One Step Ahead! Fuji Electric's Fundamental Technologies

We provide an overview of our latest fundamental technologies that enhance our product development capabilities.

Applied Optical Technology of Analyzers

Measurement and control technology contributing to cost reduction for business operators

In waste incineration facilities, exhaust gas containing hazardous substances (such as hydrogen chloride) is generated during combustion. To comply with legal emissions standards, business operators remove hazardous substances by adding a neutralizing agent to exhaust gas, but reducing the cost of this neutralizing agent is an issue. Fuji Electric has developed a system solution consisting of control software and measuring equipment, which measures the components of exhaust gas to provide optimum control of the amount of the neutralizing agent added, thereby contributing to cost reduction for business operators. The key component in this system is a laser gas analyzer.

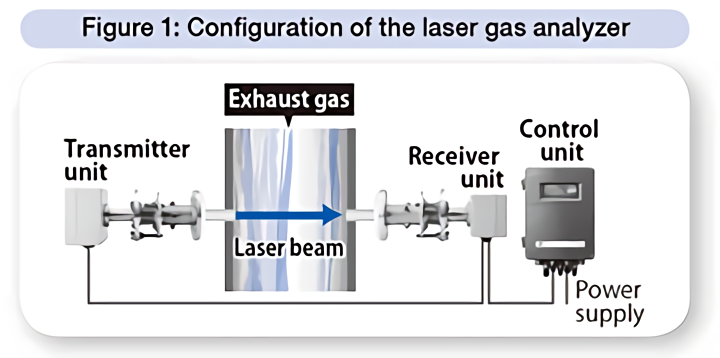

This product measures the concentration of gas in real time using a laser beam emitted by equipment installed directly in the piping (Figure 1). The laser beam from the transmitter unit is absorbed into the gas components (such as hydrogen chloride and water) in the piping to reach the receiver unit. The received light intensity (representing the intensity of the laser beam that has reached the receiver unit) can be measured to obtain the concentration of the gas.

The first in the world to develop a technique to simultaneously measure two components with one unit

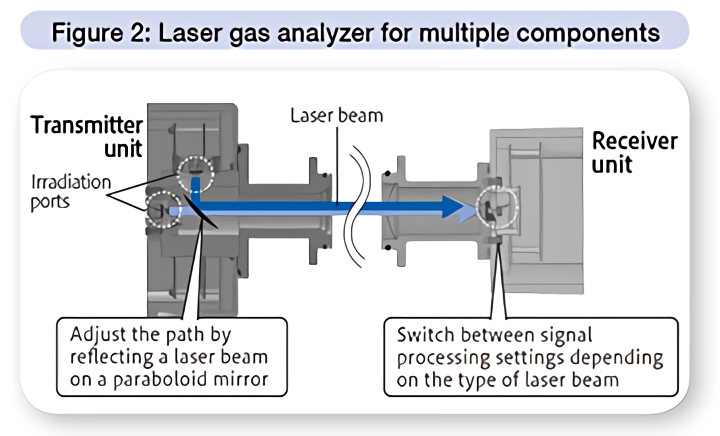

In 2012, we became the first in the world to develop a technology to allow simultaneous measurement of two gas components using one analyzer. Different gas molecules absorb light at different wavelengths (absorption wavelengths), and laser beams with absorption wavelengths suited for the gas to be measured need to be emitted. Back then, two analyzers were needed to measure two components, which made caused anxiety for customers about higher introduction costs and other issues.

For these reasons, we developed a time-division (switching) system that can measure two components simultaneously. It does this by emitting laser beams that react to the two components respectively while switching between signal processing settings at intervals of milliseconds. The transmitter unit is provided with an internal paraboloid mirror (a type of concave mirror) to make adjustments so that the beams emitted from the two irradiation ports travel along the same path. The receiver unit is capable of switching between different signal processing settings depending on the type of laser beam, which has allowed us to integrate the functions of measuring two components into one unit (Figure 2). To improve resistance to vibration and high temperatures as well as to achieve high-speed, high-accuracy measurement, we used an optical simulator for repeated verification and set our sights on commercialization while working with the design department of the factory.

Voices of developers

Facing on-site issues head-on to develop new products

When we conducted a field test on site, we found that the high-temperature, highconcentration vapor in the combustion gas had an effect on the absorption wavelengths of the laser beams, impacting the measurement results beyond what we had assumed. It is natural for issues to occur in an environment that cannot be reproduced in in-house tests, and facing such issues head-on helps us to develop products and build up technical expertise. Through extensive literature research and experiments and by devising a method of signal correction processing capable of reducing the impact on measurement accuracy, we successfully resolved the issue.

In the future, we intend to continue developing key strong components for bringing out system solutions that will help solve customers’ problems.

The article and the affiliations are at the time of coverage.