Next-Generation Energy—Expanding the Use of Hydrogen and Ammonia: Achieving Technological Breakthroughs in Various Fields with Sensing Technology

Hydrogen and ammonia are attracting attention as new sources of energy to replace fossil fuels in order to realize carbon neutrality. However, hydrogen is combustible, and ammonia is toxic. Therefore, they must be handled carefully.

Technology that can quickly and accurately measure (sense) concentrations and flow rates is essential for the safe utilization of these two sources of next-generation energy. Fuji Electric is currently developing measuring equipment for hydrogen and ammonia using the sensing technology it has cultivated over many years. We talked to four members of the development team.

Increasing Sensitivity, a Technical Challenge for Analyzers

Hydrogen and ammonia, which do not emit CO2 when burned, are expected to be utilized in power plants, ships and factories as next-generation energy sources that will contribute to decarbonization. Sensing technology is one of the keys to addressing challenges in expanding the utilization of these energy sources.

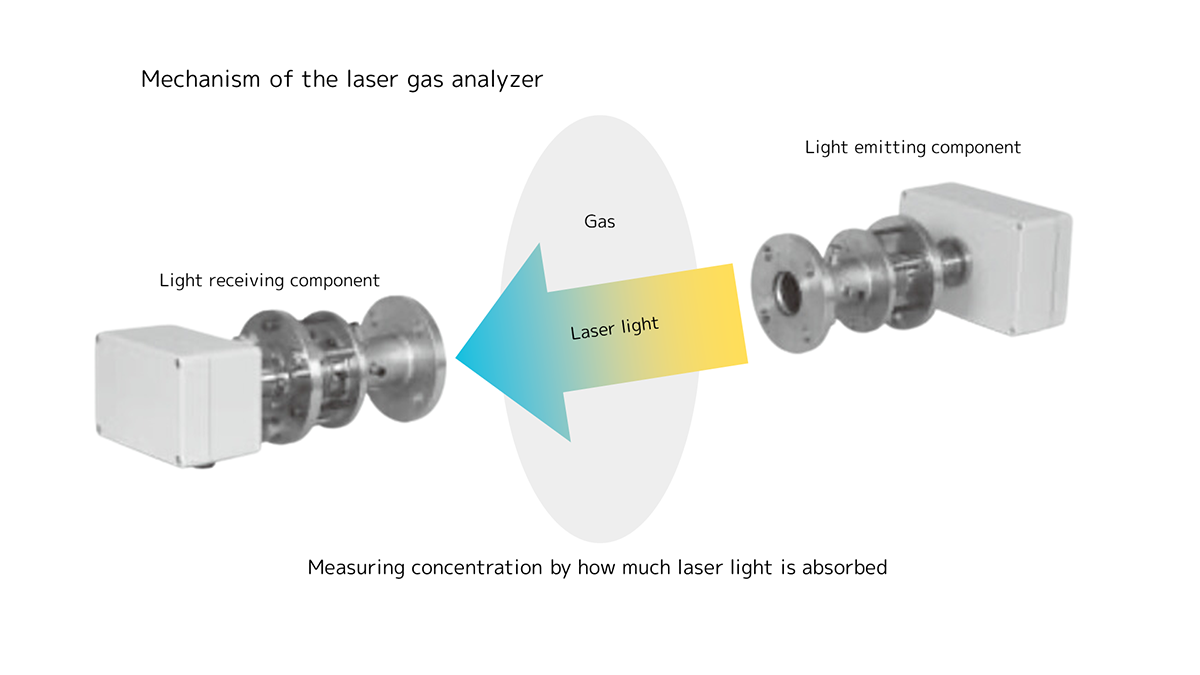

When laser light is shone on a gas, the gas absorbs light of a specific wavelength. Developed by Fuji Electric, the first laser gas analyzer sold in Japan leverages this phenomenon. By measuring gas concentration based on changes in light between the emitting and receiving components, it is possible to inspect for leaks or other issues in the surrounding area.

However, the light absorption rate of hydrogen or ammonia is low, making it difficult to measure the gas concentration.

“The key to development was to determine how we can increase the sensitivity of the analyzer,” says Shrestha, who has been with our company for six years and has been engaged in efforts to launch this product.

Reducing Waveform Noise

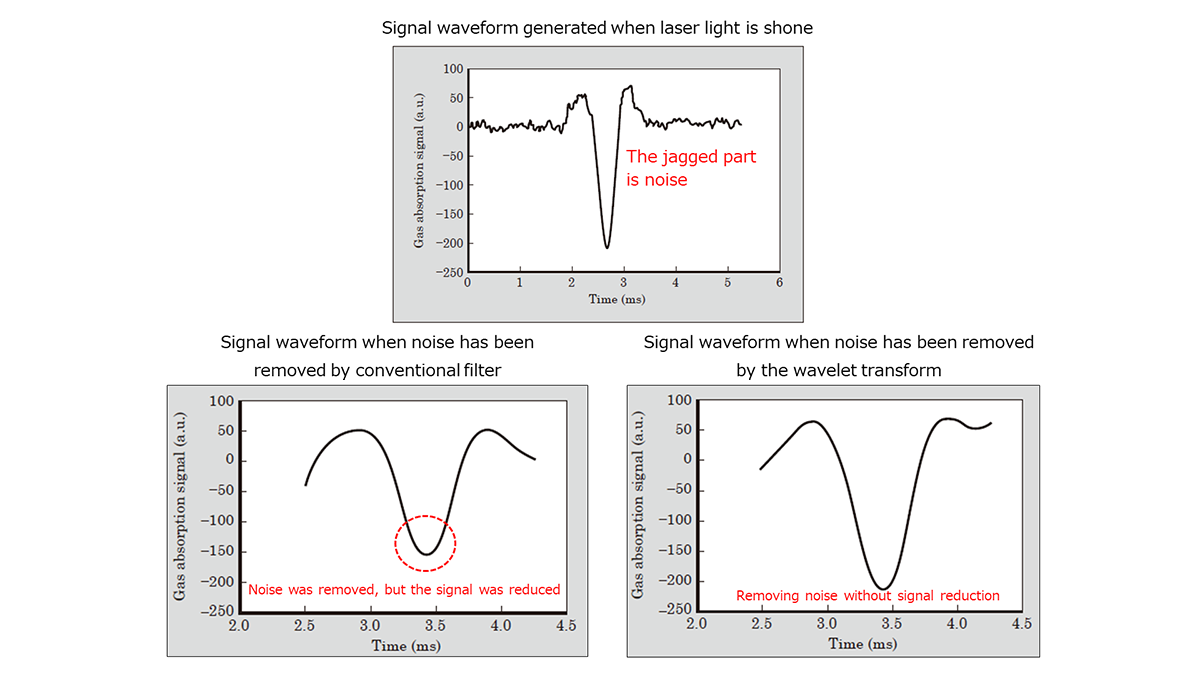

What can be done to increase the sensitivity of the analyzer? When laser light is directed at a gas, and the signal is displayed as a waveform, noise can be observed. When measuring the concentration of hydrogen, ammonia, or any other gas, it is necessary to eliminate this noise as much as possible. However, conventional noise removal filters also reduce the signal.

As mentioned above, the signal of hydrogen and ammonia is very small, as it naturally has a low light absorption rate. As such, the gas concentration cannot be accurately measured by using conventional filters. This is what made development challenging. “The key was figuring out how to reduce noise without reducing the signal,” says Yoshimine, who has been involved in the development of sensing technology since joining our company in 2016.

The research had seen progress and setbacks since it began in 2021. But then, there was a breakthrough.

Solving Problems Using Image Processing Technology

The team leader upheld a policy of keeping an eye out for technologies in various fields, even in unrelated disciplines. With this policy in mind, the team conducted research using information from various academic societies and literature sources.

In September 2022, a year and a half after development began, the team leader called in Yoshimine, along with Teraoka, who had been with the company for six months at the time, suggesting that they try a certain signal processing method.The method involved wavelet transforms, a signal-processing technique used in image processing and other fields.

Realizing that this method might just work, Teraoka immediately began running a simulation on his PC. The noise in the waveform was completely eliminated.

In October, the technique was incorporated into an analyzer. We began conducting experiments, and our development efforts seemed to be proceeding smoothly. But then, we encountered a new obstacle.

“The central processing unit (CPU) used in the gas analyzer took too long to compute. Increasing the processing power of the CPU increases the cost. We conducted repeated studies on how to transform the waveform efficiently,” explains Teraoka.

In February 2023, Yoshimine and Teraoka came to the conclusion that only the pinpoint data required to measure gas concentrations should be transformed. “I felt a sense of achievement because I was able to produce results from an idea that had never existed before,” says Yoshimine.

Utilizing Sensing Technology Developed in Geothermal Projects

The development of the gas analyzer was now on a clear path forward. However, in order to actually use next-generation energy, flow rates must be measured in addition to gas concentrations.

Ammonia has been used in products like fertilizers, and flow meters for measuring liquid ammonia have been commercially available. However, flow meters for liquid hydrogen did not exist. This is because the liquefaction temperatures of ammonia and hydrogen are different. In order to develop a flow meter for hydrogen, problems specific to hydrogen needed to be addressed. One such issue was the fact that mixed-phase flows(Note) tended to occur.

-

(Note)

-

"Mixed-phase flow" refers to the mixing of substances in different states, such as liquid and gas, or liquid and solid.

Hydrogen liquefies at an extremely low temperature of −253°C. In liquid form, the volume is 1/800 of that of the gas. Therefore, hydrogen is often delivered in liquid state. However, it is difficult to maintain this extremely low temperature, and some of the liquid tends to evaporate during transportation. The ratio between liquid and gas needed to be measured in order to accurately determine the flow rate of liquid hydrogen at the delivery destination.

Jimbo, who joined our company in 2018, had previously studied the principle behind sensors that measure the flow rate of geothermal steam, a mixture of gas and liquid, while conducting research and development on geothermal power generation. In April 2023, the development team for the hydrogen flow meter was formed. When Jimbo was appointed as a member, he felt that he must conduct research and development on these sensors, despite the fact that they were used for a different purpose.

The development of a sensor with no commercially available precedent was a process of trial and error, but a prototype was completed in the spring of 2024. For safety reasons and other factors, handling liquid hydrogen is very difficult, and few facilities are available for conducting experiments in Japan. For these reasons, the first tests were conducted using liquid nitrogen.

“The accuracy is still low, but we can confirm that it works as a sensor. Going forward, we will increase the accuracy and perform tests using actual liquid hydrogen, with the goal of launching the product as soon as possible.”

Working Toward Product Launch in FY 2026

Prior to the flow meter, the team had made progress on the analyzer by introducing wavelet transforms, and they continued research to further enhance its sensitivity.

In March 2024, Fuji Electric proposed the development of peripheral equipment for the formation of an ammonia-fueled ship supply chain in a project to develop next-generation ships, which was sponsored by the New Energy and Industrial Technology Development Organization (NEDO) as Green Innovation (GI) Fund Project, and the proposal was accepted. The team is now working on a technology for measuring whether ammonia remains in the pipes of ammonia stands used to fuel ships at sea.

Yoshimine (left) says, “The most important foundation for working sustainably is health and safety. With these in place, you can concentrate on your research.”Jimbo (right) says, “I have been blessed with opportunities to study new things through research in different fields. I have realized the importance of consistently incorporating new technologies into my work and in my personal life.”

“Now that the usage environment has become clear, we can anticipate specific problems as we proceed with development. We aim to have the analyzer on the market by the end of FY 2026,” Shrestha explains.

Breakthroughs in measuring equipment for both hydrogen and ammonia were triggered by technologies used in different fields. The flexible thinking of young researchers will contribute to decarbonization, a challenge shared across the globe.

Recommended

December 4,2025

July 30,2025

July 28,2025

July 7,2025