and reviewed the benchmarks for achieving energy savings.

“We adjusted the software specifications so that customers can not only reach their targets but also achieve greater precision in control,” Kishikawa explains.

Address the worker shortage faced by convenience stores

To support the ever-evolving convenience store industry, the New Integrated Store Controller can be given multifunctional capabilities with online software updates. However, hardware installed at stores cannot be replaced easily.

“Bearing in mind the functions that could potentially be added in five or ten years, hardware specs need to have extra capacity reserved in preparation for future updates. We put a lot of effort into reaching a compromise between cost aspects and specs,” Mouri recalls.

Kishikawa aimed to achieve not only energy conservation but also the reduction of labor costs at convenience stores as an additional benefit of online integration.

“In response to changes in outside temperature, the system automatically adjusts the internal temperature of the showcase to a suitable level, thereby maintaining food safety while at the same time cutting down on wasteful energy consumption.Moreover, we centralized all kinds of data from the showcase in the cloud server so that any abnormality the showcase may encounter can be predicted. With alarms generated before problems actually occur, preventive maintenance contributes to minimizing the impact on store operation,” Kishikawa explains.

They also designed the system to be easy for users to operate. Urabe of the Sales Section conducted hearings with convenience stores and maintenance companies and communicated their feedback to the development staff. The controller has been optimally designed for user-friendliness in terms of screen size and operability.

“Creating something from nothing is the best part of design development. It feels rewarding to be able to say with confidence that I designed the convenience store facilities that people encounter in their day-to-day,” Mouri says.

Further decarbonization with “All Fuji Electric”

In response to environmental concerns and rising electricity prices, a proactive investment trend toward photovoltaics and other renewable energies is starting to take shape among convenience stores.

Fuji Electric also develops storage battery systems that can effectively utilize renewable energy. Fuji Electric is also considering utilizing the New Integrated Store Controller in renewable energy management systems by integrating the product with power conditioners. Maximizing energy efficiency in response to changes in power consumption at the store can result in both decarbonization and lower electricity costs.

“Sharing technologies across all of Fuji Electric helps us expand our ideas,” Mouri relates. “It's because it helps us brainstorm how one technology can be repurposed for other products.”

Trust in the sales department generates the motivation to develop

Kishikawa, who is in his fourth year at the company, says that he is not the type of person who communicates very proactively. But for the development of the New Integrated Store Controller, he took the initiative in visiting other departments and collected a considerable amount of data to develop a product that can control the energy of diverse types of facilities.

“It was my first experience communicating closely with people from other departments after joining the company. I feel a sense of accomplishment in the way I created opportunities for myself to earn the cooperation of people working on other products and sales representatives.”

Urabe, who is in his tenth year at the company, says that the reason for his choice to work at Fuji Electric was the people.

“I enjoy working in sales because in my work environment, everyone around me helps me without asserting hierarchical relationships. That’s exactly why young employees like the three of us are able to play key roles and work with drive,” he explains.

(From left: Kishikawa, Urabe and Mouri)

Mouri explains the relationship between the three. “I admit that when the sales department asks us to accept technologically difficult development tasks, I sometimes feel frustrated. But we trust Urabe. We know that if we produce a good product, he will explain its merits to the customer effectively. This motivates the development staff to do their best in the face of difficulty,” he relates.

The three employees were tasked with the development of the “New Integrated Store Controller,” which was designed to provide support for ever-evolving convenience stores and will be launched in 2025.

Recommended

July 30,2025

July 28,2025

July 7,2025

July 2,2025