Features

-

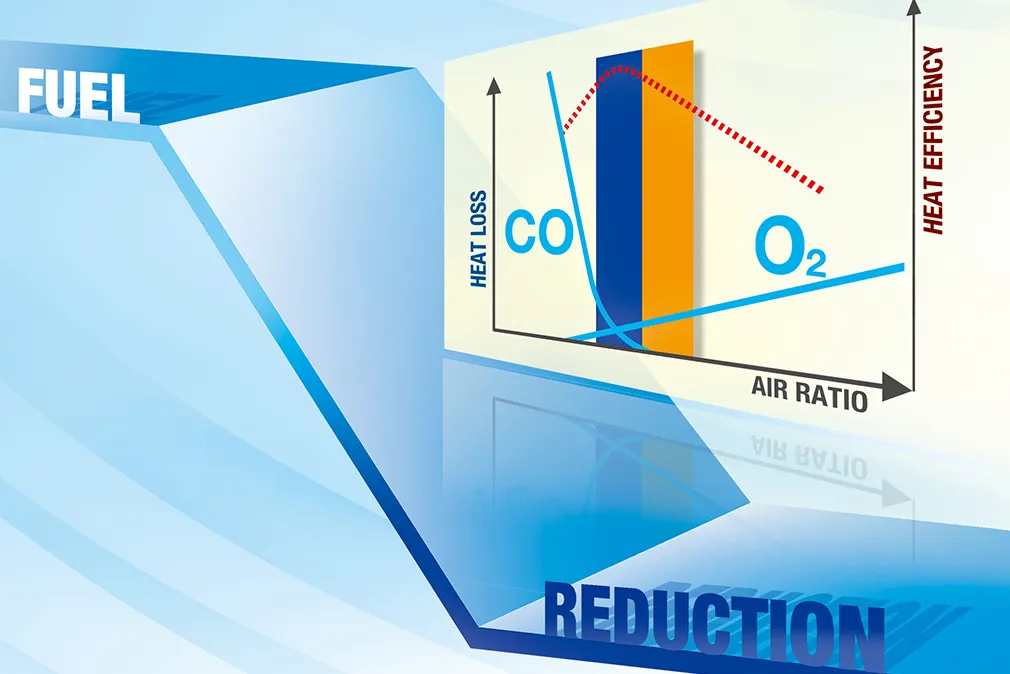

Addition of independently developed optimal combustion logic for boiler combustion control (Using thermodynamics and combustion theory logic for boiler control)

-

Active control of the generation of trace amounts of carbon monoxide (CO) in the boiler exhaust gas improves combustion efficiency

-

Real-time sensing technology using a fast response laser CO analyzer

-

Exhaust gas CO block control prevents generation of excessive CO in the exhaust gas regardless of changes in the operating condition of the boiler

-

Suppression of CO generation to within regulated values when exhaust gas CO concentration regulations exist

Improved boiler fuel costs up to 1%

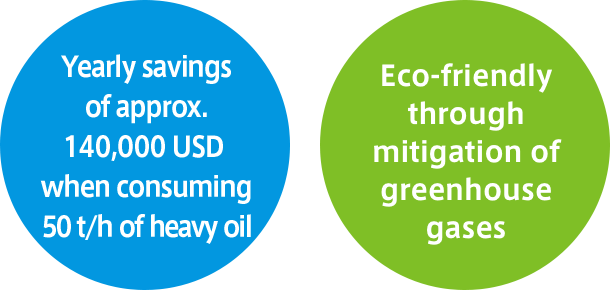

Improving the combustion efficiency has greatly contributed to cost reduction by enhancing boiler performance, while also reducing fuel costs up to 1%. This solution also contributes to protecting the global environment since it leads to reduction in greenhouse gases.

Japanese Patent No. 6135831

Estimated benefit of fuel reduction (Unit: ten thousand USD per year)

-

*1

-

The benefit of fuel reduction is estimated based on a 1% fuel consumption improvement. It differs depending on factors such as the exhaust gas temperature and/or the reduction in the amount of the exhaust gas O2 concentration of utilized boiler.

-

*2

-

Fuel prices make use of the following data. Heavy oil: 0.4 USD/R; LNG: 0.46 USD/kg; Coal: 0.11 USD/kg

-

*3

-

Boiler operating hours: 7920 hours (330 days a year)