Solutions and Case Studies

The Untold Story of the Development of a PCS for High-Capacity Solar Power Generation.

-

Fuji Electric Boasts Second Highest Share in the Japanese PCS Market. Increasing Competitiveness through Higher Capacity and Miniaturization.

-

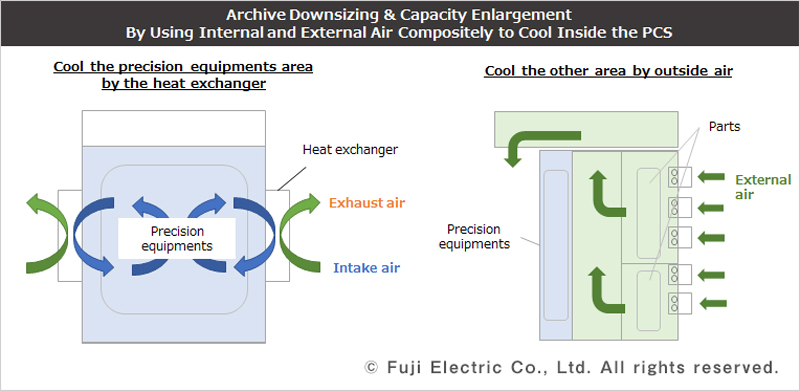

Achieving miniaturization through a combination of internal and external cooling.

-

Focusing on Southeast Asia, where demand is expected to grow. Contributing to the spread of clean energy.

Fuji Electric Boasts Second Highest Share in the Japanese PCS Market. Increasing Competitiveness through Higher Capacity and Miniaturization.

As global warming prevention measures become increasingly important, the expansion of renewable energy is growing in importance as well. One source of renewable energy is solar power, and one indispensable device for generating solar power is a power conditioning systems (PCS). A PCS is a device that converts the DC power generated by solar panels into AC power that can be used in people’s homes. A PCS’s conversion efficiency and capacity have a significant effect on the power generation efficiency of solar power generation facilities. In 2012, Japan started a feed-in tariff (FIT) system for renewable energy, prompting the construction of mega solar power plants. Fuji Electric has expanded its business with a high-efficiency PCS using power semiconductors produced in-house, and it currently boasts a share of about 15% in the Japanese market for PCSs of 100 kW or more in capacity (based on number of units shipped), ranking second in its group. But recently, Japan has completed a cycle of construction of mega solar power plants, so the aim behind the development of this high-capacity PCS was full-scale overseas expansion.

When aiming for overseas expansion, product cost competitiveness is an unavoidable problem. Given this, Fuji Electric's high-capacity PCS meets customer needs by increasing power density to achieve higher capacity and miniaturization. It boasts a capacity of 2500 kVA, the largest ever, and is 30% smaller than competitors' products and 40% smaller than the company’s conventional product. Its footprint of 1.1 m2/megawatt is also one of the smallest in the world.

Achieving miniaturization through a combination of internal and external cooling.

The key to achieving higher capacity and miniaturization was reviewing the internal board structure using the cooling technology Fuji Electric has developed so far. "The biggest issue when increasing capacity is the amount of heat generated by the equipment, which increases as more circuits are installed,” says Tetsuya Maeda, who is in charge of structural development in Fuji Electric's Electric Power Device Development Department. This product required proper cooling because the equipment generates heat in excess of 50 kW, and it needed to be operable even in environments with outside air temperatures of nearly 60°C. Miniaturization was also essential to achieving the cost targets, and it was difficult to design an internal board structure that allowed us to balance both. To arrive at the optimal solution, we ran simulations of over 10 different structural layouts and over 20 different temperatures and wind speeds." Despite these difficulties, through trial and error, Fuji Electric achieved both high capacity and miniaturization with a structure that combines internal and external cooling. Areas with heat-sensitive precision parts are cooled with a heat exchanger while other areas are cooled with outside air.

Another key feature is higher efficiency at low output. Normally, a PCS is equipped with three inverter circuits composed of power semiconductors and other parts, and it converts the DC power generated by solar panels into AC power. Conventionally, all inverter circuits were operated even during periods where the solar panels are generating little power (low output periods). For this product, however, Fuji Electric has devised a way to optimally control the number of inverter circuits according to the output status. As a result, the power generation efficiency at low output (at 5 to 30% of rated power) was improved by 0.5 to 3.5 points compared with the conventional system.

Another noteworthy technological strength of Fuji Electric's PCS is the IGBT module, a power semiconductor that it produces in-house. "Our strength is power generation efficiency that is much higher than that of conventional products, which we achieve by constructing three-level inverters using semiconductors we manufacture ourselves," says Naoki Kuze, who is in charge of power supply development in Fuji Electric's Power Device Development Department.

Focusing on Southeast Asia, where demand is expected to grow. Contributing to the spread of clean energy.

person in charge of structural development,

Power Device Development Department, Fuji Electric

person in charge of power supply development,

Power Device Development Department, Fuji Electric

It has been decided that the newly developed 2500 kVA PCS will be used in Fuji Electric’s first overseas solar power generation project received as an EPC jointly with an overseas subsidiary. Other negotiations are moving forward as well, making for a relatively smooth start despite fears of economic downturn due to the global COVID-19 pandemic.

Speaking about expectations for expanding opportunities for PCSs, Kansuke Fujii, head of Plant Sales Technology at Fuji Electric, says, "Southeast Asian demand for electric power will increase in the future, but it will be difficult to meet it with thermal power generation. That means there will be a need to utilize renewable energy." While cooperating with the solar power plant EPC project, Fuji Electric will accelerate its business expansion in the rapidly growing Southeast Asian market and contribute to the spread of clean energy.

-

*

-

This article was created based on the content of the interview in October 2020.