One Step Ahead! Fuji Electric's Fundamental Technologies

We provide an overview of our latest fundamental technologies that enhance our product development capabilities.

Insulating Material Development

“Ultimate recipe” to improve the quality of insulation materials essential to all electrical products

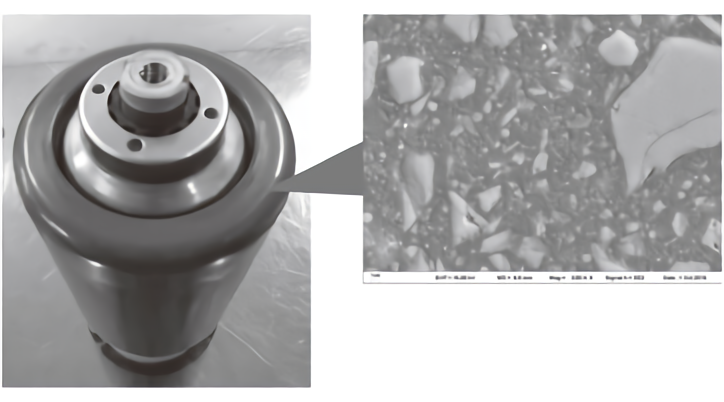

Top: Type of filler reconsidered for improving strength of resin

Insulation materials are used for a variety of products such as substation equipment, power semiconductors, inverters and motors. Insulation of conductors that conduct electricity and circuit components from the surroundings work to prevent device failure caused by discharge (arcing, etc.). Various insulation methods including air, oil, and gas are available, but the Polymer & Insulation Group is doing research mainly on insulation by resin.

Resin materials are made by mixing the base resin, curing agent, catalyst, plasticizer, colorant, filler, flame retardant, and other elements. In the same way that the taste of a dish depends on how the ingredients are combined and how much seasoning is used, with resin, the difference in the molecular structure and composition may result in significant variation of insulation performance and strength. Out of an infinite number of combinations, the “ultimate recipe” is created.

High-strength resin developed to reduce the size of VCBs

At present, we are focusing on the development of resin materials and molding methods for vacuum circuit breakers (VCBs) used for cubicle-type gas insulated switchgears (C-GIS). The use of resin allows the distance required for insulation to be reduced to 1/10 as compared with air insulation. With a shorter insulation distance, the interval between neighboring vacuum valves in a VCB can be reduced, which can downsize the equipment. However, the resin was not strong enough to be used for VCBs, and so air has been used for insulation.

Accordingly, we embarked on material development to improve the strength of resin. Further improvement of strength required reconsideration of the ingredients, including the filler, which is decisive to mechanical strength, and we conducted repeated studies to create a new recipe. In 2016, a resin material for 24-kV VCBs was developed, and it can be used to reduce the size of VCBs by 50% to 60%. We are now studying application to solid bus bars of 84-kV VCBs and 24-kV and 36-kV C-GIS.

This fiscal year, we started to work on improving the insulation properties of resin. To that end, understanding the behavior of electricity is necessary and we are developing simulation technology (quantum chemistry calculation) that allows calculation at an atomic or molecular level, which is smaller than nm (1/1,000,000 mm). By improving the insulation properties of resin to more than double for application to GIS, the size of a substation can be halved.

Voices of developers

We contribute to environmental protection by material development

In the near future, we intend to develop a material design tool (for simulation) based on computational science for improving various characteristics as a whole, including strength, insulation and thermal resistance.

We are also working on the development of recyclable plastics and resins made of natural materials such as plants. Their commercialization of them leads to reduced CO2 emissions, which contributes to environmental protection. It would be exciting to see them used for insulation materials and inverter housings.

The article and the affiliations are at the time of coverage.