MICREX-SX SPF Series

Features

The unit has impressive sequence processing performance for machine control operations, as well as enhanced data processing capabilities.

Instruction execution time is as fast as 0.3μs for basic instructions and 0.87μs for data instructions, enabling the unit to achieve the highest performance of its class.

This contributes to improving production capacity.

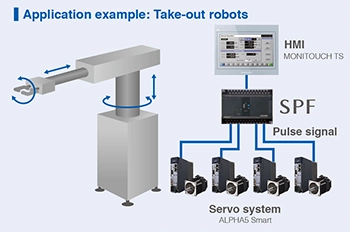

This function is compatible with a 200 kHz, 4-axis pulse output. It can be utilized for increasingly sophisticated and high-accuracy positioning.

SPF has two types of basic units: the high-functionality type basic unit (Type: NA0PA), which is suitable for positioning control while connected to a servo system; and the standard type basic unit (Type: NA0PB), which is suitable for the control of general equipment not supported by a servo system. It's possible to select a basic unit depending on applications.

RS-232C, RS-485 and Ethernet communication can be established by simply mounting a small board to the basic unit.Communication functions can also be achieved through use of an extension unit on the left side.

Two types of programming tools can be selected depending on applications. There are two types of programming tools: Expert, which is compliant with the international standard IEC 61131-3 for PLCs; and Standard, which mainly consists of ladder logic. Function blocks (FB) can also be used corresponding to the control applications.

With enhancements to the functional system and increased data processing, the unit comes with a large-capacity program and data memory.

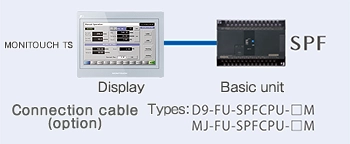

SPF can be connected to the MONITOUCH via the loader port. It does not require any special communication equipment.

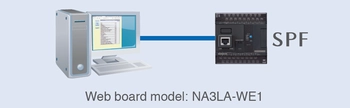

Data can be read and written through a Web browser of a PC.

We offer a unique lineup of modules compatible with load cells used for metering and weighing systems, tank scales, etc. They can be applied to wide range of applications such as cement plants.

A calendar function comes standard as an essential function for monitoring machinery and systems.