Solutions and Case Studies

World’s top share! Fuji Electric’s geothermal power generation equipment

Geothermal power generation is attracting attention as a clean energy source.

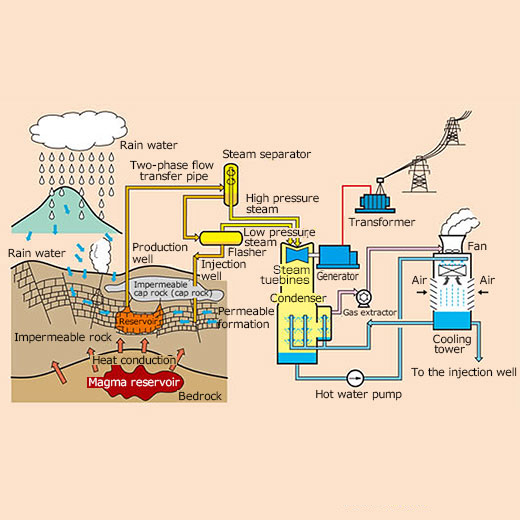

Generating electricity using geothermal energy from the magma reservoir

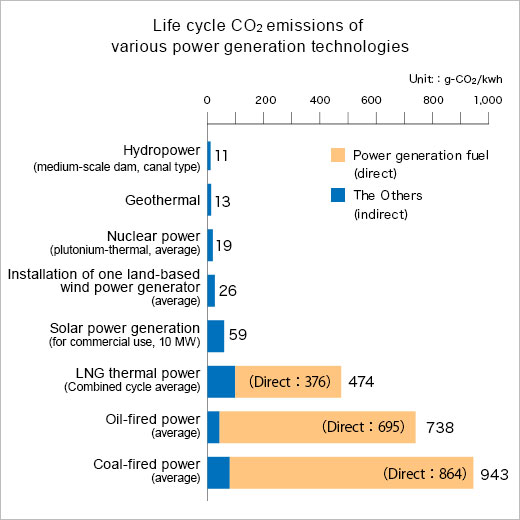

Life cycle CO2 emissions of various power generation technologies

-

Note 1

-

The life cycle CO2 emissions in the figure are the “average life cycle CO2 emissions by each category of technology”, which is derived from the life cycle CO2 emissions per the lifetime power generation calculated for each category of technology, weighted and averaged by the total installed capacity of the plants belonging to each technology category at the end of FY2008.

-

Note 2

-

Nuclear power calculations include spent fuel reprocessing, plutonium-thermal utilization, high-level radioactive waste disposal, etc.

-

Source:

-

Created based on "Comprehensive Assessment of Life Cycle CO2 Emissions fromPower Generation Technologies in Japan", Central Research Institute ofElectric Power Industry, July 2016.

Geothermal power generation is a power generation method that makes effective use of geothermal energy (underground hot water and steam) found in locations where the Earth's magma is relatively close to the Earth's surface.

This power generation method emits almost no pollution, and the use of this energy is attracting attention as a renewable clean energy as the steam is condensed and, along with the hot water, is restored to underground after use. In addition, compared to other renewable energy sources such as solar and wind power, which are affected by weather conditions, geothermal power generation enables a stable means of power generation, and it plays an important role as a baseload power source.

Fuji Electric has received orders for a total of 84 geothermal turbines generating 3,469 MW (the world’s top share since 2000).

History of Fuji Electric’s geothermal power generation business

| 1957 |

Establishment of thermal power business division |

|---|---|

| 1960 Delivery of geothermal turbine (first domestic unit) |

Hakone Kowakien, Japan, 30 kW

|

| 1980 |

Delivery of geothermal turbine (first overseas unit) |

| 2008 |

Delivery of Fuji Electric’s largest capacity double-flash* system with a single-unit, 95,720 kW steam turbine |

| 2009 |

Delivery of Fuji Electric’s largest capacity single-flash* system with a single-unit, 117,000 kW steam turbine |

| 2010 Delivery of single unit of the world’s largest capacity triple-flash* system |

Nga Awa Purua, New Zealand, 139,000 kW

|

| 2013 |

Delivery of Fuji Electric’s first axial-flow exhaust unit |

| 2017 Delivery of Fuji Electric’s first geothermal binary cycle** plant (one of the largest geothermal plants in Japan) |

Takigami Binary, Kyushu, Japan, 5,050 kW

|

-

*

-

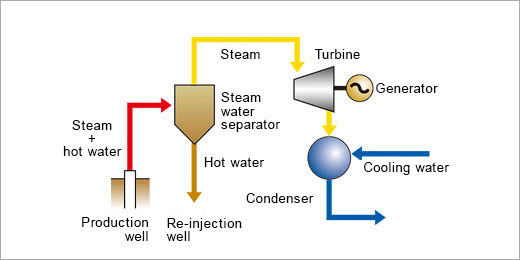

Flash system: A method of generating electricity by rotating a turbine using steam separated from geothermal fluid that is a mixture of steam and hot water.

-

**

-

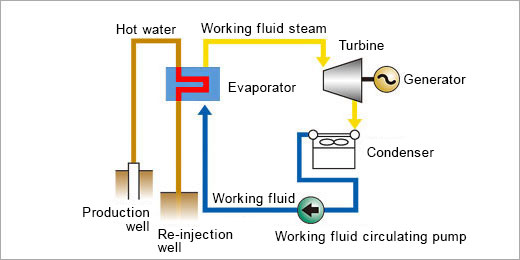

Binary cycle system: A method of generating electricity by rotating a turbine using steam from a low boiling point fluid that is heated and evaporated by geothermal fluid.

Fuji Electric has received orders in Japan and overseas for 84 units (9 units in Japan) of geothermal steam turbine power generation equipment generating 3,469 MW, and has the world’s largest share of orders (36%) since 2000.

(1)

Our geothermal power generation equipment contributes to the reduction of approximately 244,000 tons of CO2 emissions per year when calculated as an alternative to thermal power.(2) This is equivalent to monthly CO2 emissions of about 60,000 households.(3) As a front runner of geothermal power generation technology, Fuji Electric will continue to work on the expansion of clean energy technologies and products, and contribute to the reduction of CO2 emissions in society.

(1) Calculated based on our in-company research data from 2000 to November 20, 2019.

(2) CO2 emission reduction = annual power generation amount × CO2 emission factor; CO2 emission factor: 0.619 kg − CO2/kWh (power generation weighted average) (Source: Liaison Group of Japanese Electrical and Electronics Industries for Global Warming Prevention); Calculated per 50 MW.

(3) Source: Calculated based on “FY2018 Carbon Dioxide Emissions from Households” (in Japanese) on the website of the Greenhouse Gas Inventory Office of Japan (GIO), Japan Center for Climate Change Actions (JCCCA).

Fuji Electric’s three strong points

1. Extensive equipment lineup including both flash and binary cycle systems

Flash system

-

A method of generating electricity by rotating a turbine using steam separated from geothermal fluid that is a mixture of underground steam and hot water.

-

Geothermal power generation method in general use.

Binary cycle system

-

A method of generating electricity by rotating a turbine using steam from a low boiling point working fluid that is heated and evaporated by geothermal fluid from underground.

-

Compatible with heat sources in the low-temperature range.

There are mainly two types of technology in use for geothermal power generation: flash and binary cycle systems. Fuji Electric’s strong point is that we are the only company in the industry to have a product lineup and a track record including both flash and binary cycle systems. This enables us to be able to provide solutions for customer requirements under various conditions.

2. Design and manufacturing technologies that enhance the reliability of geothermal turbines

Steam turbines for geothermal power generation are prone to corrosion and wear, and thus require a high degree of durability.

Another Fuji Electric strong point is that we can design and manufacture steam turbines that are resistant to corrosion and wear by optimally designing from the material selection and shape of steam turbines according to on-site conditions such as the ratio of components contained in the geothermal steam and the amount of gas.

Many geothermal power plants using Fuji Electric's equipment have been operating for 30 years or longer after initial startup thanks to our steam turbine design and manufacturing technologies that make the most of our many years of experience and expertise.

3. High-level engineering capabilities to cover the entire power plant

We have expanded our onshore and on-site maintenance and services for plants that are installed in distant overseas locations to enable the early restoration of the equipment. (The photo shows a mobile lathe at one of our group companies that has expertise in onshore and on-site repairs.)

Fuji Electric has high-level engineering capabilities to undertake the overall engineering, procurement, and construction (EPC) work for geothermal power plants, including the delivery and installation of the geothermal power generation equipment.

We provide maintenance and services to support the continuous operation of power plants by giving top priority to customer requirements and providing maintenance and overhauls(4) of geothermal turbine equipment, upgrade proposals including higher efficiency equipment, and prompt recovery in the event of an accident.

In the future, we will continue to contribute to the spread of geothermal power generation by developing technologies that optimize operations and maintenance (O&M), such as remote monitoring, predictive maintenance technology, etc., by utilizing IoT and AI technologies and packaged geothermal power generation equipment, such as organic Rankine cycle (ORC) technology, that can be applied for installations that require small capacity and short construction periods.

(4) An overhaul involves the work of disassembling mechanical products into their parts, cleaning and reassembling them, with the objective of improving their performance closer to that of new products.