Forecasting and visualization

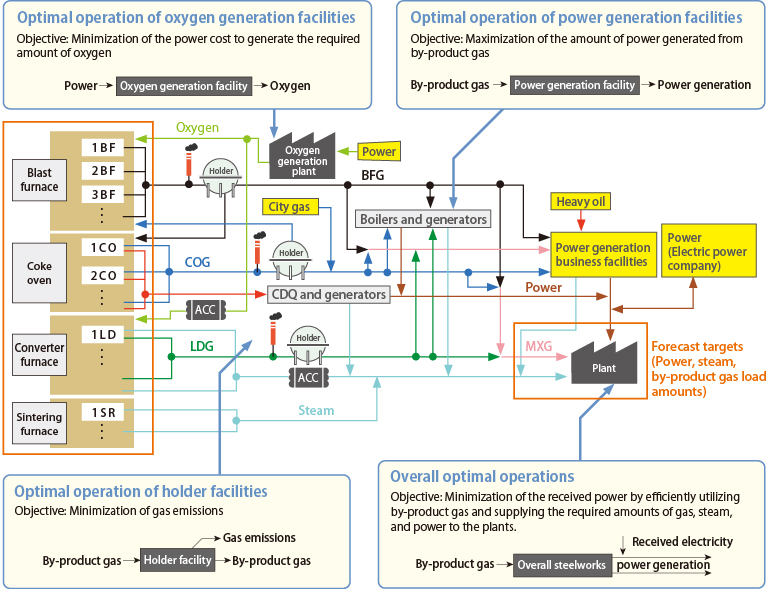

Forecasting and visualizing future fluctuations of energy (generation and usage amounts of by-product gas, power, and steam) make it possible to anticipate operations in advance and plan energy-saving measures.

-

Automatic correction of production and operation plans when differences arise with the operating condition of the site

-

Automatic creation of energy consumption units from actual data

-

Creation of accurate energy forecasting values

Accurately forecasting the amounts of by-product gas generated and used makes it possible to effectively utilize the gas holders and provide a stable supply of by-product gas for use by the facilities.

-

Monitoring the amount of power used by each production plant in the steelworks and forecasting usage from the production and operation plans, and outputting guidance when the amount of power received exceeds the contracted amount

Accurately forecasting fluctuations of the power load at each plant makes it possible to operate while purchasing and selling electricity within the contract terms.

-

Energy savings by minimizing power consumption from the forecast amount of oxygen required according to the operation planned for the facility

-

Operation support using operation guidance for understanding differences in the efficiency of multiple power generation facilities and obtaining maximum power generation from by-product gas

Accurately forecasting the amounts of oxygen and steam used by the facilities reduces the surplus production of the oxygen plants and surplus steam from the power plants.

Minimization of energy costs at steelworks by utilizing the latest optimization technologies (metaheuristics*, mathematical programming, etc.) based on forecast data (data per plant and data per energy source) calculated from supply and demand forecasts.

-

*

-

Metaheuristic: Obtaining an adequate solution at a certain level independent of a specific calculation problem

BF:Blast Furnace CO:Coke Oven CDQ:Coke Dry Quenching LD:Converter furnace SR:Sintering furnace ACC:Accumulator BFG:Blast Furnace Gas COG:Coke Oven Gas LDG:LD Gas MXG:Mix Gas