Research & Development

R&D Projects

Sealed High-Voltage Contactors

# Business Groups & Production Technology Groups # Electric Distribution & Control Components # Safety and Security

-

Sealed contact structure that facilitates compactness and high breaking performance

-

Original contact structure that enables high overcurrent withstand capability and consistent forward and reverse breaking performance

The spread of direct-current power distribution systems and electric vehicles has caused an increase in the demand for direct-current circuit hvcs that are smaller in size, safer and contact reliable. This recently developed sealed high-voltage hvc has its contact block located in a sealed capsule enclosed with breaking gas in order to achieve improved breaking performance, smaller size and high contact reliability.

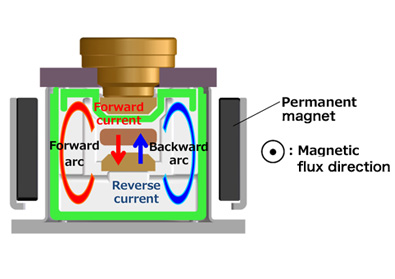

Even in the event that overcurrent is generated by short circuit due to failure or malfunction, the original contact structure maintains its contacting point contact state, and this enables it to achieve the industry’s highest overcurrent withstand capability of 20,000 A, while significantly reducing the risk of fire and explosion. Furthermore, it also achieves non-polarization for the main circuit and a consistent forward and reverse direction breaking performance.

-

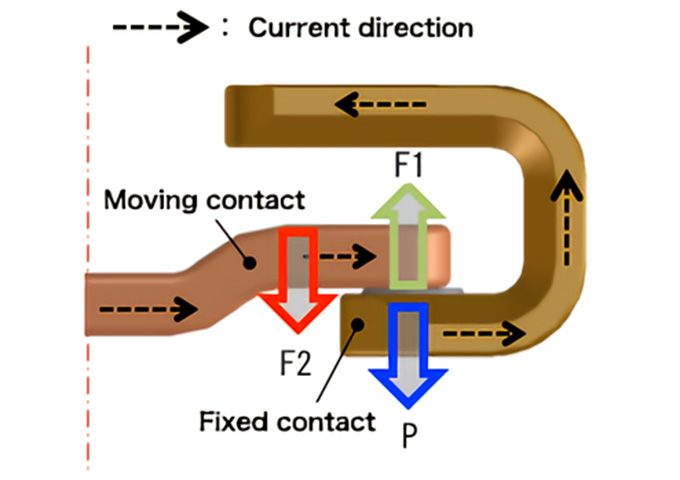

P

-

Contacting point contact pressure

-

F1

-

Electromagnetic repulsion force generated to the contacting point contact block

-

F2

-

Electromagnetic force of the parallel conductor acting on the moving contact

Contact structure and design principle for maintaining the contacting point contact state during large current-carrying

Topics

-

May 24, 2017

-

Press Release: Launch of

Sealed High-Voltage Contactors”

-

May 25, 2017

-

Nikkan Kogyo Shimbun (p.10),

The Denki Shimbun (p.4)

-

May 30, 2017

-

Nikkei Sangyo Shimbun (p.20)