Sustainability

Employee Health and Safety Management

Health and Safety Policy for Eliminating Workplace Accidents

Health and Safety Basic Policy

Employee health and safety is a top management priority. In line with the Health and Safety Basic Philosophy of putting that health and safety of workers takes precedence over everything else, we formulated the Basic Policy on Health and Safety, and have declared it to all business sites in Japan and overseas.

-

1.

Health and safety is one of the most important tasks of corporate management at Fuji Electric. High-quality health and safety activities are practiced to make the workplace safe and comfortable, eradicate industrial accidents and prevent mental and physical diseases.

-

2.

Applicable laws and regulations, and autonomous standards established by the Company, individual business offices and departments shall be observed. Health and safety activities sticking to the basics shall be exercised at all times.

-

3.

All individuals involved in the business of Fuji Electric shall participate in the voluntary health and safety activities as a team and enroot safety culture in the workplace in order to ensure their own health and safety.

-

4.

Health and safety activities focusing on the employees’ health and safety are pursued aggressively in all businesses we conduct. By publicizing these activities, we contribute to creation of a safer, securer and more comfortable society.

Company-wide Health and Safety Management Policy and Yearly Slogan (FY 2025)

Every fiscal year we formulate the Company-wide Health and Safety Management Policy, which identifies issues and specific action items based on the Health and Safety Basic Policy, and to further raise employee awareness we solicit ideas from them to create a health and safety yearly slogan.

The Company-wide Health and Safety Management Policy is shared with all employees through our business sites and becomes the cornerstone of health and safety activities for the fiscal year at the head office, branches, factories and local construction sites. In addition to domestic subsidiaries, the policy is delivered to overseas subsidiaries in English and in Chinese and we cultivate within all employees the ideas of "safety culture".

In fiscal 2025, we established the following as the "Company-wide Health and Safety Management Policy" and "Health and Safety yearly Slogan," and will work towards ensuring safety and preventing occupational accidents.

-

1.

Zero work-related disasters

-

2.

Zero work-related illness

-

3.

Zero traffic accidents

-

1.

Occupational Safety

-

1.

In order to prevent occupational accidents caused by unsafe behavior, all employees in the workplace should work together to prevent occupational accidents through daily safety guidance provided by managers and by verbally communicating with each other in the workplace.

-

2.

Promote risk assessments led by top management with everyone involved, including indirect departments, to minimize risks in the workplace by ensuring essential safety and implementing engineering measures for dangerous and hazardous work. In addition, if any risks remain, establish countermeasures and comply with them.

-

3.

In the event of an occupational accident, top management takes the lead in thoroughly investigating the cause, and then takes effective measures to prevent a recurrence and deploys the measures throughout other departments to prevent similar accidents. In addition, if any risks still remain, rules for work methods and procedures should be established and observed.

-

4.

When performing non routine work, do not make decisions on your own, but always discuss with a manager, supervisor, etc. regarding work methods and procedures, and ensure that safety is confirmed while the work is being performed.

-

5.

Implement safety and health training in a systematic manner and keep a record of the training after confirming that the trainee has understood and mastered the subject matter. In addition, provide daily safety and health guidance especially to workers who handle dangerous or hazardous substances and workers with less experience.

-

6.

Workers should follow the rules, perform risk prediction (kiken yochi or KY) before starting the work, confirm the work procedures in advance, and use pointing and calling. Managers (supervisors, etc.) should provide daily guidance and supervision.

-

7.

Prevent accidents and illnesses by improving the workplace environment, distributing and using protective equipment, and properly allocating workers, taking into consideration the declining physical functions of aging workers and their past medical histories.

-

8.

Enhance measures to prevent heatstroke in advance such as by improving the working environment, utilizing wet bulb globe temperature (WBGT) meters, and wearing air-conditioned clothing, so that the physical condition of workers can be controlled precisely and thoroughly.

-

-

2.

Occupational Health

-

1.

Thoroughly manage each of the three occupational safety controls (working environment control, work control, and health control) to prevent work related illnesses.

-

2.

Conduct a risk assessment in advance using safety data sheets (SDS), and based on the results of the risk assessment, implement risk reduction measures before performing the work.

-

3.

The results of the working environment measurements shall be based on the first control category, and in the case that they are the second or third control category, efforts shall be made to continually lower the control category.

-

4.

Actively implement company-wide health promotion activities to prevent and improve lifestyle related diseases, prevent mental health disorders, and maintain and promote the health of older workers.

-

-

3.

Traffic Safety

-

1.

Safe driving managers and heads of departments should manage and supervise the appropriate use of business vehicles in accordance with laws and standards.

-

2.

Safe driving managers should continuously educate qualified drivers of business vehicles about safe driving by providing them with various types of training and using accident case studies (dashcam drive recorder videos).

-

3.

Safe driving managers should thoroughly check for the presence of alcohol (such as by using a breathalyzer), as well as the physical condition, and whether the alcohol level is in compliance with laws and regulations and record the result. In addition , thoroughly check the state of driver fatigue and the appropriateness of operation plans and take necessary measures to prevent fatigued personnel from driving.

-

4.

Drivers should take good care of their physical condition and observe the seven rules of safe driving to avoid the risk of accidents.

-

5.

Passengers should participate with the driver in checking for safety.

-

Don't get used to anything. Don't omit anything. Don't let your guard down. Don't forget the basics. Zero Disaster Workplace.

Occupational Health and Safety Promotion System

Fuji Electric Co., Ltd., established the Health and Safety Promotion Committee, made up of officers in charge of labor relations and top management at all operating sites at the pinnacle of the Fuji Electric, and it sets the Company-wide direction of occupational health and safety management while also overseeing specific activities. The committee meets annually to determine the Company-wide Health and Safety Management Policy and a health and safety yearly slogan for each New Year while summarizing various factors, including the number of occupational and business automobile accidents in the previous year. It also steadily implements the PDCA cycle to ensure Company-wide safety and health (Implementation rate 100% for fiscal 2024).

In response to the Company-wide Policy, we established management policies, regulations, and standards for both ongoing operations and fixed-term projects, including new ventures at our plants, head office, and divisions according to their specific environments and attributes. We operate under an optimal safety and health management system PDF(74KB) based on the PDCA cycle for safety and health activities, which sets out requirements for the ideal state of safety and health management, including the development of management systems and various activities such as risk assessment. Each organization implements rigorous top-down command and control. We also conduct health and safety audits through safety departments across the Company. Emphasis is placed on bottom-up functions that reflect the real voices of workers in the field. Moreover, we work closely with our labor union to promote optimal occupational health management at each site.

Additionally, in fiscal 2024, 3 out of 36 companies (8.3%) in the Fuji Electric Group (2 out of 9 domestic consolidated subsidiaries and 1 out of 27 overseas consolidated subsidiaries) have acquired international certifications such as ISO45001 and OSHMS.

Initiatives to Ensure Occupational Health and Safety

Fuji Electric Health and Safety Conference

In accordance with our Corporate Mission we hold the Fuji Electric Health and Safety Conference each year with participation from representatives of factories, head office, divisions, labor union, affiliated companies, and partner companies. At the conference, attendees pledge to develop and maintain safe, secure, healthy, and positive workplaces.

The aims of the conference are to promote a “culture of safety” in which each and every employee always strives to prevent work-related accidents, and to foster a heightened awareness across the Fuji Electric Group as a team about prioritizing safety and health.

The fiscal 2025 conference was attended by many occupational safety and health personnel, including those from affiliated and cooperating companies. During the event, messages from top management and the labor union were delivered, and we reviewed our 2024 safety and health activities while presenting the Safety & Health Management Policy for 2025. These discussions have been incorporated into the safety and health plans of each site, including factories, headquarters, and branch offices.

In fiscal 2025 the entire company will continue promoting health and safety activities to achieve its health and safety targets.

Factory Safety and Health Reviews and Business Vehicle Management Assessments

We conduct reviews of factory safety and health practices on a biennial basis, as well as assessments of business vehicle management, in collaboration with our corporate safety departments to ensure compliance and oversight. These reviews include a desk-based compliance check using a common checklist for laws and internal regulations, as well as on-site inspections to provide guidance and recommendations.

Additionally, similar assessments are carried out at our consolidated subsidiaries to promote group-wide adherence to safety and legal standards.

Ensuring Safety at Overseas Bases

At the overseas bases of consolidated subsidiaries, we apply the Company-wide Health and Safety Management Policy and health and safety regulations and provide safety training materials, in an effort to achieve management levels equivalent to Japan. We also work to conduct health and safety activities that reflect the laws, cultures and customs of each country with a Company-wide system that involves coordination between the safety division and personnel, legal, overseas sales and industrial health divisions

Inspections from a third-party perspective are an effective way to uncover risks lurking in familiar work processes. We therefore believe it is vital to continue conducting systematic safety patrols and risk assessment at business sites, including those of Group companies.

In fiscal 2024, our company launched a mutual risk assessment program for factories, where the corporate safety department collaborates with safety and health managers at various plants. This initiative involves not only evaluating the activities related to risk assessment itself but also conducting joint on-site inspections. By observing the workplaces together, we have achieved significant results, such as discovering previously unnoticed risks and proposing new risk mitigation measures, ultimately leading to the improvement of working environments.

Safety Patrols for Subcontractors

Realizing its responsibility as a company that uses subcontractors, Fuji Electric conducts thorough patrols of plant construction sites at which it is responsible for the safety of a large number of subcontractors based on local health and safety diagnosis standards. Through these patrols, we seek to secure, maintain, and enhance compliance and health and safety.

Holding Health and Safety Training

In addition to legally mandated health and safety training, Fuji Electric also provides training through open seminars, which are even open to employees of subsidiaries and affiliates; new employee training; and training and drills conducted on the business site and factory level. In addition, leader and occupational health and safety manager training is provided for the floor leaders of affiliates. In this manner, we organize and hold health and safety training based on highly practical curriculum throughout each year.

Status of Work-Related Accidents

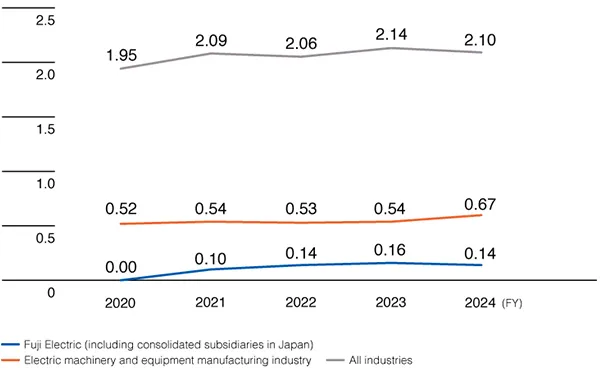

Accident frequency rate (Rate of lost-worktime injuries):

Number of accidents resulting in casualties per 1 million work hours=

Number of accidents resulting in casualties / Aggregate work hours × 1,000,000

Number of accidents resulting in casualties = Accidents results in fatalities + Accidents requiring time off from work (excluding accidents not requiring time off from work)

-

Scope

-

Fuji Electric Co., Ltd. and Consolidated Subsidiaries in Japan

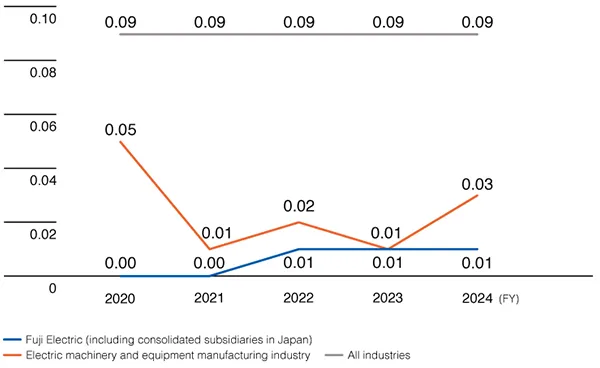

Accident severity rate: Number of lost workdays per 1,000 total hours worked = Total lost workdays / Total actual hours worked × 1,000

-

Scope

-

Fuji Electric Co., Ltd. and Consolidated Subsidiaries in Japan

-

Scope

-

Fuji Electric Co., Ltd. and Consolidated Subsidiaries in Japan

Accident-free record

The Kawasaki Factory achieved the Second Class No-Accident Record, while the Tokyo Factory and Otawara Factory achieved the First Class No-Accident Record. All three factories were commended by the Ministry of Health, Labour and Welfare. We will continue our efforts to create safer and more comfortable workplaces, and to eliminate workplace accidents.

Award for Excellent Safety Leadership

Hideo Miyajima, a frontline supervisor at Matsumoto Factory, received the Minister of Health, Labour and Welfare Award for Outstanding Safety Leadership in FY 2024. He has achieved a continuous 18-year record with no lost-time accidents or injuries. He is also actively pursuing qualifications such as Level 2 Quality Control (QC) Certification and First-Class Hygienist.

"We are deeply honored to receive the Minister of Health, Labour and Welfare Award for Outstanding Safety Leadership. This achievement is the result of a long-term, company-wide commitment to safety, with all employees maintaining a high safety consciousness and continuously working toward a no-accident workplace. We will continue to strive for even higher safety standards, with this recognition serving as motivation for ongoing improvement."

Health Management and Mental Healthcare

In addition to legally mandated regular health checks, active efforts are being made to prevent lifestyle-related diseases through measures such as adopting the latest screening items and methods and making professional health consultations available.

In addition, we are developing systems and environments in which all employees can work with good health and vitality. Under the Company-wide health promotion system that actively supports each employee's efforts to maintain and improve their health, we are propelling company-wide health promotion activities.

In fiscal 2024, we held e-learning programs to prevent and ameliorate lifestyle-related diseases and mental health problems, as well as e-learning on mental and physical health education for all employees (Number of participants: 19,551) , as well as education for learning how to care for subordinates (line care) for senior managers in positions of leadership in the workplace (Number of participants: 2,793) . In addition, we are encouraging medical checkups for those with severe lifestyle-related diseases, eliminating work-related interruptions to treatment, strengthening health guidance for those who are in the preliminary stages of such diseases, and providing health guidance for those with inappropriate lifestyles.

Our stress check system, which is designed to prevent mental health problems among workers, has become widespread among our employees (Number of people taking the stress check in 2024: 17,140). We also conduct collective analysis on an ongoing basis and use the results to improve our workplaces. In addition, we provide mental health education from various perspectives, including sleep education and stress coping methods, according to the characteristics of our business bases—factories, head office, and divisions—to emphasize self-care and line care.

Promoting and maintaining the health of older employees is an integral part of our company-wide health initiatives. In fiscal 2024, each business site implemented measures tailored to its specific circumstances. Furthermore, by sharing successful examples of activities among our sites during the first half of the year, we have encouraged each site to effectively adopt and enhance best practices from other locations, thereby further energizing health promotion efforts across the company.

Furthermore, we have set up a 24-hour health hotline to provide physical and mental health counseling to employees and their families at any time while strictly protecting their privacy.

We are committed to protecting employees on overseas business trips and assignments from catching infectious diseases, such as type-A hepatitis, tetanus, HIV/AIDS, tuberculosis, malaria, and COVID-19. To this end, we implement medical examinations and vaccinations before they go abroad, and provide a wide range of information on infection prevention measures via our website and other resources.

Starting from fiscal 2020, we also conduct stress checks on employees posted overseas to prevent mental health problems from occurring.