S-FORMER-mini

Fuji Electric's highly reliable thyristor DC power supply unit is the fruit of our substantial expertise in large-current technology nurtured over the years. Select the most suitable design for your facility, based on the wealth of available options.

Features

High reliability

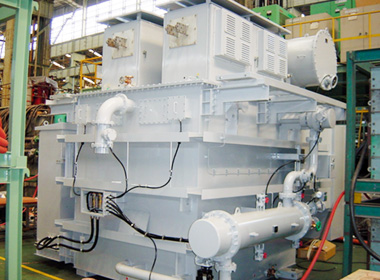

Configuration featuring a rectifier mounted on a transformer

260V DC, 26kA

Our large-current rectifier (trade name: S-Former) technology, typically used for aluminum electrolysis, has been employed in small to medium capacity devices to achieve high-reliability design.

Efficiency measurement by combination tests

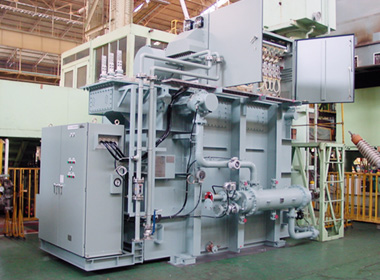

Configuration featuring a rectifier mounted on a transformer

510V DC, 16.5kA

Achieving high efficiency is critical for large-current rectifiers. We conduct combination tests of transformers and rectifiers to measure and verify efficiency before delivery.

Simplified on-site installation achieved by the delivery of an integrated unit

For overseas installations, the rectifier and transformer can be integrated as one single unit, optimizing the reduction of required installation space at your facility.

150V DC, 52.5kA

150V DC, 52.5kA

Extensive menu selections available for various applications

Control

Applicable to ACR, AVR, AWR, and other special control operations.

-

Standard control accuracy: ±2% (Higher accuracy optionally available.)

Direct digital control devices (DDC) are also available (option)

(connectable with optical fibers)

Cooling

-

Transformer:

Oil/water-cooled, oil/air-cooled, oil-immersed self-cooled, oil-immersed air-cooled, dry self-cooled, dry air-cooled, dry water-cooled, and molded type cooling systems are available. -

Rectifier:

Water-cooled, water/air-cooled, direct water-cooled, air-cooled, circulated air/water-cooled, water-cooled/water/air-cooled purified water cooling systems are available.

Structure

A rectifier is mounted on a transformer, which minimizes the installation space required.

-

Standard design for indoor use includes panel structure with ventilation.

-

Optional design for indoor use includes totally enclosed structure to provide protection from atmosphere.

-

Standard design for outdoor use includes totally enclosed panel structure.

Harmonic disturbance suppression

The harmonic disturbance incoming to a rectifier can occasionally cause problems. Multi-phase (12, 24, and 48 phases) rectification and harmonic disturbance suppression by harmonic filters for the entire systems can be applied, based on our abundant experience and substantial analysis.

Applications and specifications

-

*1

-

: Per double-star-connected 12-phase rectifier

options

Numerous options are available to satisfy your specific needs. The following outlines only some examples of the many available options:

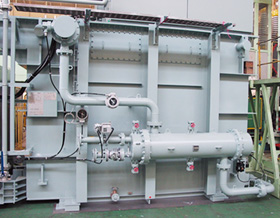

Spare cooling system

A spare cooling system can be mounted, in addition to a purified water cooling system for the rectifier and a cooling system for the transformer.

(with a spare)

(with a spare)

Ladder and inspection deck

(with a ladder and inspection deck)

80V DC, 60kA

To facilitate and for ease of maintenance, a ladder and an inspection deck, like that typically mounted on a transformer, can be mounted to the rectifier.

Rectifier inspection window

(with inspection windows)

162.5V DC, 12kA

Windows for inspecting the inside of a rectifier can also be provided.

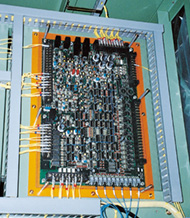

Optical link between the control unit and the rectifier main unit

A control unit installed a distance away and an on-site rectifier can be connected via fiber optic cable, which facilitates changes in control constants from the distant location. The maximum distance between the control unit and rectifier is 100 meters, when utilizing the fiber optic cable.

Direct digital control unit (DDC)

In addition to standard analog type control units, direct digital control units are also available. The control constants of DDCs can be easily changed using an exclusive loader. In the unlikely event of a rectifier failure, each waveform can be stored and transmitted for failure analysis and prompt response.

A redundant thyristor for parallel connection

A redundant thyristor element is available for parallel connection, which allows continued operation in the rare event of thyristor element failure an unexpected.

System coordination

Fuji Electric Systems has the capability to supply a total power conversion system, taking each customer's specific power system in to consideration to result in optimum performance. This includes both harmonic and power factor studies, as well as supply of all related equipment.

Remote control

Remote control systems for use with a control panel, PC, and POD are also available.