Sustainability

Promoting CSR Activities with Suppliers

-

Philosophy concerning Promoting Sustainable Procurement in the Supply Chain

-

Initiatives for Achieving Sustainable Procurement with Our Suppliers

-

Support for Raising Awareness among Suppliers

-

Response to Conflict Minerals

-

Rejecting Any and All Ties with Antisocial Forces

-

Occupational Health and Safety in On-Site Construction Work

Philosophy concerning Promoting Sustainable Procurement in the Supply Chain

The Fuji Electric Code of Conduct stipulates that we “Respect and value our business partners,” and we believe it is important to be a company with high social value by building a supply chain that supports a sustainable society.

One of the commitments under Fuji Electric’s Environmental Vision 2050 is to “realize a recycling-oriented society.” From the perspective of global environmental protection, we actively promote green procurement by sourcing materials with low environmental impact from suppliers who actively engage in environmental protection activities.

Initiatives for Achieving Sustainable Procurement with Our Suppliers

We are expanding “Fuji Electric’s CSR Procurement Guidelines” globally, while also aiming to build responsible supply chains with our suppliers in Japan and abroad. These Guidelines were formulated for the purpose of sharing our concept of CSR with our suppliers and having them put it into practice.

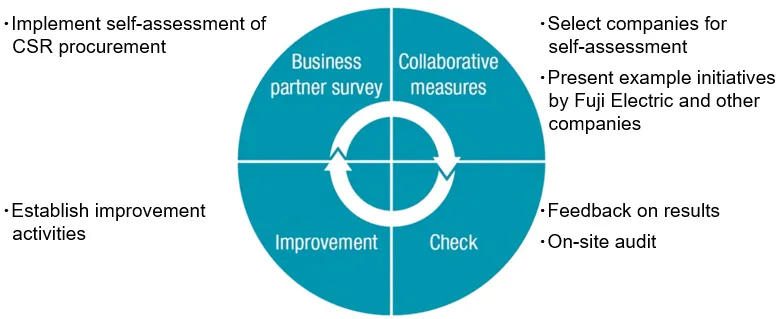

We ask our suppliers to conduct the self-assessment of CSR procurement in accordance with the Fuji Electric CSR Procurement Guidelines. This selfassessment helps us see a clear picture of CSR initiatives in our supply chain. Furthermore, in providing their answers to the questions in the assessment, our suppliers gain a better understanding of Fuji Electric’s CSR philosophy and what we would like them to comply with and practice. If any supplier seems to need more efforts in terms of CSR, we work with them so that they will achieve a higher level of CSR, thereby reducing risks involved in CSR in a supply chain.

From October 2022, we require new suppliers to conduct a CSR self-assessment to understand and evaluate the status of their CSR efforts.

Fuji Electric’s CSR Procurement Guidelines

From the perspective of reducing CSR risks in the supply chain, we estblished the "Fuji Electric CSR Procurement Guidelines" as a summary of the approach and specific examples of initiatives that we would like our suppliers to observe and put into practice. In formulating the guidelines, we referred to the code of conduct of the Responsible Business Alliance (RBA), a corporate alliance that promotes CSR in global supply chains, and the "Responsible Business Conduct Guidelines" of the Japan Electronics and Information Technology Industries Association (JEITA).

Fuji Electric's Green Procurement Guideline

In promoting green procurement, we established our Green Procurement Guideline and confirmed the following two points with our suppliers.

-

1.

Management status of chemical substances contained in products

-

2.

Status of chemical substances contained in delivered materials

In order to properly manage chemical substances throughout the supply chain, we request the cooperation of our suppliers in using the Green Procurement Guideline to investigate chemical substances contained in products. Furthermore, we recommend management based on the “Guidelines for the Management of Chemicals in Products” established by the Joint Article Management Promotion-consortium (JAMP), and request that JAMP’s chemSHERPA* be adopted as a common management tool to facilitate the investigation of substances contained in products.

-

*

-

chemSHERPA is a support tool recommended by the Ministry of Economy, Trade and Industry (METI) that integrates JAMP and the former Japan Green Procurement Survey Standardization Initiative (JGPSSI) to manage and communicate information on chemical substance content throughout entire supply chains (from upstream to downstream), including those of trading companies, for each product.

<FY2024 updates>

-

1.

Added “Country-Specific Prohibited Substances” to our controlled substances list.

-

2.

Added a “Survey Sheet on France’s Packaging Materials Mineral Oil Ink Restrictions” to the required documents/data list.

-

3.

Added “Reporting on Country-Specific Prohibited Substances” to the product chemical content survey.

Fuji Electric's Carbon Footprint Procurement Guidelines

To help achieve carbon neutrality under our Environmental Vision 2050, we created guidelines that ask our suppliers to cooperate on carbon footprint (CFP) initiatives. These guidelines support understanding of our decarbonization efforts and promote visibility of greenhouse gas (GHG) emissions across business activities.

Built on the Fuji Electric Corporate Code of Conduct, our Basic Environmental Policy, and the Fuji Electric Purchasing Policy, and informed by the “Carbon Footprint Procurement Guidelines” issued by Japan’s METI and MOE (March 2023), the document outlines the CFP actions we ask suppliers to take, along with practical steps and examples.

The Japanese edition of this guideline has been finalized and is available. The English and Chinese editions are currently in preparation and will be made available on this page as soon as they are ready.

Support for Raising Awareness among Suppliers

We evaluate and analyze the sustainability initiatives of our suppliers for the purpose of engagement with them and risk management.

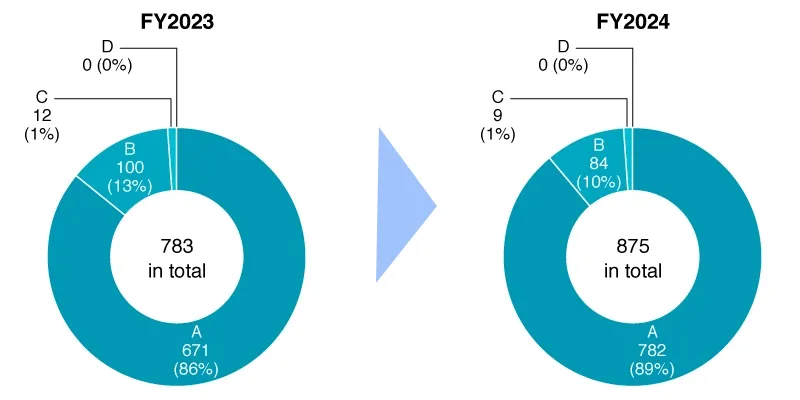

In FY2024, we asked 875 key suppliers—728 in Japan and 147 overseas—out of roughly 6,100 group suppliers to complete our self-assessment. These companies represent the top 80% of our purchase value over the past three fiscal years (FY2021–FY2023). Based on the Fuji Electric CSR Procurement Guidelines, suppliers conducted self-checks in the following areas:

-

Human rights and labor

-

Occupational health and safety

-

Environment

-

Fair business practices

-

Quality and product safety

-

Information security

-

Business continuity planning (BCP), etc.

Where improvements were needed, we held individual meetings with 12 suppliers to deepen understanding of CSR and to confirm progress. Since October 2022, new suppliers have also been required to complete the CSR self-assessment so we can make a well-rounded evaluation that includes their CSR status. We will continue open dialogue with our suppliers and work together to build a supply chain that supports a sustainable society.

CSR Procurement Audits: current status

In FY2024, we conducted on-site audits at 17 suppliers and confirmed that actual practices aligned with their self-assessment responses.

For FY2025, we plan on-site audits at 20 suppliers.

Through these visits, we aim to strengthen communication and drive two-way, complementary improvement activities.

Training On-Site CSR Auditors

To expand on-site audits, we are actively developing internal auditors.

In FY2024, 12 new auditors were certified. In FY2025, we plan to certify 13 more. This will allow us to assign two auditors per site, enabling more effective and efficient audits.

<Auditor certification process>

-

Complete all sessions of the auditor training course

-

Pass the certification exam (score of 70 or higher)

-

Complete on-the-job training during an on-site audit

Communication with Business Partners

Once a year, we invite suppliers who have made significant contributions to our business to attend a “business policy explanatory forum.” We use this as an opportunity to further deepen relationships of mutual trust with suppliers in recognition of the valuable support we receive from them.

In fiscal 2024, we recognized 96 suppliers as best partners, and also held an awards ceremony for suppliers who have achieved particularly outstanding results for our business.

Every year, each factory and business site holds a purchasing policy briefing session for the local suppliers. In addition to sharing our CSR procurement guidelines, we communicate our key procurement measures, as well as our policies and initiatives on the environment, quality, compliance, and other areas, thereby enhancing the effectiveness of sustainable procurement activities.

To advance our Environmental Vision 2050, we have launched joint decarbonization initiatives with suppliers.

We held briefing sessions for 880 key suppliers in Japan and overseas to share our approach and actions for reducing GHG emissions. We also conducted a survey to understand each supplier’s decarbonization efforts.

In FY2025, we plan to tailor support to supplier maturity levels, including decarbonization management briefings, e-learning on GHG reduction, and one-on-one interviews.

We also plan study sessions to help suppliers collect primary data for carbon footprint calculations.

We promote communication and awareness-building with suppliers through our participation in the “Declaration of Partnership Building” initiative.

Response to Conflict Minerals

Fuji Electric has a policy of not supporting acts that indirectly violate human rights through its supply chain. Based on this policy, Fuji Electric and its affiliates have worked to ban the use of minerals associated with the funding of armed insurgents, human trafficking, forced labor, child labor, abuse, war crimes, and other human rights violations. These minerals include tin, tantalum, tungsten, gold, cobalt, mica and its derivatives produced in the Democratic Republic of the Congo or areas of conflict in surrounding countries.

In February 2014, we became an official member of JEITA's Responsible Minerals Trade Working Group. In this role, we promote effective activities in collaboration with industry groups, including by collecting the latest information of RMI on conflict minerals.

-

*

-

RMI:Responsible Minerals Initiative

Rejecting Any and All Ties with Antisocial Forces

Fuji Electric continues to reject any and all ties with antisocial forces. Prompted by the growing sophistication of financing techniques adopted by antisocial forces in recent years, the government of Japan has announced specific guidelines to combat these techniques. Fuji Electric and its associates have concluded memoranda of understanding concerning the rejection of ties with antisocial forces with all new and continuing suppliers in Japan. At the same time, we respond to requests from customers, such as those asking us to conclude similar memoranda, in good faith.

Occupational Health and Safety in On-Site Construction Work

Fuji Electric outsources on-site construction and installation of power generation facilities and industrial equipment to external professionals. The Company undertakes various activities recognizing its responsibility in the management of occupational health and safety with respect to construction work.

Danger prediction meetings and tool box meetings are held to discuss and predict areas of potential risk, and clarify safety requirements for each work process. In addition, inspections of tools and equipment, onsite safety patrols and other related activities are conducted on a daily basis.

Moreover, safety deliberation meetings with construction companies are organized for large-scale projects. Ongoing steps are taken to prepare occupational health and safety materials as well as to distribute occupational health and safety reports. At the same time, special education and training programs are regularly implemented for the handling of hazardous substances including hydrogen sulfide.

In accordance with the amendment of Enforcement Guidelines to the Construction Business Act in Japan, companies are required to instruct subcontractors to enroll in social insurance programs such as medical insurance and pension plans for their workers as part of their responsibilities as a principal contractor and to promote public social security.

Fuji Electric has begun confirming the social insurance enrollment status of subcontractors, and creating a related database, as part of its responsibilities as a principal contractor, beginning with construction work outsourced from November 1, 2012. We select subcontractors and provide guidance based on this information.