FRENIC-Lift(LM3S)

Product information

Dedicated design optimized for passenger elevators,

featuring built-in full-capacity braking circuit, rescue operation mode, and more

Dedicated design optimized for passenger elevators

Comes standard with built-in full-capacity braking circuit that contributes to space and cost savings in the control panel.

-

Standardly supports sine wave encoder (1Vpp) and serial encoder (EnDat2.1, Biss-C).

-

Standardly supports pulse output for connection to host controllers.

Rescue operations

During rescue operations, the AC Drive is operated (for braking) with a single-phase 200 V or battery-powered power supply to enable movement to a door area.

-

Note1

-

Only when using serial encoder (EnDat2.1, Biss-C)

-

Note2

-

Requires input of the voltage specified for the control power supply auxiliary input.

-

Note

-

During rescue operations, braking operations are implemented.

For details, refer to the User’s Manual.

Supports various motor combinations.

Contributes to improvedelevator ride quality by improving encoder detection accuracy.

Improves AC Drive control performance

The current response (ACR) of the AC Drive is 500 Hz. Improves detection accuracy at very low speeds with a sine-wave encoder.

Reduces rollback

Reduces rollback via improved performance. Improves ride comfort.

Improves encoder detection accuracy

Improved encoder detection accuracy enhances imbalance load compensation performance.

Capable of simplifying load cells.

-

(Note)

-

Only when incremental signal uses a sine wave encoder

Customizable logic functions

The FRENIC-Lift (LM3) Series also features the customized logic functions of the FRENIC-Ace (E3)/MEGA (G2) Series.

PC loader

Flexible development environment

Enables intuitive programming with PC loader support. Function blocks (FBs) created by users can be exported/imported and shared with other users. FBs can also be given a control number and can be password locked to conceal their internal logic.

Supports various combinations

Supports various encoders and motors combinations.

Standardly supports sine wave encoder (1Vpp) and serial encoder (EnDat2.1, Biss-C).

Supprted as standard

Synchronous motor

High-speed sensor-equipped vector control

Induction motor

High-speed sensor-equipped vector control

Induction motor

V/f Control Dynamic torque vector control

-

Note

-

Does not support hole sensor UVW and 4-bit gray code. Does not support high-speed sensorless vector control

Optional

PG interface card OPC-LM-PG3

Synchronous motor

High-speed sensor-equipped vector control

Induction motor

High-speed sensor-equipped vector control

-

Note

-

When driving a synchronous motor combined with a pulse encoder, the inverter determines the magnetic pole position after detecting the Z phase.

Password function

Comes with a password function to protect AC Drive parameters.

Locks parameter changes to prevent unintended parameter changes.

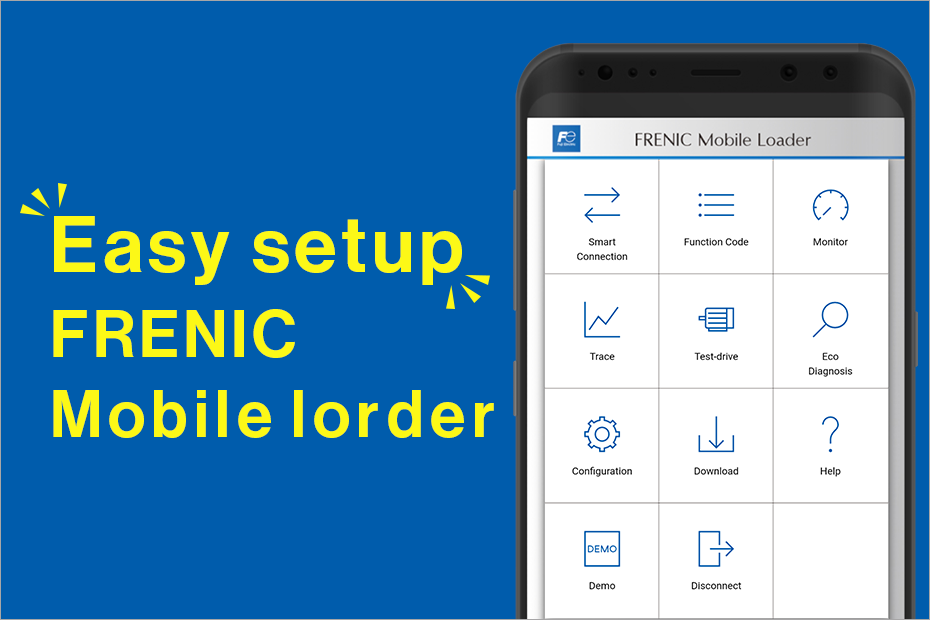

Improves work efficiency with simplified wiring and easy setup.

Features safe and reliable preventive and predictive maintenance functions

Equipped with USB port

Comes standard with USB port (Mini-B) for direct communication between AC Drive and PC. Capable of writing and reading parameters to and from the AC Drive using only bus power.

PC loader

Capable of directly connecting to a PC via USB to edit and monitor AC Drive parameters.

Easy function code changes

“Edit”, “Read”, “Transfer”, “Compare”, “Initialize”, and “Store data” for function codes.

Confirm with waveform

Displays a trace of the present status of current, voltage, and digital terminals as analog and digital waveforms. Capable of saving and loading trace data.

What is the present status?

Displays meter values of operating conditions in real time. Capable of displaying trip history, I/O status, and serviceable parts status.

Preventive maintenance and predictive maintenance

The keypad and PC loader make it easy to check the status of equipment and detect problems before they occur, helping to reduce production equipment maintenance time and downtime.

Long life expectancy (main components)

Many of the serviceable parts inside the AC Drive have been designed to meet customer equipment maintenance cycles.

Standards compliance

Compliant with overseas safety standards.

AC Drives (Low Voltage) Support

Download documents

Column

Understanding application, benefits, basic structure, case study, types, and Fuji Electric's inverters with this video.

December 27,2021

Understanding the basics: Differences between inverters and converters

January 20,2021

How and what does an inverter take control of? A brief explanation to grasp the basic structure.

January 20,2021

The fundamentals of inverters and their uses.

January 20,2021