Sustainability

Risk Management

Fuji Electric is strengthening its risk management to maximize corporate value and minimize the potential impact of risks.

Basic Policies

Based on the Fuji Electric Risk Management Rules, the Company manages risks in a coordinated, systematic manner. We practice appropriate management and counter various risks that could affect Fuji Electric’s management in order to prevent risks from materializing (crisis situations), thereby minimizing the impact on management in the event that risks do materialize.

Risk Management System

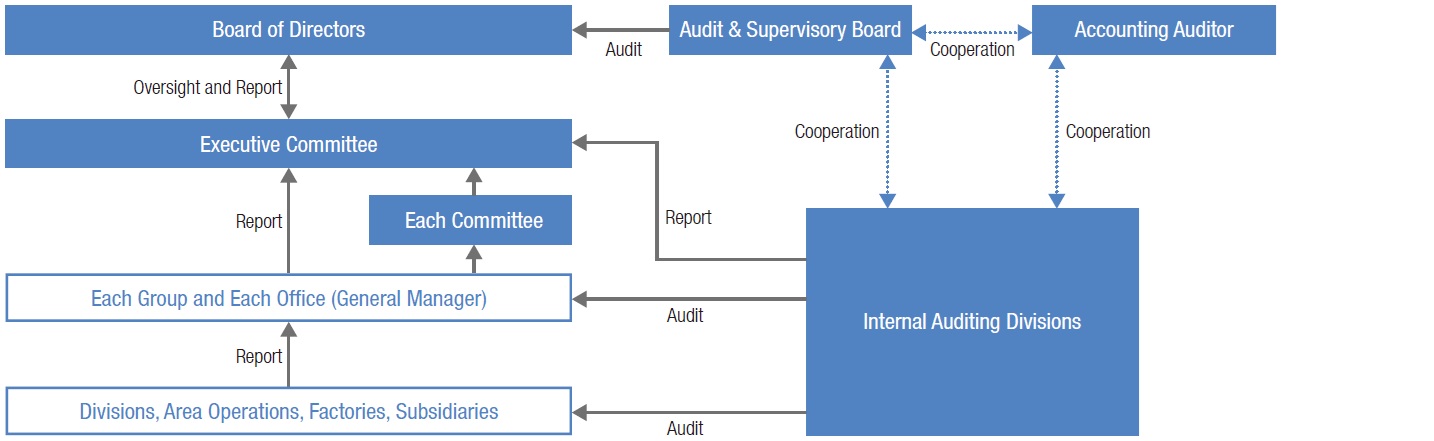

The Company’s business divisions and affiliated companies are responsible for managing risks related to their business activities as a part of their business duty, developing appropriate risk management systems, and implementing risk countermeasures.

Significant risks, such as those related to business plans and large-scale investments, are reported at the Executive Committee as appropriate to facilitate the sharing of information. We also have manuals in place to ensure that risks are steadily managed. We provide training in handling each type of risk and inform the whole Company about our efforts to manage risks through company magazines and other appropriate means.

The internal auditing divisions conduct regular audits to check whether each business division and affiliated company identifies and evaluates risks based on the Fuji Electric Risk Management Rules, defines countermeasure policies, and properly builds and operates management systems. In fiscal 2024, we conducted internal audits at 45 bases. No risks or inadequacies with the potential to seriously affect management were discovered.

Emergency Response

If an emergency arises due to a large-scale disaster or any other serious cause, we need to act to prevent the situation from becoming any worse and resolve the situation as soon as possible. Hence, we have guidelines in place on preparations for possible emergencies, an emergency contact network, and setting up an emergency task force.

Risk Management Process

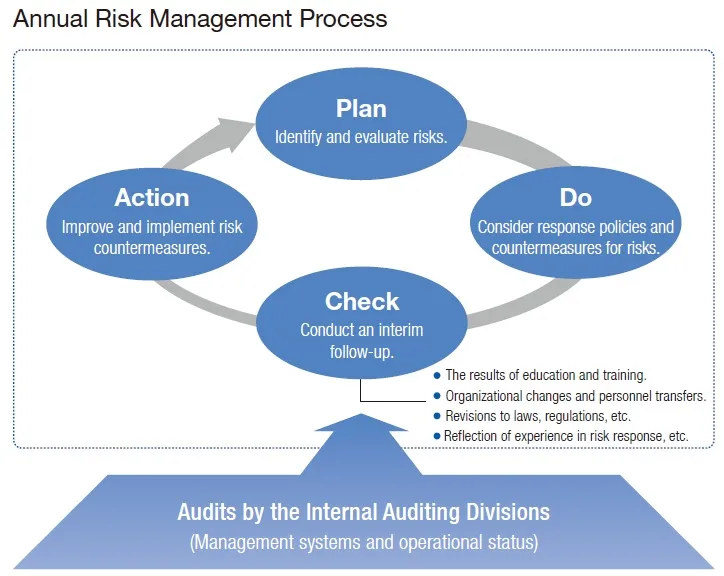

When annual budgets are formulated, the Company’s business divisions and affiliated companies gain an understanding of and evaluate risks related to their business activities.

Policies and countermeasures in response to risks (aversion, mitigation, relocation, retention, and so forth) are considered based on their impact on management and frequency of occurrence, and each division appoints a person in charge of policy and countermeasure execution.

We conduct an interim follow-up at the end of the second quarter to implement an annual evaluation of risk measures, including the results of education and training, and to reflect them in the risk management system based on revisions to laws, regulations, and other rules as well as our experience in responding to risks. In this way, we improve the measures for the next fiscal year.

The statuses of these management systems and operations are regularly audited by the internal auditing divisions.

We also conduct mid-year progress checks at the end of the second quarter of each fiscal year to improve and effectively implement risk countermeasures.

Responding to Natural Disasters and Accidents(BCP Efforts)

for active business

continuity efforts,

leading to the acquisition of

Resilience certification

In order to resume and continue the important businesses within the required time even when unforeseen situations such as large-scale natural disasters and accidents occur, we have formulated business continuity plans (BCPs), and are making efforts companywide for continuous improvement, based on the Fuji Electric Business Continuity Management (BCM) Rules.

In addition to formulating BCPs at the head office, factories, and area operations, which serve as contact points with customers, we have formulated BCPs for functions that are essential for business continuity, such as measures for early recovery and minimizing damage to IT systems, response to natural disaster risks in the procurement field, and multi-sourcing. Furthermore, we implement education and training based on the formulated BCPs and we are working to strengthen our business continuity capabilities by regularly evaluating the effectiveness of the BCPs and their management system once every half-year at the “Company-wide BCM Promotion Meeting” in order to make improvements.

Furthermore, to ensure reliable execution of emergency response and business continuity measures, we hold “Business Continuity Seminars” for business manager-level employees and “Disaster Response Headquarters Drills” at each base on an ongoing basis. Four times a year, we also conduct drills that simulate a situation in which the head office’s disaster response headquarters is non-functional due to a large-scale earthquake.

In recognition of these proactive business continuity initiatives, we have obtained and renewed the “Resilience Certification” as an organization that contributes to national resilience.

Contributing to Business Continuity through Stable Procurement

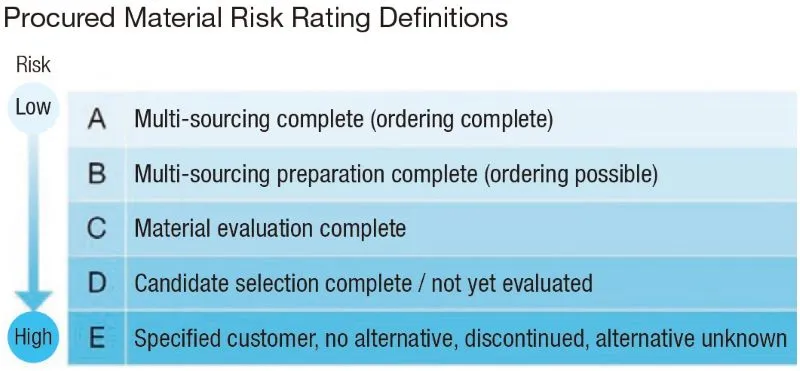

We conduct risk assessments for the approximately 200,000 parts and materials that we order on an ongoing basis and are promoting visualization of single-source items and transitioning to multi-sourcing. In fiscal 2024, we established multi-sourcing for approximately 85% of our procured items (a five-percentage-point increase from the previous fiscal year). In fiscal 2025, we will aim for a 90% multi-sourcing rate and promote the development of new suppliers to eliminate single-source items, aiming to build a resilient supply chain.

In Japan, we utilize a disaster prevention system that can identify business partners located in areas where special warnings on earthquakes or weather have been issued. We have established a system for quickly ascertaining whether our business partners have been affected and the impacts on our company, enabling us to promptly formulate countermeasures. We are expanding the scope of registration of this disaster prevention system to include secondary business partners, with the number of registered bases reaching approximately 12,000 in fiscal 2024. Meanwhile, in response to disasters occurring overseas, we conducted a trial of this same system in fiscal 2024. In fiscal 2025, we will proceed with a full-scale introduction targeting 200 bases, increase registration of overseas business partners, and further strengthen our global BCP.

Efforts to Improve Quality

As for quality, each year we formulate the High Reliability Activities Policy and apply it to each business division and factory to promote improvement activities. To enhance the degree of product refinement at the development and design stages, we are incorporating plans to acquire new technologies into our design reviews, in addition to the technologies our factories already possess. Furthermore, we are working to strengthen our quality management framework by re-examining our operational procedures.

In addition, at our production sites, we are automating visual inspections using image diagnosis powered by AI technology and are proceeding to digitize quality records. We utilize this data for statistical process control (SPC) and other methods to eliminate human error and the risk of equipment defects.

For process quality, regarding the management status of our manufacturing processes, in addition to the internal audits conducted at each factory, we also carry out mutual diagnoses by experts from other bases. To improve our quality control standards, we reflect the results and findings in our frameworks and rules.

Initiatives to Strengthen Project Management

Fuji Electric is committed to reducing the risks of incurring losses by strengthening project management in order to further enhance our corporate value through profit-oriented management.

To facilitate early identification of loss risks and predictive maintenance, we analyze the causes of major losses that have occurred and share them with relevant divisions within the company. We also implement measures to prevent recurrence and monitor such implementation.

In fiscal 2024, we managed the implementation status in collaboration with the relevant business divisions and corporate divisions to establish pre-order review rules for projects with high credit risk and to ensure thorough project progress management, including costs of ordered projects. We also regularly reported on and discussed these matters with management at Executive Officer meetings. In addition, we conducted training for our Japanese expatriates and locally hired staff regarding the practical guidelines and operational rules formulated to strengthen the level of management and to prevent losses at our overseas bases.

We will work to enhance training at our overseas bases, leading to further strengthening of project management and an even greater reduction in the risk of losses.

Information Security Measures

Efforts to Maintain and Strengthen Information Security

To properly manage as confidential information all asset value such as management, commercial and technical information and personal information held by Fuji Electric, the Company has redeveloped and rolled out policies and regulations related to information security based on the National Institute of Standards and Technology (NIST) Cybersecurity Framework.

Furthermore, we have also established management systems at Fuji Electric as well as Group companies in Japan and overseas, and we provide regular training to all of our employees, manage access to operating sites and offices, implement Internet device and computer security measures, and conduct annual inspections regarding the status of efforts taken by each workplace.

In addition, to respond to increasingly diversified and sophisticated cyber-security threats, we have incorporated the expertise of third-party specialists, and we endeavor to strengthen our computer security incident response team and security operation center (CSIRT/SOC), our monitoring of signs and information related to new cyberattacks, and our information-system defense and attack monitoring functions.

At our bases as well, we strive to improve our information security countermeasures based on the requirements of our business partners, related industry organization guidelines, market trends, and other factors, and in businesses for which public certification of information security management is required, two departments and two subsidiaries of Fuji Electric Co., Ltd. have acquired information security management system (ISMS) certification. Furthermore, concerning personal information protection, Fuji Electric Co., Ltd. and two of its subsidiaries have acquired the Privacy Mark certification.

In fiscal 2024, in addition to the Tokyo Factory and the Suzuka Factory, which obtained their certifications in fiscal 2023, the Kobe Factory, Hakko Electronics Co., Ltd., and Fuji Electric FA Components & Systems Co., Ltd. acquired certification for the international standard for control system security, IEC* 62443-4-1. The Fuji Electric Group will continue to promote certification acquisition.

-

*

-

International Electrotechnical Commission

External Certification Related to Information Security

Implementing Information Security Audits

Fuji Electric conducts internal audits as a part of efforts to lift the level of information security on a continuous basis. In fiscal 2024, internal audits were conducted at all of Fuji Electric's departments and divisions as well as 25 consolidated subsidiaries in Japan and 30 consolidated subsidiaries overseas.

For issues identified by the internal audits, the divisions and companies will create improvement plans and all of Fuji Electric, including its overseas sites, will work to continually improve.

Information Security Education and Training

Fuji Electric conducts regular information security trainings and works to improve information security awareness and knowledge among all employees.

Other affiliated 54 companies in Japan and overseas conduct their own respective information security education and training.

Coordination with Information Security-Related Organizations

Fuji Electric participates in or coordinates with the following information security-related organizations.

-

1.

Nippon CSIRT Association

-

2.

Japan Computer Emergency Response Team Coordination Center

Measures to Prevent Infringement of Intellectual Property Rights

As part of our intellectual property activities, we employ a system to monitor other companies’ patents on a daily basis to prevent any inadvertent infringement of patents held by third parties.

We also conduct compliance training for employees as part of our effort to prevent infringements.

With respect to our own technologies, we actively acquire patent rights to protect our business. Fuji Electric continues to address overseas intellectual property issues and implement measures against counterfeit products to minimize business risks related to intellectual property.