Servo Systems

ALPHA7S | Overview

Overview

The Basic Performance at the Highest Level in the Industry

High-speed and high-precision control is realized by the basic performance at the highest level in the industry

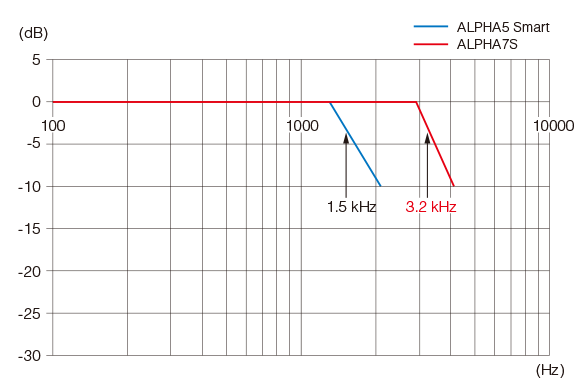

Speed and frequency response at 3.2kHz

Realizes Ultra-High-Speed Control

Fuji's proprietary control algorithm achieves a speed and frequency response at 3.2kHz, the highest level in the industry. This reduces the tact time, enabling high-speed control.

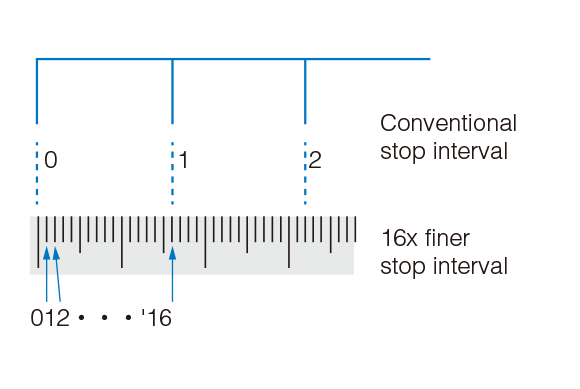

The 24-bit fine resolution INC/ABS encoder

Signifi Cantly Improves the Precision of Control

The encoder resolution is now as high as 24bits. This provides much higher control precision than before, enabling high-precision control.

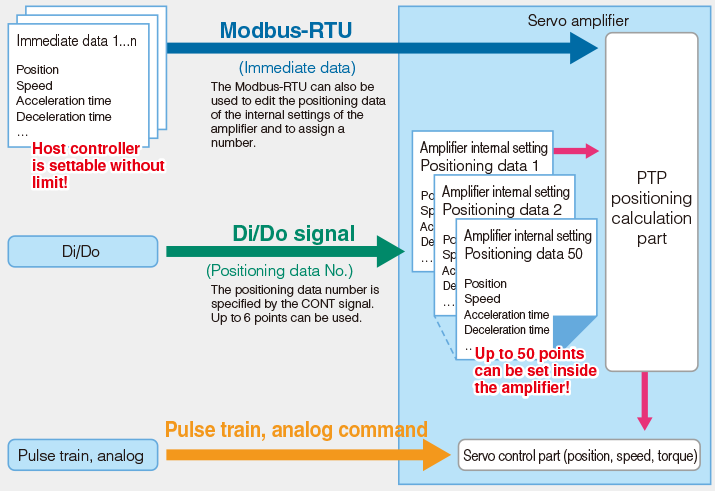

General-Purpose Interface ALPHA7S VVS Type

A single unit allows

-

Positioning run (immediate data operation) based on Modbus-RTU

-

Positioning run (with 50positioning data points) based on Di/Do signals

-

Position, speed, and torque control run based on pulse train/analog input

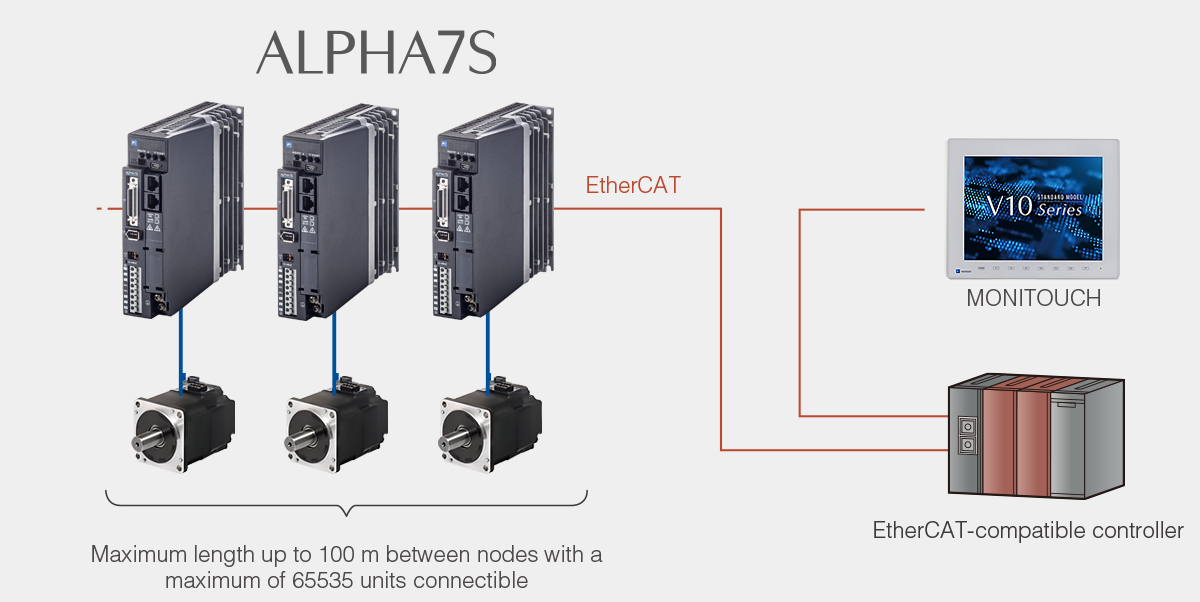

Open Network (with Support for EtherCAT) ALPHA7S VCS Type

Build and Tune Your System

System construction and tuning is easy and fast, and performance is maximized in combination with MICREX-SX.

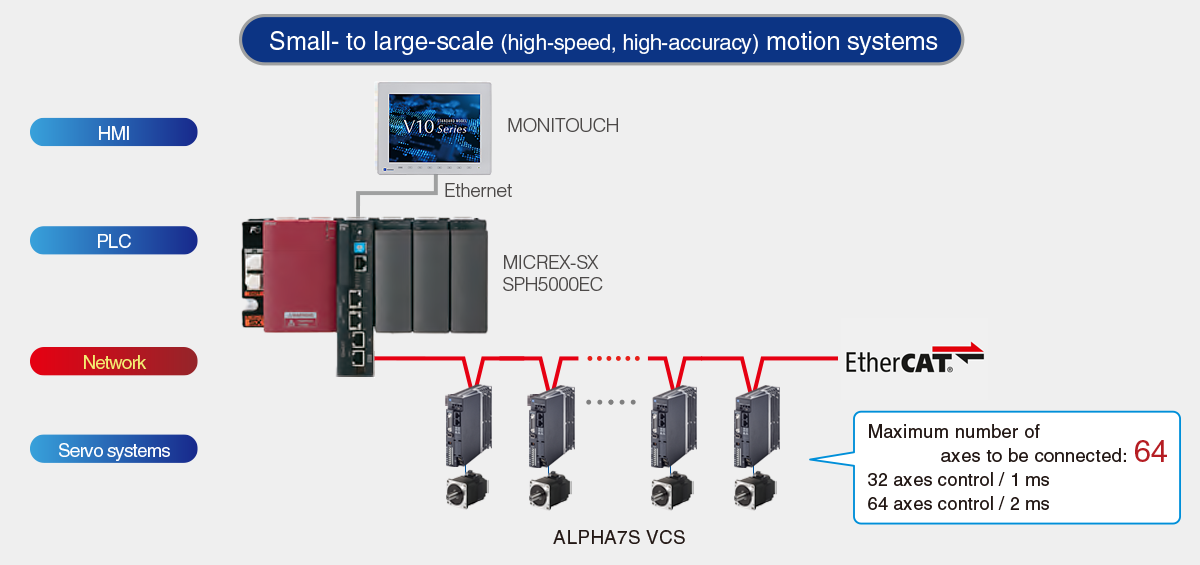

Combination with MICREX-SX

Scalable Motion Systems

When combining the servo with the EtherCAT-compatible SPH5000EC, users can build small- to large-scale (high-speed, high-accuracy) motion systems.

By combining a single SPH5000EC, a motion control system with ALPHA7S VCSs can connect up to 64axes to perform high-speed motion control for PTP positioning and synchronous control: 32axes at a control cycle of 1ms and 64axes at 2ms.

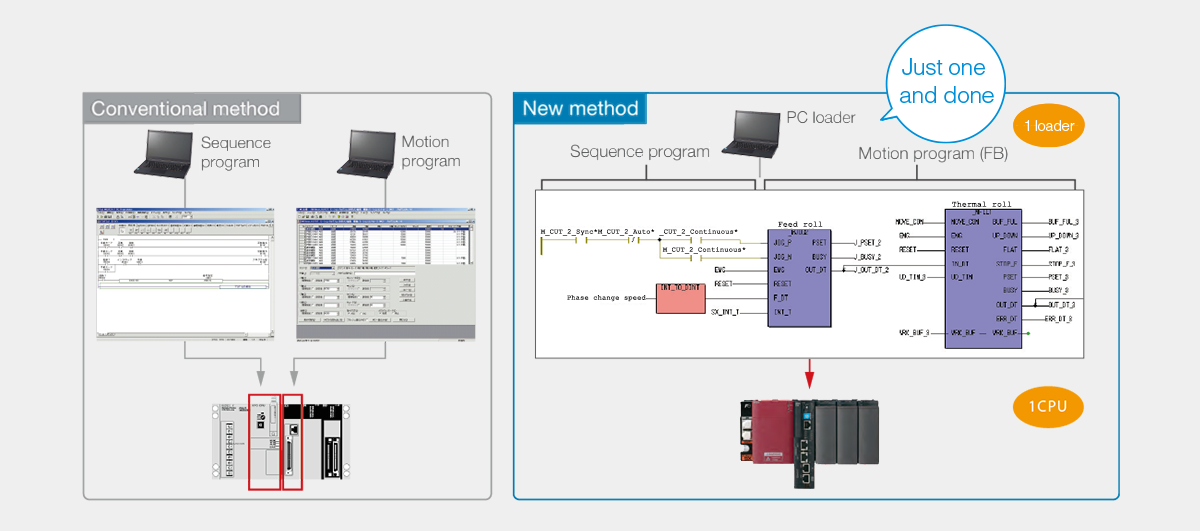

A Single CPU Performs both Sequence and Motion Control

Adding a single unit of MICREX-SX eliminates the need of a module dedicated to motion control, thus significantly reducing the initial cost. Also, work efficiency is dramatically improved by supporting both sequence and motion with a single programming tool(Note).

-

Note

-

SX-Programmer Expert (D300win)

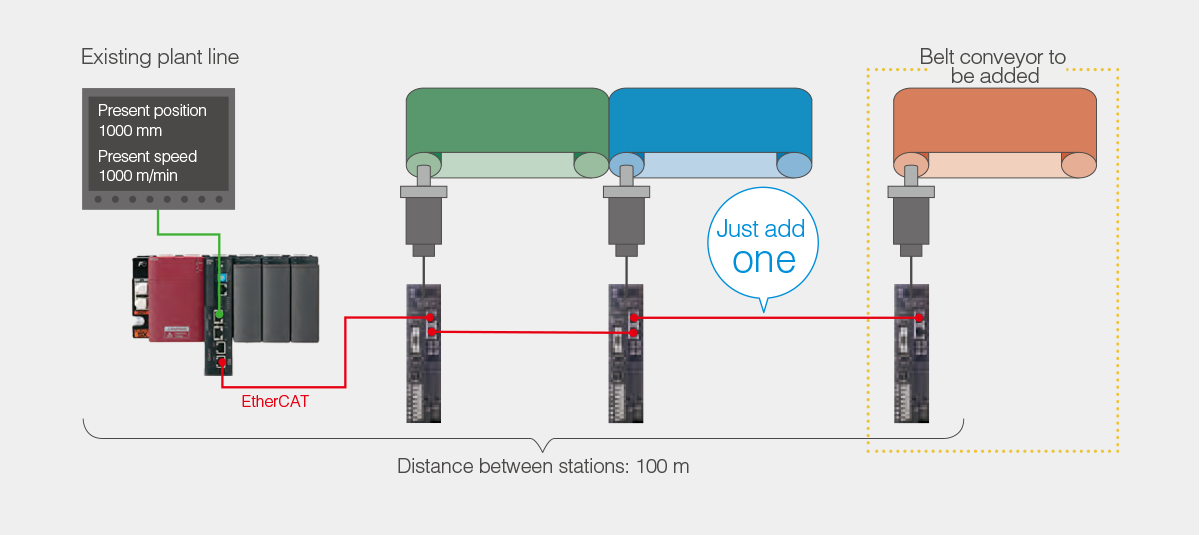

Directly Connectible with a Single EtherCAT and Easy to Wire and Extend

Just a single Ethernet cable completes the connection between the controller and servo. When you add an additional control axis to allow for the extension of the machine, you can connect it in a one-touch fashion using an Ethernet cable.

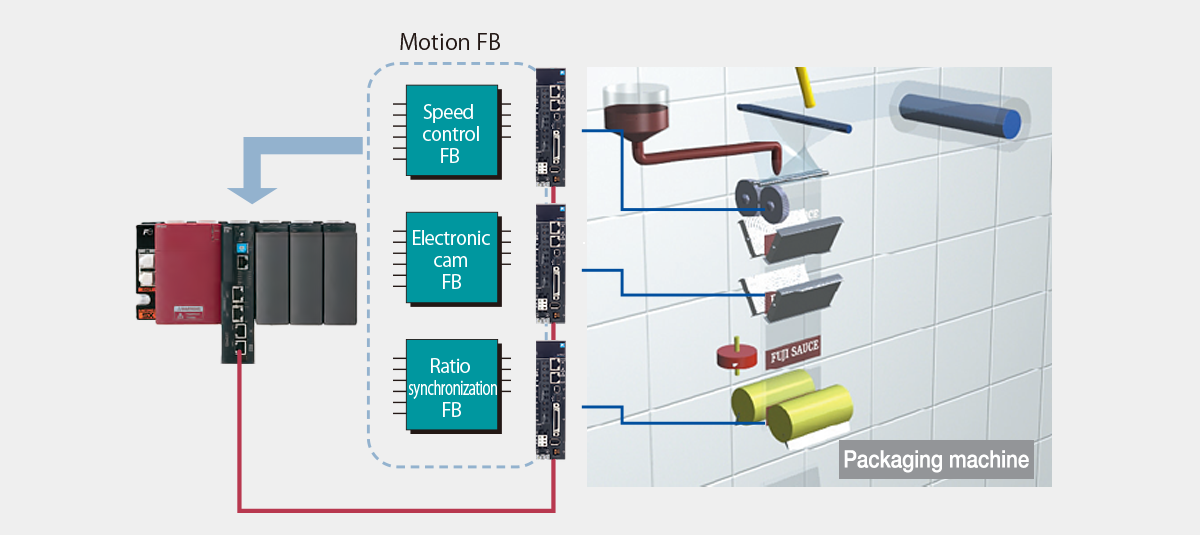

Broad Range of Functional Software “FBs” Raises Development Efficiency

Various software parts, FBs (function blocks), are available free of charge. By appropriately combining FBs, you can build a motion program for a large-scale system in a short time. If you have trouble in developing programs, consult Fuji for support.

Various Features that Allow Standalone Use of ALPHA7S

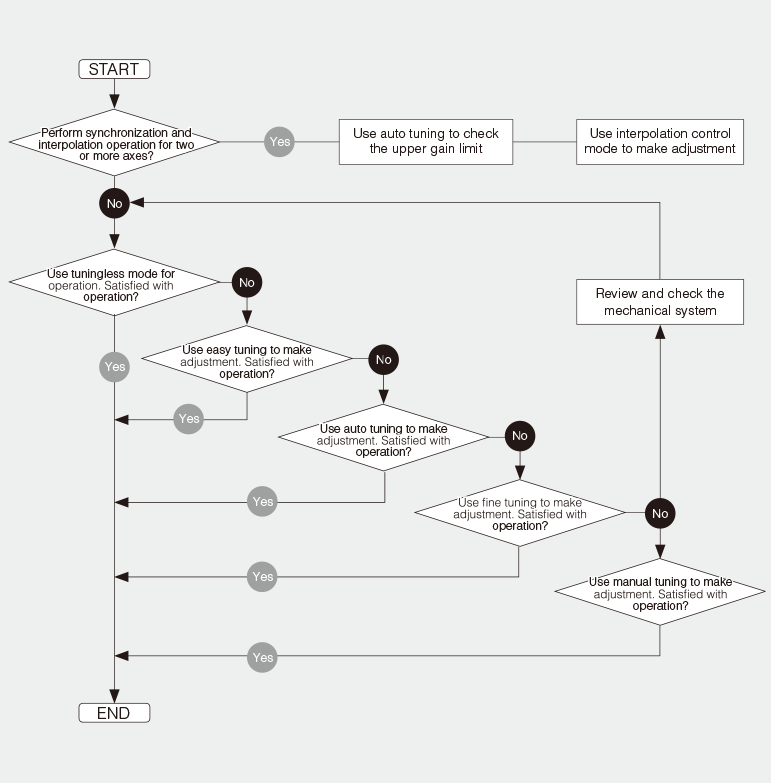

PC Loader Tuning Allows Easy Semi-Automatic Adjustment

In tuningless mode, you do not have to manually adjust the responsiveness (gain) because the servo system automatically does so. You no longer spend time on tuning at start-up time.

In auto tuning mode, the servo amplifier automatically adjust the responsiveness (gain). This mode allows finer control than tuningless mode.

This mode is intended for use with machines that require high precision. It allows you to optimize multiple parameters at once, enabling high responsiveness (gain) adjustment.

Features that Reduce the Time Required to Set Up a Newly Introduced Machine

You can adjust the machine and servo before completion of a program for the controller.

You can run a controller program before completion of the machine, so you can debug programs more efficiently.

-

Note

-

applicable to the ALPHA7S VVS type only

You can easily perform positioning run, using pre-registered positioning data. You can register positioning data for up to 50 points in the ALPHA7S VVS type. You can run the system by just selecting a program number and issuing a start command from the host controller. This feature is most useful for the purposes of inching and repetitive operations.

Operation and Stabilization of Quality

Evolved control functions contribute to streamlining ofoperation and stabilization of quality

Evolved Control Functions

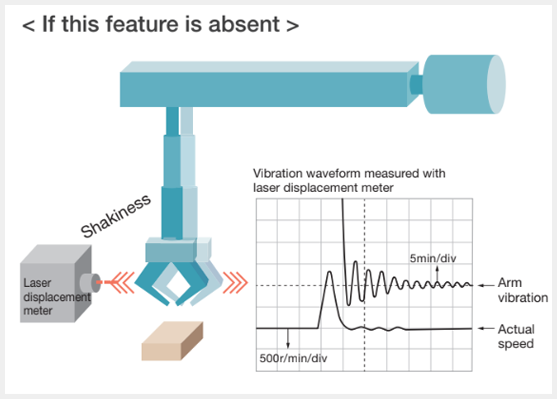

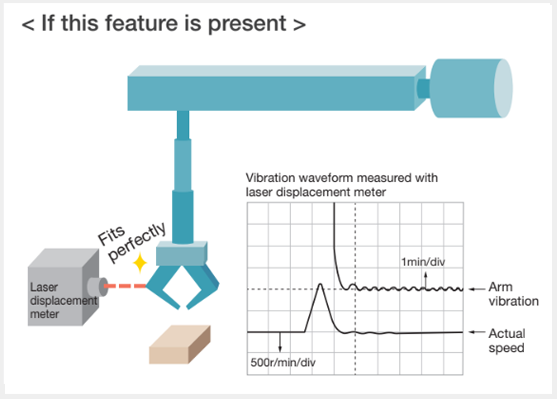

New Damping Control Suppresses the Vibration at Equipment Edges

The introduction of a new control algorithm reduces the vibration at the edges of the equipment to one tenth, compared with the conventional damping control (used in our products). Support for models with three inertia systems makes it possible to control low-frequency vibrations at two points concurrently.

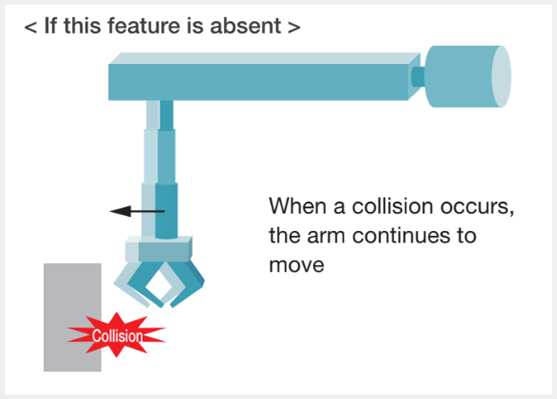

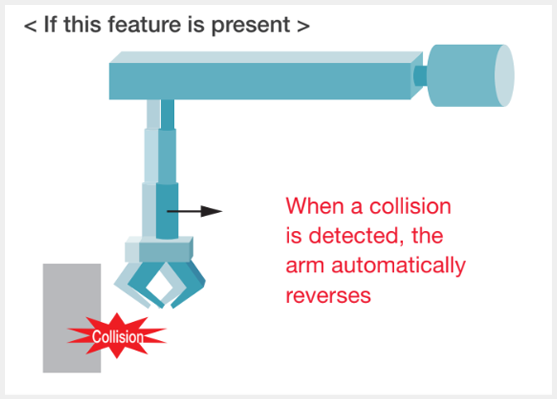

The Interference Detection Feature Detects a Collision, Etc. and Prevents Breakage

The servo amplifier detects interference on the equipment (such as a collision with an edge of the machine) and operates to mitigate the shock to the machine when a collision occurs. This feature helps prevent damage to the equipment and reduce load on it.

-

Note

-

Protection may not be complete depending on the operation type.

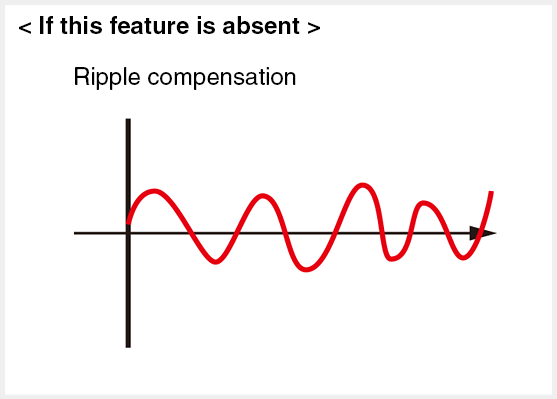

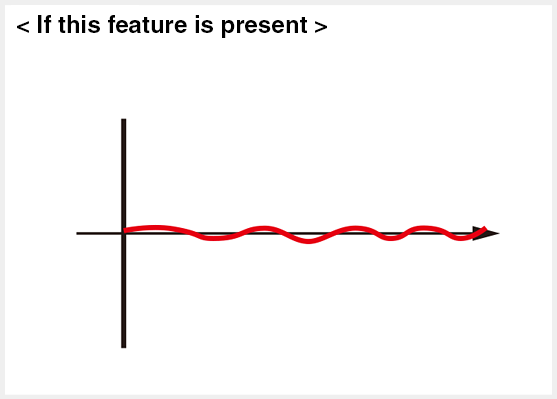

The Cogging Feature Ensures Smooth Operation

Since interference due to cogging of the servomotor is detected and compensated, speed ripples due to cogging can be reduced and smooth operation can be ensured even if the equipment does not support the increase of the speed loop gain.

Maximum Input Pulse Frequency of 4MHz

The system can support input frequencies from the host controller until the maximum frequency of 4MHz is reached.

This allows a finer amount of travel per pulse, thus enabling positioning operation at a higher precision than before.

-

Differential input:Max. input frequency ≦ 4.0[MHz]

-

Open collector input:Max. input frequency ≦ 200[kHz]

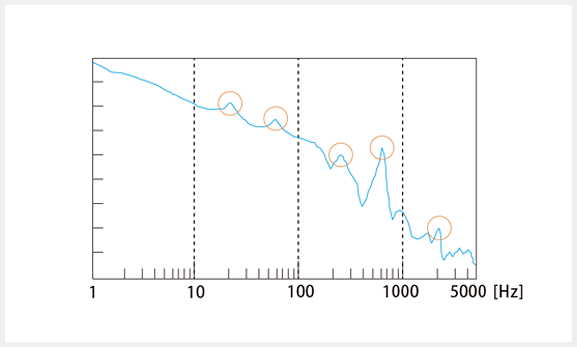

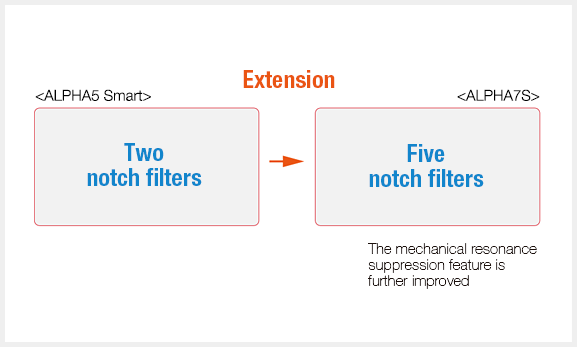

The Notch Filter Feature Suppresses the Resonance of the Machine

Now five notch filters are incorporated instead of two, further improving the machine resonance suppression feature.

The Motor Status can be Monitored from the Host Controller

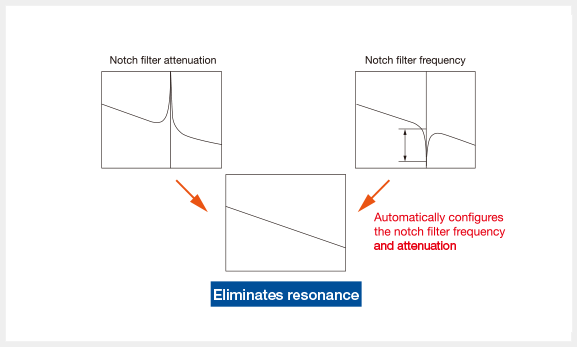

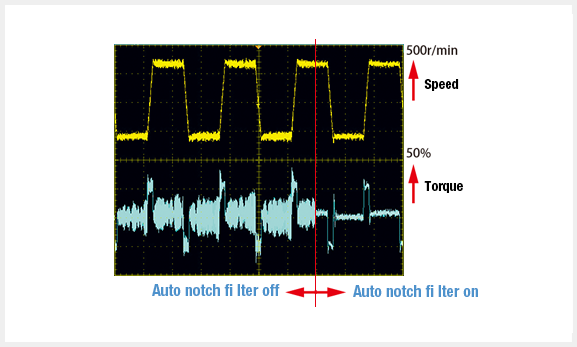

The system detects machine resonance and automatically configures the notch filters. While the auto notch filter feature is on, the system constantly performs detection and calculation, thus being able to respond even to moment-to-moment changes in resonant frequency.

One of Three Motor Stop Methods can be Selected

You can select “rapid deceleration stop”, “DB stop”, or “coast-to-stop” when an alarm occurs, when the main power is off, or when the servo-on signal is off. Since limiting output torque at desired value is possible even if rapid deceleration stop is selected, impact shock to the machine can be reduced.(Note)

-

Note

-

However, it is enabled when the control power supply is input.

A Homing Program can be Easily Configured

Several homing features allow simple configuration by just combining servo parameters.

Interrupt Positioning Feature

A fixed amount of movement is possible after detecting the mark signal, thereby enabling highly accurate mark operation.

It can be used for positioning operation by detecting the mark signal of the material, or for stopping after moving a certain amount in the last stage when there is wobble or slippage in the mechanical system.

Design and Features

The design and features reduce the need for maintenance.

Design and Features that Reduce the Labor of Maintenance

Easily Analyze the Cause of Alarm Occurrence

When an alarm occurs, the system displays the content of the alarm as well as related data such as the speed and torque at the time of alarm occurrence. This allows you to accurately analyze the cause of the alarm.

Life Prediction and Preventive Maintenance Features

You can check the status of the servomotor from the controller, so you can perform maintenance at the appropriate time. In addition, the system predicts the life for the following consumables and sends the data to the host controller for proactive failure prevention.

-

Battery

-

Main circuit capacitor

-

Cooling fan

Long Life Design of Servo Amplifier Parts

The design life of long-life parts has been further extended:10years for electrolytic capacitors and cooling fans. In addition, the design life of the battery is approximately 35,000hours.

(Retention time with the power supply shut off)

-

Note

-

The use conditions are as follows.

-

mbient temperature: 30°C(annual average)

-

Load factor: Up to 80%

-

ate of operation: Up to 20hours/day

The Environmentally Resistant Servomotor can be Used in an Environment with Exposure to Water and Dust

The servomotor is by default compliant with IP67(Note) defined by the International Electrotechnical Commission (IEC). It has Class 6 dust resistance and Class 7 water resistance, which means that it can be used in an environment with exposure to water and dust.

-

Note

-

Excludes shaft through-hole (also excludes connectors for GYS and GYB motors of lead wire type).

Compliant with Various Standards

Compliance with Overseas Standards and Laws

The ALPHA7S Series supports international standards.

<Certification Mark>

-

CE:

-

Compliant with EU (European Union) standards

-

UL:

-

Compliant with the U.S. safety standards

-

cUL:

-

Certifies the compliance of UL with CSA (Canada safety standards)

-

KC:

-

Korea’s nationally integrated certification mark

By Default Compliant with RoHS

Environmentally-friendly design compliant with the 10 hazardous substances(Note 1) of RoHS (EU’s Restriction of Hazardous Substances) and six hazardous substances(Note 2) of China RoHS (Management Methods for Controlling Pollution by Electronic Information Products).

-

Note 1

-

Lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyl (PBB), polybrominated diphenyl ether (PBDE), di-2 ethylhexyl phthalate (DEHP), butyl benzyl phthalate (BBP), di-n-butyl phthalate (DBP), diisobutyl phthalate (DIBP)

-

Note 2

-

Lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyl (PBB), polybrominated diphenyl ether (PBDE)

Harmonic Suppression

All models of servo amplifiers used by specific consumers are subject to the “Japanese Guideline for Suppressing Harmonics by Customers Receiving High Voltage or Special High Voltage”. All users required to apply guidelines must calculate equivalent capacity as well as harmonic outflow current based on these guidelines, and take appropriate measures if the calculated harmonic current exceeds the limit stipulated for the contracted wattage.

For information on how to calculate the harmonic current, use the following as a reference.

Reference material:Japan Electrical Manufacturers’ Association

-

Pamphlet “About Servo Amplifier Harmonic Suppression”

-

JEM-TR225 “Servo Amplifier Harmonic Current Calculation Method for Specific Consumers”

Providing the Best Solutions

We provide the best solution for each customer's usage.

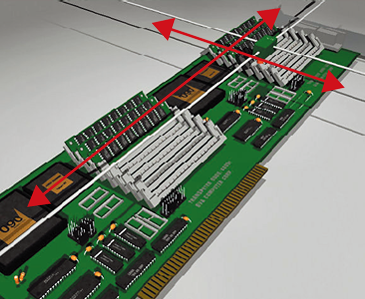

Inspecting instrument used in semi-conductor manufacturing equipment

01 Prober

Solution 1 : To Improve Productivity

-

Fine tuning and feed forward gain

Solution 2 : To Reduce the Vibrations of the Machine

-

Auto damping control and anti-resonant frequency for damping

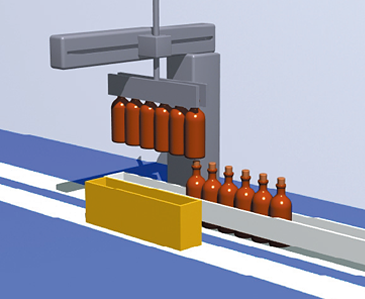

Used to take out formed products and convey workpieces

02 Takeout Robot

Solution 1 : To Reduce the Vibrations of the Machine

-

Auto damping control and anti-resonant frequency for damping

Solution 2 : To Suppress the Resonance of the Machine

-

Tuningless and notch filter features

Solution 3 : To Prevent Objects from Being Caught in the Machine

-

Interference detection feature

Used to fill or wrap food or chemical

03 Vertical Wrapping Machine

Solution 1 : To Eliminate Defective Workpieces by Synchronizing the Feed, Seal, and Cut Axes

-

Interpolation operation mode and feed forward control

Solution 2 : To Cut the Material at the Position of the Reference Mark

-

Enable interrupt input

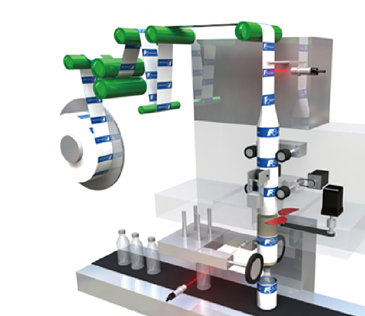

Used to wrap labels around bottles

04 Label Wrapping Machine

Solution 1:To Improve Productivity

-

Fine tuning and feed forward gain

Solution 2:To Cut the Material at the Position of the Reference Mark

-

Enable interrupt input