Corporate Data

HISTORY

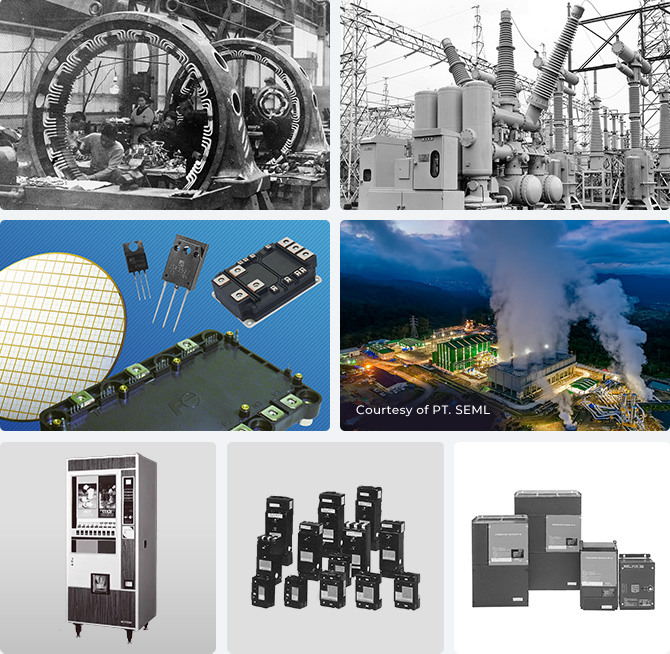

“Power semiconductors”, “Geothermal Power Generation”,

“Hot & Cold Cup vending machine”, “Earth leakage breaker”, “General purpose inverters”

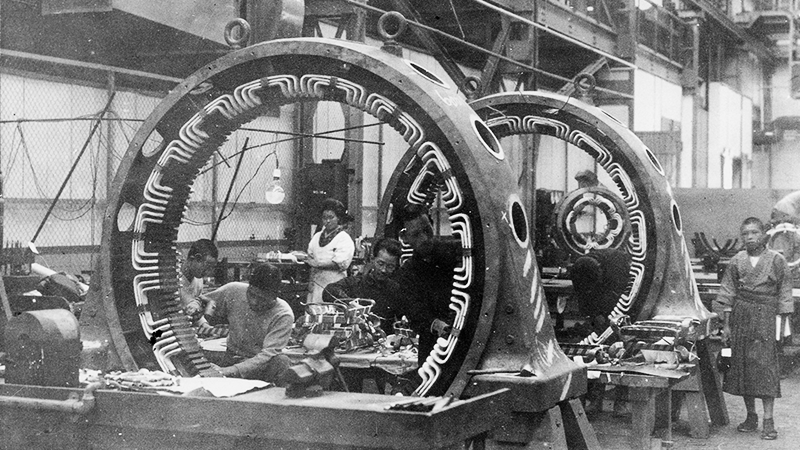

1923-1944

In August 1923, our predecessor Fuji Electric Manufacturing Co., Ltd. was established through the capital and technical partnership of Furukawa Electric of Japan and Siemens of Germany. Amid the ongoing modernization of industry in Japan, we contributed greatly by offering products such as motors, transformers, generators, circuit breakers, and measuring instruments. This facilitated mechanization in the mining, steel, and chemical sectors and helped stabilize electric power supply.

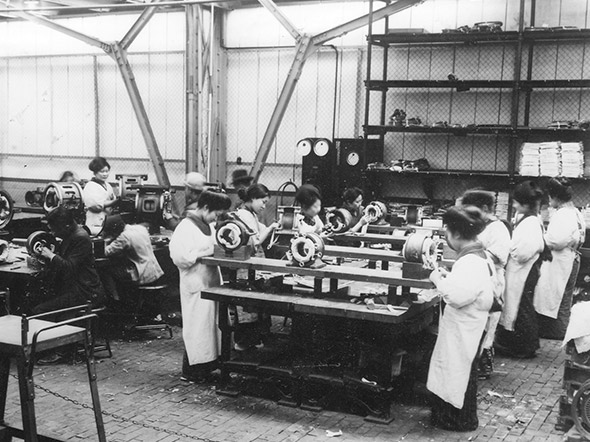

1945-1973

We produced general-purpose electric motors, watt-hour meters, and other equipment for postwar reconstruction. To meet the increasing demand for power due to economic growth, we have taken on the challenge of increasing the scale of hydro power plants and thermal power stations, as well as manufacturing facilities for Japan's first nuclear power station. We also released transformers and circuit breakers for substation and distribution facilities that had been enlarged. We supplied measurement and control equipment to steel works and water and sewage treatment facilities to automate operations. Our compact, lightweight, high-performance drive units were provided for the 1st-generation Shinkansen to support growth in transportation. We also offered home appliances, and their heating and cooling technology led to manufacturing of beverage vending machines.

1974-1991

The first oil crisis increased interest in new energies, energy saving, and productivity improvement. We developed solar cells and fuel cells, and received our first order for overseas geothermal power generation equipment. We advanced our core power electronics technology and provided many inverters and power electronics products equipped with our unique power semiconductors including power transistors, which were the first in the world to begin manufacturing in 1975, contributing to energy saving. Our automation systems, such as the world’s first EIC integrated control system (*) largely served to develop the industry.

-

*

-

An integrated system that combines three control systems: electrical (E), instrumentation (I), and computer (C)

1992-2012

New challenges arose with the burst of Japan’s bubble economy and the necessity to reduce greenhouse gas emissions. We established our Basic Polices on Environmental Protection in 1992 to promote new environmentally friendly products and technologies. In 2002, we released environmentally friendly C-GIS that did not use SF6 gas. In the same year, our phosphoric acid fuel cell won the New Energy Award. We developed power conditioning systems for mega solar power plants designed for the 2012 FIT (*) to reduce the environmental load of products.

-

*

-

Feed-in Tariff Scheme for Renewable Energy

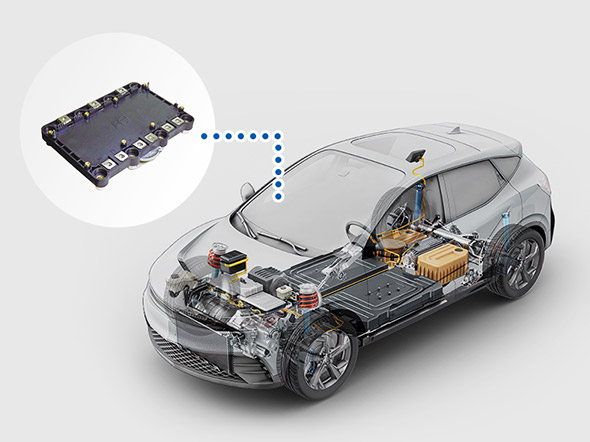

2013-

Amid the worldwide initiative to combat global warming, we launched a large-capacity UPS for data centers and a main power converter for Shinkansen, which use our energy-efficient power semiconductors. We also provide power semiconductors to the EV and renewable energy sectors. We also use IoT and AI to make factories smarter, and to stabilize operations and save energy. We use virtual power plant (VPP) technology to stabilize power supply and make power infrastructure more resilient.

MOVIE

Discover the Century of

Transformation: A Journey

with Fuji Electric.