One Step Ahead! Fuji Electric's Fundamental Technologies

We provide an overview of our latest fundamental technologies that enhance our product development capabilities.

Noise Simulation Technology

Using a computer program to reproduce noise generation and enable verification in the initial stage of development

Using a computer program to reproduce noise generation and enable verification in the initial stage of development

Contributing to better lives and working environments by reducing product noise

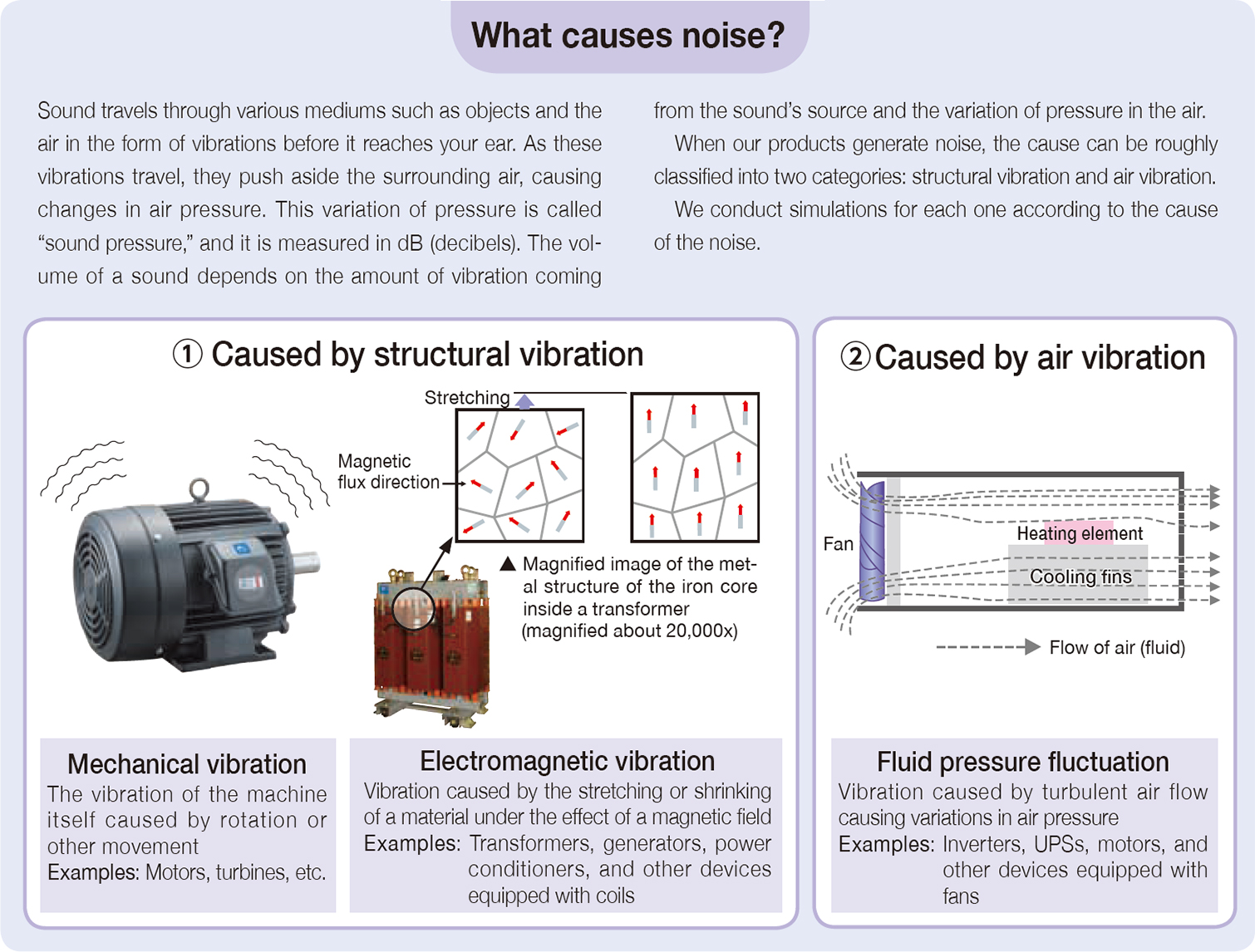

In our daily lives, we are exposed to a variety of noises from construction sites, cars, and factory production activities. In order to manage the stress on residents and factory workers, there are established laws and regulations on noise that companies must comply with.

Fuji Electric is working on measures to reduce the noise from its products. As an example, let’s look at electrical components with cooling fans. Reducing the noise of the components leads to reducing the noise of the equipment on which they are mounted, including railroads and production equipment such as machine tools.

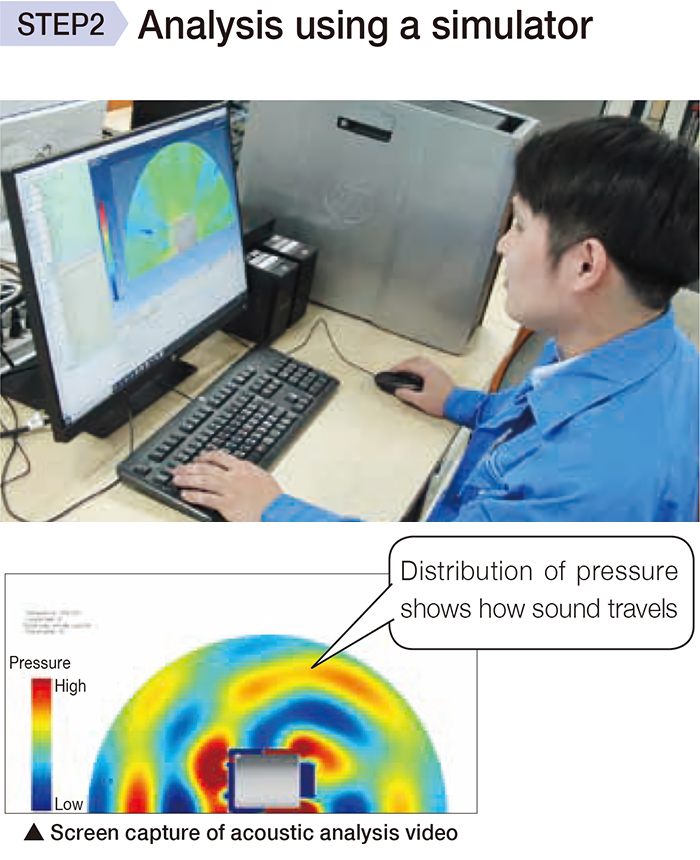

We can achieve this with our noise simulation technology. In noise simulation, we use a computer program to model the product and the surrounding environment, which allows us to visually verify the generation and magnitude of sound and how it propagates in a way that is easy to understand.

Our approach

In order to conduct a simulation, we first estimate the factors that affect noise based on literature and reports on our products. Then, we conduct a test using a proof-of-principle machine with a simplified structure, and we use the results (data) as the basis for modeling shapes or physical phenomena on a computer. Here, we use a transformer as an example of an electromagnetic vibration simulation.

A transformer is a product with two coils wound around an iron core to vary the voltage depending on the number of windings of the two coils. When a current is run, a magnetic field is generated around the iron core and coils. The electromagnetic force generated there causes deformation and vibration of surrounding parts and materials, which may result in noise.

Therefore, we first construct a proof-of-principle machine for the iron core and coils, and we actually run electricity and measure items such as vibration, deformation, and magnetic flux density. The iron core has a laminated structure with thin iron sheets stacked up like layers of puff pastry. To build a simulation model, we use this structure of stacked iron sheets and a variety of factors that affect noise, including the coil winding method and the number of coil windings.

Next, we use a simulator for calculation based on the model we have built. Here, we present a simulation of noise generated by fluid pressure fluctuation.

This simulation allows acoustic analysis of motors, vending machines, and inverters equipped with cooling fans. For example, motors get hot when they are driven continuously, so they need a cooling fan that blows air to cool their surface. Then, the air flow around the cooling fan is disturbed, so the air vibrates, generating noise.

That’s why we use a simulator to visualize the flow of air (fluid) that causes noise and to analyze where and how the generated sound travels. By applying this technology in the initial stage of development, we can greatly reduce the time and cost required to deal with product noise.

Voices of developers

In the Digital Engineering Department, we are also developing simulation technologies in a wide range of fields, including fluids, structures, electromagnetics, mechanics, and drive control. We also undertake product simulations at the request of other departments, and provide support for building programs and introducing software so they can perform simulations on their own.

The article and the affiliations are at the time of coverage.