One Step Ahead! Fuji Electric's Fundamental Technologies

We provide an overview of our latest fundamental technologies that enhance our product development capabilities.

Thermo-Fluid Control Technology

Thermo-fluid control technology to understand and control the phenomenon of airflow and heat transfer

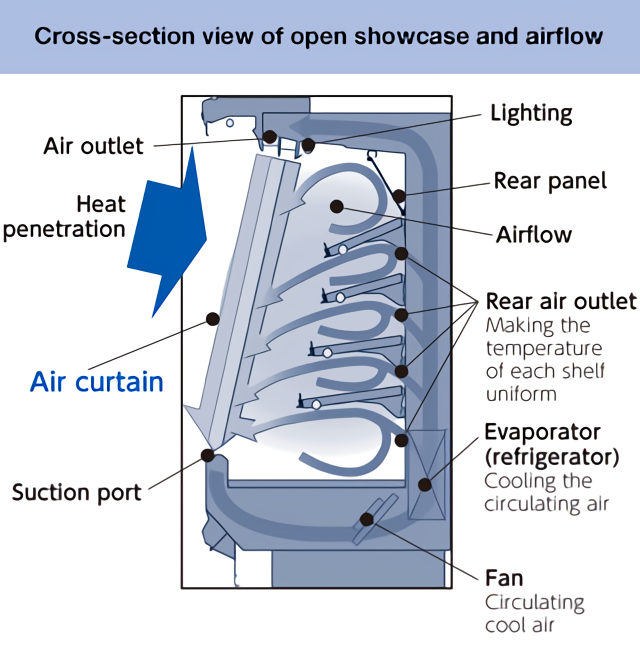

Thermo-fluid control technology is used to understand and control the flow of gas and liquid as well as heat transfer from a viewpoint of a goal such as conserving energy. This technology is used in food and beverage display cases at supermarkets and convenience stores, in vending machines, and the like. If an open showcase has no door on the front, just as in open air, a great deal of heat will enter.

In order to block this warm air from entering, the thermo-fluid technology is needed to properly control the flow of air with a sheet of air known as an air curtain.This technology is currently used at cold storage warehouses, plant factories, and the like.

Developing a simulator to predict the growth of frost and achieving significant energy saving

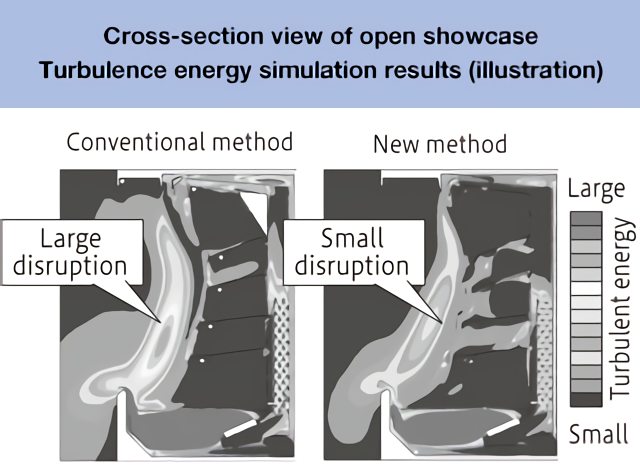

Since the air curtain is not visible, we conduct visualization experiments using laser beams and thermo-fluid simulations to optimize the flow of air. In these simulations, we can use a computer to calculate the wind speed, temperature, humidity, airflow turbulence and the like to cool the inside of the showcase efficiently. There are numerous design items that are related to the efficiency of the showcase, and sometimes dozens of simulation patterns are needed.

Focusing on the fact that frost deposits (frost formation) cause changes in airflow, we developed a frost formation simulator to predict the growth of frost. Open cases using this technology together with the airflow control technology developed over many years achieved energy saving that is more than 30% greater than conventional cases.

In addition, we built a mechanism that allows users to automatically create analytical models of showcases simply by entering parameters in Microsoft Excel. Conventionally, analytical models were created by specialists, and while this should take one or two weeks, users can now perform analysis easily in just a few hours without special knowledge.

Voices of developers

Sharpening the senses and taking up the challenge of new innovation!

We are striving to develop technologies that contribute to saving energy, raising the themes of preventing global warming and safe and secure food. By developing simulation technologies and the like, we can develop products now more efficiently than ever, but we still highly value the five senses. We are always thinking about points to improve, such as by feeling the air flow on our hands, cheeks and other parts of our bodies in front of the actual machine all day in the lab or visiting supermarkets to actually feel the wind. We will continue to apply thermo-fluid technology in a variety of products going forward as well.

The article and the affiliations are at the time of coverage.